User Manual

3200 Series

54 Part No HA028651 Issue 11.0 July-12

11.

Control

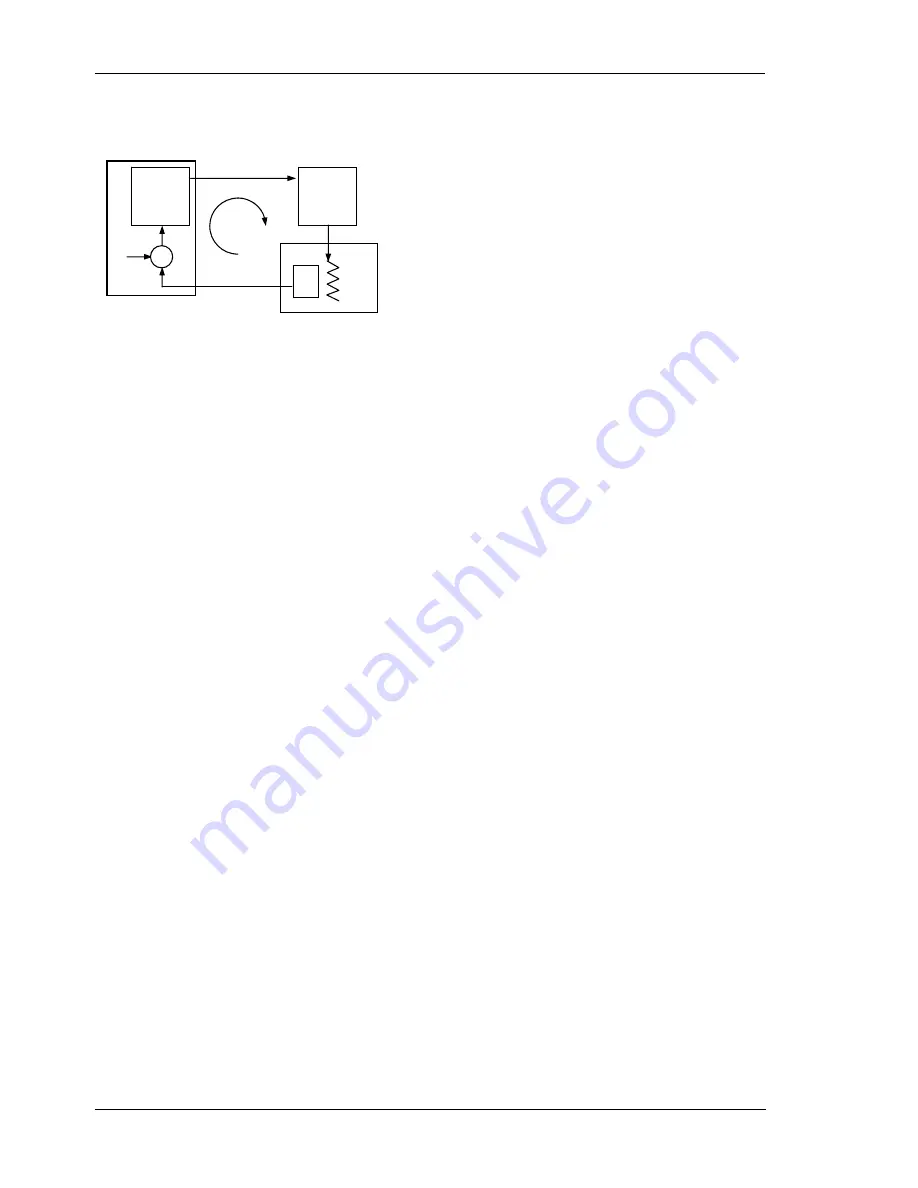

Parameters in this section allow the control loop to be set up for optimum control conditions. An example of a

temperature control loop is shown below:-

The actual temperature measured at the process (PV) is connected

to the input of the controller. This is compared with a setpoint (or

required) temperature (SP). If there is an error between the set

and measured temperature the controller calculates an output

value to call for heating or cooling. The calculation depends on

the process being controlled but normally uses a PID algorithm.

The output(s) from the controller are connected to devices on the

plant which cause the heating (or cooling) demand to be adjusted

which in turn is detected by the temperature sensor. This is

referred to as the control loop or closed loop control.

11.1

Types of Control

Three types of control loop may be configured. These are On/Off control, PID control or control of motorised valves

11.1.1

On/Off Control

On/Off control is the simplest means of control and simply turns heating power on when the PV is below setpoint and off

when it is above setpoint. As a consequence, On/Off control leads to oscillation of the process variable. This oscillation

can affect the quality of the final product and may be used on non-critical processes. A degree of hysteresis must be set

in On/Off control if the operation of the switching device is to be reduced and relay chatter is to be avoided.

If cooling is used, cooling power is turned on when the PV is above setpoint and off when it is below.

It is suitable for controlling switching devices such as relays, contactors, triacs or digital (logic) devices.

11.1.2

PID Control

PID, also referred to as ‘Three Term Control’, is an algorithm which continuously adjusts the output, according to a set of

rules, to compensate for changes in the process variable. It provides more stable control but the parameters need to be

set up to match the characteristics of the process under control.

The three terms are:

Proportional band PB

Integral time TI

Derivative time TD

The output from the controller is the sum of the contributions from these three terms. The combined output is a

function of the magnitude and duration of the error signal, and the rate of change of the process value.

It is possible to turn off integral and derivative terms and control on proportional only (P), proportional plus integral (PI)

or proportional plus derivative (PD).

PI control might be used, for example, when the sensor measuring an oven temperature is susceptible to noise or other

electrical interference where derivative action could cause the heater power to fluctuate wildly.

PD control may be used, for example, on servo mechanisms.

In addition to the three terms described above, there are other parameters which determine how well the control loop

performs. These include Cutback terms, Relative Cool Gain, Manual Reset and are described in detail in subsequent

sections.

Control Output

Measured

temperature

Heater

Setpoint

Control

Method

PV

Error

Power

Regulator

Control

Loop

Summary of Contents for XST-2-0-12-1V1-E28

Page 16: ...12 FURNACE TROUBLE SHOOTING ...

Page 27: ...ɸ ...

Page 28: ...ɸ ...

Page 29: ......

Page 30: ......

Page 31: ...3216 3208 3204 User Manual 3200 Range Process Controller HA028651 11 Aug 2012 ...

Page 170: ...User Manual 3200 Series 138 Part No HA028651 Issue 11 0 July 12 21 Certificate of Conformity ...

Page 171: ......

Page 173: ...Model 2416 Process Controller User Manual Part No HA025041_12 Date August 2014 ...

Page 174: ...This page is intentionally blank ...

Page 259: ...This page is intentionally blank ...