3200 Series

User Manual

Part No HA028651 Issue 11.0 July-12 59

11.2.3

Derivative Term ‘TD’

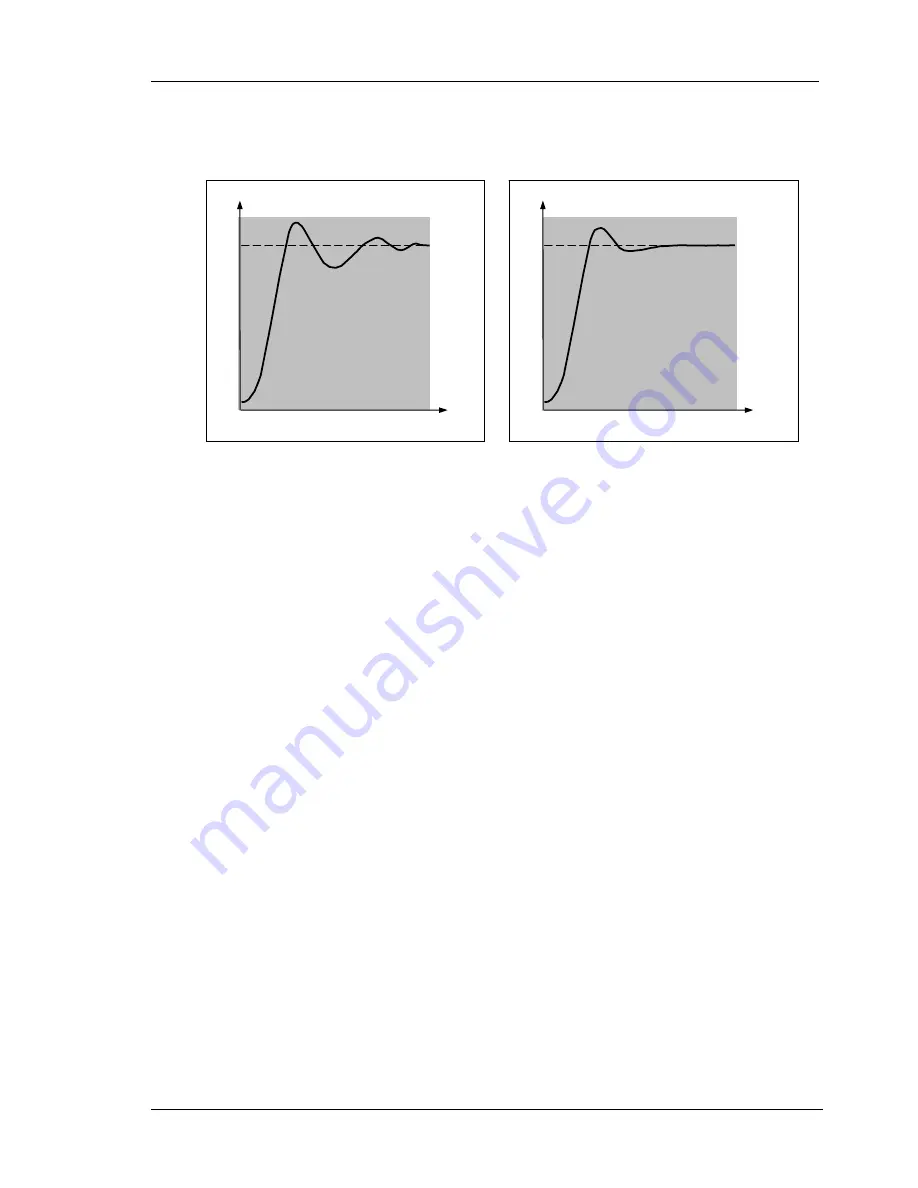

Derivative action, or rate, provides a sudden shift in output as a result of a rapid change in error. If the measured value

falls quickly derivative provides a large change in output in an attempt to correct the perturbation before it goes too far.

It is most beneficial in recovering from small perturbations.

The derivative modifies the output to reduce the rate of change of error. It reacts to changes in the PV by changing the

output to remove the transient. Increasing the derivative time will reduce the settling time of the loop after a transient

change.

Derivative is often mistakenly associated with overshoot inhibition rather than transient response. In fact, derivative

should not be used to curb overshoot on start up since this will inevitably degrade the steady state performance of the

system. Overshoot inhibition is best left to the approach control parameters, High and Low Cutback, section 11.2.5.

Derivative is generally used to increase the stability of the loop, however, there are situations where derivative may be the

cause of instability. For example, if the PV is noisy, then derivative can amplify that noise and cause excessive output

changes, in these situations it is often better to disable the derivative and re-tune the loop.

If set to Off(0), no derivative action will be applied.

In 3200 controllers derivative is calculated on change of PV. For applications such as furnace temperature control, it is

common practice to use Derivative on PV to prevent thermal shock caused by a sudden change of output as a result of a

change in setpoint.

11.2.4

Relative Cool Gain ‘R2G’

The proportional band parameter ‘PB’ adjusts the proportional band for the heating output. Relative cool gain adjusts the

cooling proportional band relative to the heating proportional band. If the rate of heating and rate of cooling are widely

different it may be necessary to manually adjust Relative Cool Gain to achieve the optimum settings for the cooling

proportional band. A nominal setting of around 4 is often used.

Note, This parameter is set automatically when Auto-tune is used unless the parameter ‘AT.R2G’ is set to ‘No’ - see

section 11.4.

Temperature

Time

SP

Propor Integral

response

Temperature

Time

SP

Response with derivative action

included

Summary of Contents for XST-2-0-12-1V1-E28

Page 16: ...12 FURNACE TROUBLE SHOOTING ...

Page 27: ...ɸ ...

Page 28: ...ɸ ...

Page 29: ......

Page 30: ......

Page 31: ...3216 3208 3204 User Manual 3200 Range Process Controller HA028651 11 Aug 2012 ...

Page 170: ...User Manual 3200 Series 138 Part No HA028651 Issue 11 0 July 12 21 Certificate of Conformity ...

Page 171: ......

Page 173: ...Model 2416 Process Controller User Manual Part No HA025041_12 Date August 2014 ...

Page 174: ...This page is intentionally blank ...

Page 259: ...This page is intentionally blank ...