3200 Series

User Manual

Part No HA028651 Issue 11.0 July-12 63

11.3.3

Automatic Tuning

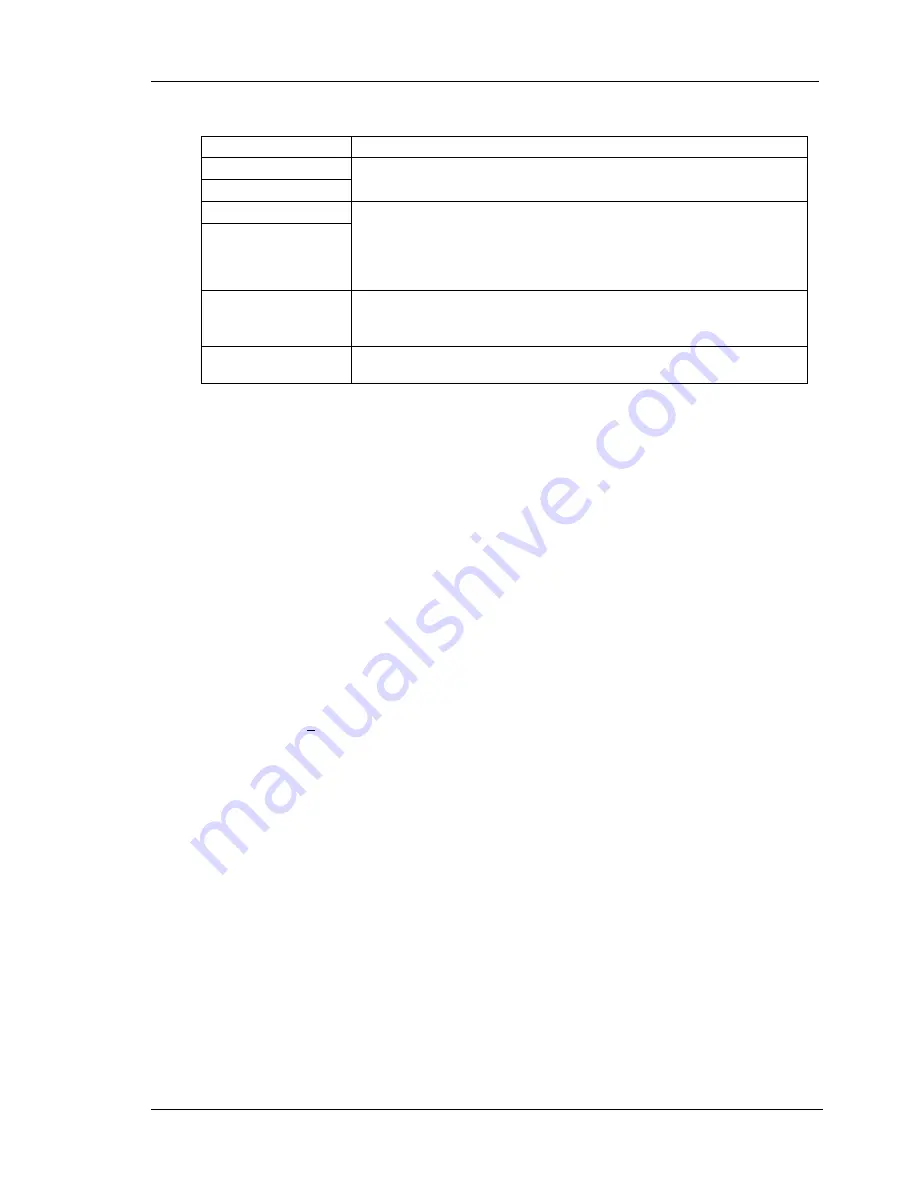

Auto Tune automatically sets the following parameters:-

Proportional Band ‘

PB’

Integral Time ‘

Ti’

If ‘

Ti

’ and/or ‘

Td

’ is set to OFF, because you wish to use PI, PD or P only control, these

terms will remain off after an autotune.

Derivative Time ‘

Td’

Cutback High ‘

CBHI’

If CBH and/or CBL is set to ‘

Auto’

these terms will remain at Auto after an autotune, i.e.

3*PB.

For autotune to set the cutback values, CBHI and CBLO must be set to a value (other than

Auto) before autotune is started.

Autotune will never return cutback values which are less than 1.6*PB.

Cutback Low ‘

CBLO’

Relative Cool Gain ‘

R2G’

R2G is only calculated if the controller is configured as heat/cool.

Following an autotune, ‘

R2G’

is always limited to between 0.1 and 10. If the calculated

value is outside this limit a ‘Tune Fail’ alarm is given.

Loop Break Time ‘

LBT’

Following an autotune, ‘

LBT

’ is set to 2*Ti (assuming the integral time is not set to OFF).

If ‘Ti’ is set to OFF then ‘LBT’ is set to 12*Td.

Auto tune uses the ‘one-shot’ tuner which works by switching the output on and off to induce an oscillation in the

process value. From the amplitude and period of the oscillation, it calculates the tuning parameter values. The autotune

sequence for different conditions is described in sections 11.3.5 to 0.

11.3.4

To Start Autotune

In operator levels 2 or 3, set the ‘AUTO-TUNE ENABLE’ parameter to ‘On’.

Press the Page and Scroll buttons together to return to the Home display. The display will flash ‘

Tune

’ to indicate that

tuning is in progress.

A One-shot Tune can be performed at any time, but normally it is performed only once during the initial commissioning

of the process. However, if the process under control subsequently becomes unstable (because its characteristics have

changed), it may be necessary to tune again for the new conditions.

The auto tune algorithm reacts in different ways depending on the initial conditions of the plant. The explanations given

in this section are for the following conditions:-

1.

Initial PV is below the setpoint and, therefore, approaches the setpoint from below for a heat/cool control loop

2.

Initial PV is below the setpoint and, therefore, approaches the setpoint from below for a heat only control loop

3.

Initial PV is at the same value as the setpoint. That is, within 0.3% of the range of the controller if ‘

PB.UNT

’ is

set to ‘

percent

’ or +1 engineering unit (1 in 1000) if the ‘

PB.UNT

’ is set to ‘

Eng

’. Range is defined as ‘Range

High Limit’ to ‘Range Low Limit’ for process inputs or the range defined in section 8.1 for temperature inputs.

☺

If the PV is just outside the range stated above the autotune will attempt a tune from above or below SP.

☺

If the controller is autotuning and sensor break occurs, the autotune will abort. Autotune must be re-started when

the sensor break condition is no longer present.

☺

If an Autotune cannot be performed an error message,

Etun

, will be flashed in the display

Summary of Contents for XST-2-0-12-1V1-E28

Page 16: ...12 FURNACE TROUBLE SHOOTING ...

Page 27: ...ɸ ...

Page 28: ...ɸ ...

Page 29: ......

Page 30: ......

Page 31: ...3216 3208 3204 User Manual 3200 Range Process Controller HA028651 11 Aug 2012 ...

Page 170: ...User Manual 3200 Series 138 Part No HA028651 Issue 11 0 July 12 21 Certificate of Conformity ...

Page 171: ......

Page 173: ...Model 2416 Process Controller User Manual Part No HA025041_12 Date August 2014 ...

Page 174: ...This page is intentionally blank ...

Page 259: ...This page is intentionally blank ...