6

To switch off the boiler press the ON/OFF bu on ( ). When the boiler is switched off through this

bu on the pump an blockage func on is ac ve, an -frost protec on is not ac ve and there is

electric current in the boiler. In order to switch off the boiler completely, switch the external power

supply fuse-circuit breaker to OFF posi on.

WARNING:

In order an -frost protec on to be ac ve electric and gas supply to the boiler should

not be closed. Observe the requirements indicated in Paragraph 4. When the temperature inside

the boiler drops below 5°C the burner the an -frost protec on switches, turns on the burner and

heats the water up to 30°C.

6 . SWITCHING OFF THE BOILER

In order to use your appliance trouble-free and efficiently for long years we recommend

scheduling annual maintenance, preferably at early winter season, by Thermex authorised

service.

Do not clean external surfaces of your appliance with detergent or chemical materials.

Check your installa on before making connec ons to the boiler and ensure that the installa on

pipes are free from dirt or any par cles.

The life me of wall hung combina on boilers

set by the Ministry of Science, Industry and

Trade is 15 years. According to the relevant

codes the manufacturing companies undertake

to maintain and provide required spare parts of

the appliance during the set life me.

7 . MAINTENANCE OF THE BOILER

8 . INSTALLATION INSTRUCTIONS

Boiler package contains:

Boiler, support Styrofoam, installa on hanging

equipment, user’s manual, warranty cer ficate

and service booklet.

The loca ons where the boiler can be installed

should be selected by observing the relevant

regula ons and requirements set forth by

standards codes of prac ce in force as well as

local gas company standards. Installa on

hanging equipment should be fixed on the wall

in such way to carry the weight of the boiler.

The hanging bracket should be fixed level,

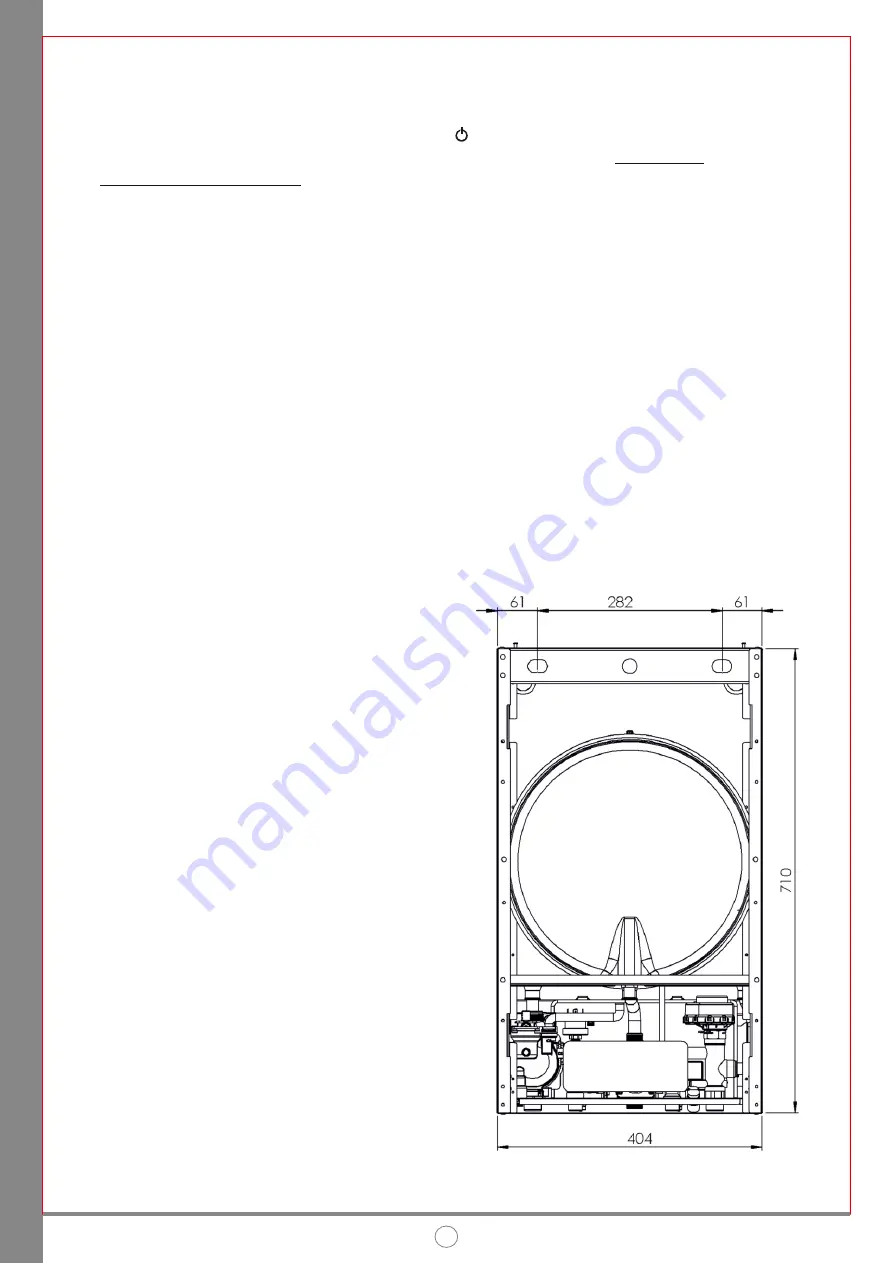

Figure 4.

Figure 4