20

6.4 Maintenance

6.4.1 Spray Head /Parts Maintenance:

1.

Spray Head:

The outer body of the spray head requires occasional cleaning to

eliminate any possibility of metal dust that could cause arc shorting between the

contact tubes. A small stiff brush or knife blade can be used to scrape off the

accumulated metal dust, the head is a plastic material so don’t scrape away head

material. Daily cleaning is recommended, at this frequency all accumulated

material can usually be wiped off with a rag, eliminating the possibility of head

damage.

2.

Contact Tube / Tips

:

During operations the wire will carry dust, dirt, lint,

etc. into the liner system and it will accumulate behind the contact tip in the

contact tube. This can cause enough friction to impair wire feed. Remove the

contact tube from the head, then remove the tip from the contact tube. Clean the

tip manually then use an air blow gun and clean the contact tube. In extremely

dusty conditions this should be done once a day. These items are considered

consumable parts and will require replacement due to wear.

3.

Air Nozzles

:

The air nozzles do not normally require maintenance, except to

keep alignment as shown in the prior sections of this manual. However, if the

nozzles are aligned, and the spray is erratic or uneven, remove the air nozzles and

with an air blow gun clean the holes by reverse blowing through the air jet holes.

Visually inspect the nozzles for obstructions prior to reinstallation.

Summary of Contents for BRIDGEMASTER

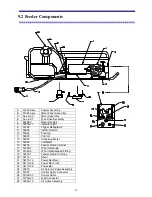

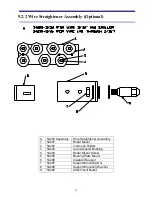

Page 20: ...7 3 System Assembly drawing shows optional straighteners...

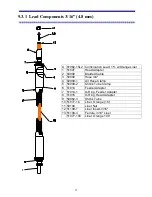

Page 30: ...17 6 2 1 Angle Spray Nozzle 3 16 4 8 mm Wire Head...

Page 31: ...18 6 3 Air Nozzle Alignment 1 8 3 2 mm Wire Head...

Page 32: ...19 6 3 2 Angle Spray Nozzle 1 8 3 2 mm Wire Head...

Page 57: ...44 9 4 1 System Wiring...