45

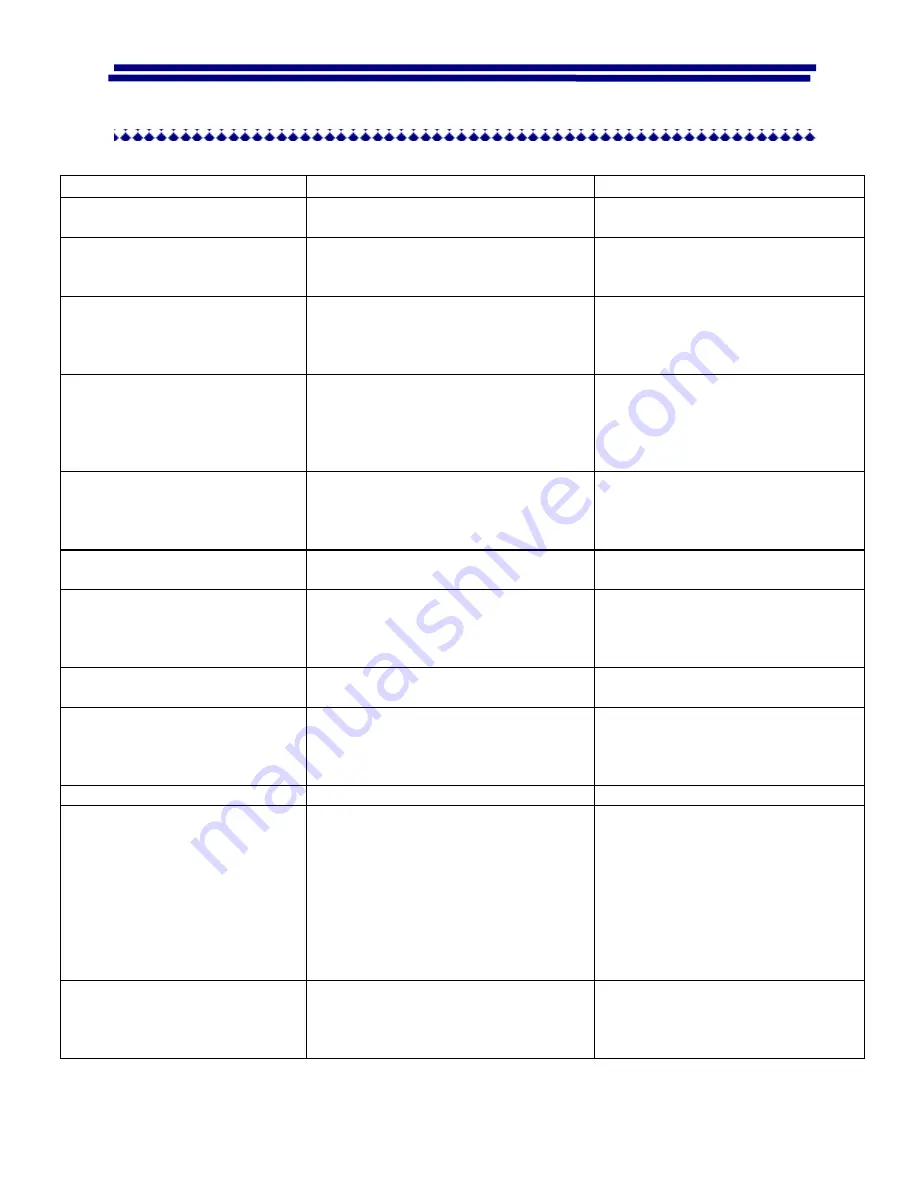

9.5 GENERAL TROUBLESHOOTING

TROUBLE

POSSIBLE CAUSE

REMEDY

No feed, no air, with indicator

light off

1.

No 110 VAC to Feeder

1.

Check Fuse/Breaker on Power

Supply

No wire feed at motor jog sw with

indicator light on, air turns on with

trigger sw

1.

Blown Fuse on Motor Controller

2.

Defective Motor Controller

1.

Replace Fuses.

2.

Replace Motor Controller

No wire feed at motor jog, with

indicator light on, no air with

trigger sw, no air with air sweep

sw

1.

Loose Components Inside Electrical

Box

2.

Defective Relay Control Brd

1.

Inspect For Loose Components

2.

Replace Relay Control Board

Wire feeds with motor Jog Switch,

air turns on with Trigger Switch,

no feed with Trigger Switch

1.

Unconnected Power Cables

2.

Power Supply Defective, Clue! No

Voltage on Volt Meter or Low Open

Circuit Voltage Reading

3.

Loose Relay on Relay Control Brd

1.

Connect Power Cables

2.

Service Power Supply

3.

Inspect For Loose Component

Wire feeds with Motor Jog,

nothing on with Trigger Switch

1.

Defective Trigger SW

2.

Loose or Broken Wire Between

Front Panel and Trigger SW

1.

Replace Trigger SW

2.

Replace Trigger SW and Cord

Assembly or Repair Defective

Part

Spraying begins then stops after a

few minutes

1.

Low Voltage

2.

Dirty Liners

1.

Set Voltage to 29 or higher

2.

Lubricate and Clean Liners

Spray pattern is rough, uneven, or

odd shape

1.

Low Air Pressure

2.

Plugged Air Nozzles

3.

Misaligned Air Nozzles

4.

Defective Air Nozzles

1.

Increase Air to Above 90 PSI

2.

Clean Air Nozzles

3.

Re-align Air Nozzles

4.

Replace Air Nozzles

Wire Feed Motor runs hot

1. Excessive Friction in Liners

1.

Clean and Lubricate Liners More

Frequently

Power Leads heat up

1.

Loose Connections

2.

Oxidized Electrical Connections

3.

Excessive Current

1.

Clean and Tighten All Electrical

Connections

2.

Lower Current Setting to Below

450 Amperes

Wire feeds, cannot get arc

1.

Power Supply Defective

1.

Service Power Supply

Wire feeds, unsteady spray

1.

Loose Electrical Connection

2.

Loose tips

3.

Worn out Feed Rolls, or Loose Rolls

4.

Worn out Feed Roll Gears

5.

Dirty Liners

6.

Worn out Tips, Contact Tube

7.

Head Built Up With Metal Dust

1.

Clean and Tighten All Electrical

Connections

2.

Tighten Tips

3.

Replace (or Tighten) Feed Rolls,

4.

Repair or Replace Feed Roll

Gears

5.

Clean or Replace Liners

6.

Replace Tips & Contact tube

7.

Clean Metal Dust From Head

Air leaks at head

1.

Broken O Ring

2.

Dry O Rings

3.

Liners Too Short

4.

Hole In Liners

1.

Replace O Ring

2.

Lubricate O Rings

3.

Replace Liner

4.

Replace Liner

Summary of Contents for BRIDGEMASTER

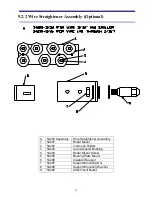

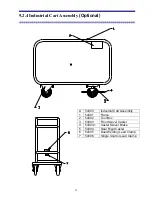

Page 20: ...7 3 System Assembly drawing shows optional straighteners...

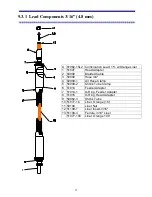

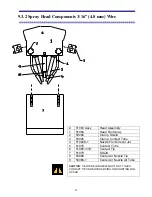

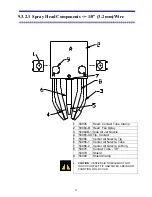

Page 30: ...17 6 2 1 Angle Spray Nozzle 3 16 4 8 mm Wire Head...

Page 31: ...18 6 3 Air Nozzle Alignment 1 8 3 2 mm Wire Head...

Page 32: ...19 6 3 2 Angle Spray Nozzle 1 8 3 2 mm Wire Head...

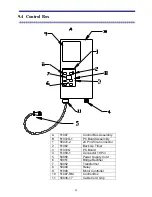

Page 57: ...44 9 4 1 System Wiring...