BTH Electric Boilers

USE & CARE MANUAL

(Revision August /06)

, Page

19.

B T H

9

5

1

2

4

3

11

12

14

13

6

7

8

10

15

16

TYP: 85°F

TYP.:150°F

17

18

20

19

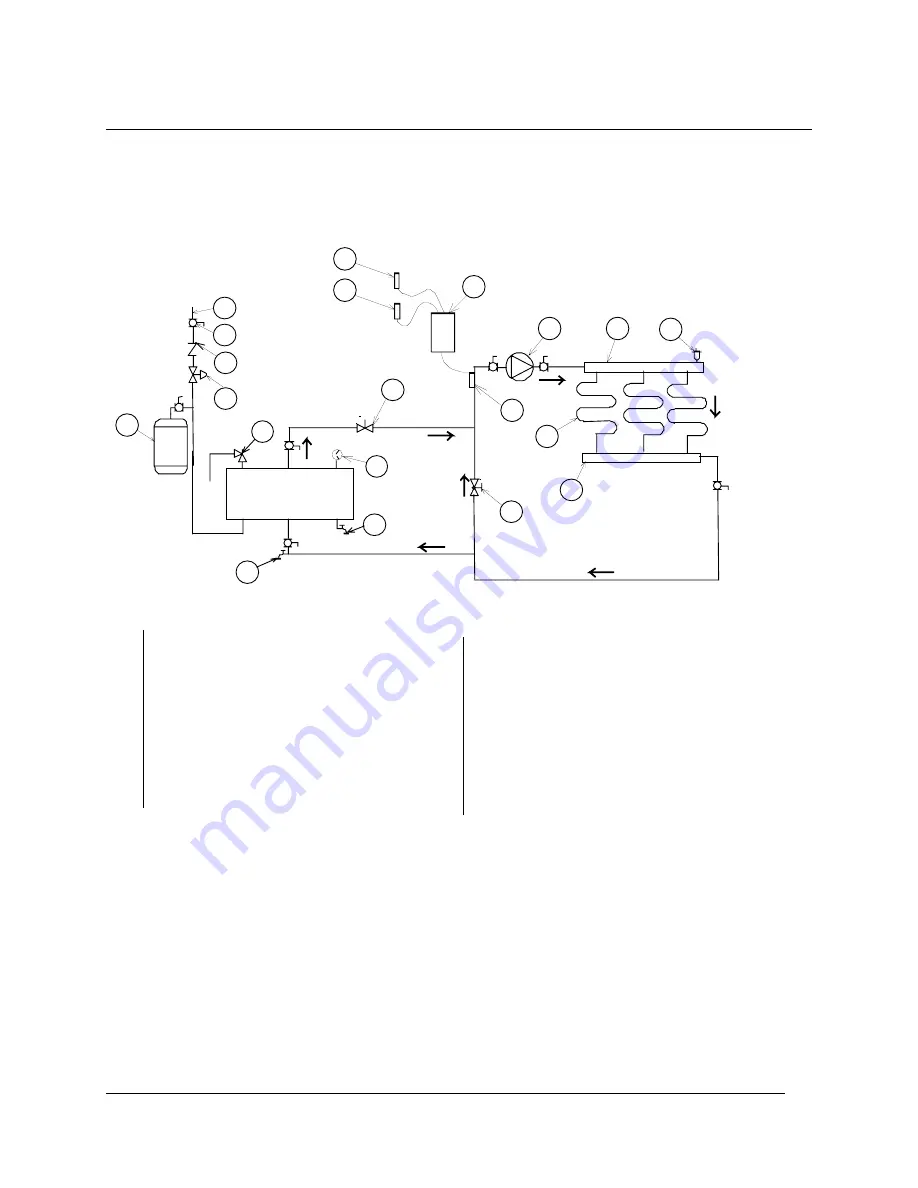

SYSTEM PIPING LAYOUT:/

SCHÉMA D'INSTALLATION GENERAL

MODULATING BOILER WATER SUPPLY TO RADIANT HEATING LOOP/

PLANCHER CHAUFFANT MODULANT

11-AUTOMATIC AIR VENT/ PURGEUR D'AIR

12-SUPPLY HEADER/ COLLECTEUR D'ALIMENTATION

14-RADIANT IN-FLOOR PIPING/ PLANCHER CHAUFFANT

13-RETURN HEADER/ COLLECTEUR DE RETOUR

1- MAIN WATER SUPPLY/ ALIMENTATION D'EAU

2-MAINTENANCE VALVE/ VALVE D'ENTRETIEN

3-CHECK VALVE/ CLAPET ANTI-GRAVITÉ

4-PRESSURE REDUCER/ RÉDUCTEUR DE PRESSION

5-EXPANSION TANK/ RÉSERVOIR DE DILATATION

6-CIRCULATING PUMP/ POMPE RECIRCULATION

8-DRAIN VALVE/ VALVE DE DRAINAGE

9-SAFETY VALVE/ SOUPAPE DE SÛRETÉ

7-PURGE VALVE/ ROBINET D'ÉLIMINATION D'AIR

10-TEMPERATURE AND PRESSURE GAUGE/

THERMOMANOMÈTRE

LEGEND :

15-INJECTION VALVE (SLOW OPENNING)/

VALVE D'INJECTION

16-CIRCUIT BALANCING VALVE/ VALVE DE BALANCEMENT

18-BOILER WATER SUPPLY TEMP. SENSOR/

SONDE DE TEMPÉRATURE D'EAU

19-EXTERIOR TEMPERATURE SENSOR/ SONDE TEMP. EXT.

17-INDOOR / OUTDOUR CONTROLLER/

CONTRÔLEUR MODULANT INT.-EXT.

20-AMBIANT TEMPERATURE SENSOR/ SONDE TEMP. AMBIANTE

Requirements:

1. The installation must conform to local, state, provincial, national codes. In any case where instructions conflict with the

above, let those codes take precedence.

2. This is a basic piping schematic. Please consult the installation manual.

3. Install a pressure relief valve (safety relief valve) on the boiler.

4. Pipe all the safety relief valves and drain valves to the drain or according to the code.