DTH Electric Boilers USE & CARE MANUAL

(Revision June 2014)

, Page

6.

Section 3 : INSTALLATION

The manufacturer’s warranty does not cover

any damage or defect caused by installation,

or attachment, or use of any special

attachment other than those authorized by

the manufacturer, into, onto, or in

conjunction with the boiler. The use of such

unauthorized devices may shorten the life of

the boiler and may endanger life and

property. The manufacturer disclaims any

responsibility for such loss or injury

resulting from the use of such unauthorized

devices

3.1 SECURITY CONSIDERATIONS

Domestic and commercial installations have a

maximum design operating pressure limited to

30 psi (207 kPa) or 60psi (414kPa) by a safety

relief valve.

Boiler maximum operating temperature is 190°F

by design. This boiler is designed to be used

only in a hot water heating system.

The heat transfer medium must be water or

other non-toxic fluid. An antifreeze solution

with propylene glycol specially formulated

for heating system could be used up to a

maximum concentration of 50%

3.2 LOCATION

The electric boiler should be installed in a clean,

dry location. Long hot water lines should be

insulated to conserve energy. The electric boiler

and water lines should be protected from

exposure to freezing temperatures.

The electric boiler must be installed horizontally

directly on the floor or wall. Supporting legs are

included but wall mounting brackets are not.

The electric boiler must be located or protected

so as not to be subject to physical damage, for

example, by moving vehicles, area flooding, etc.

All models can be installed on combustible floors

and in alcoves. Ambient temperature must not

exceed 80°F or 27°C.

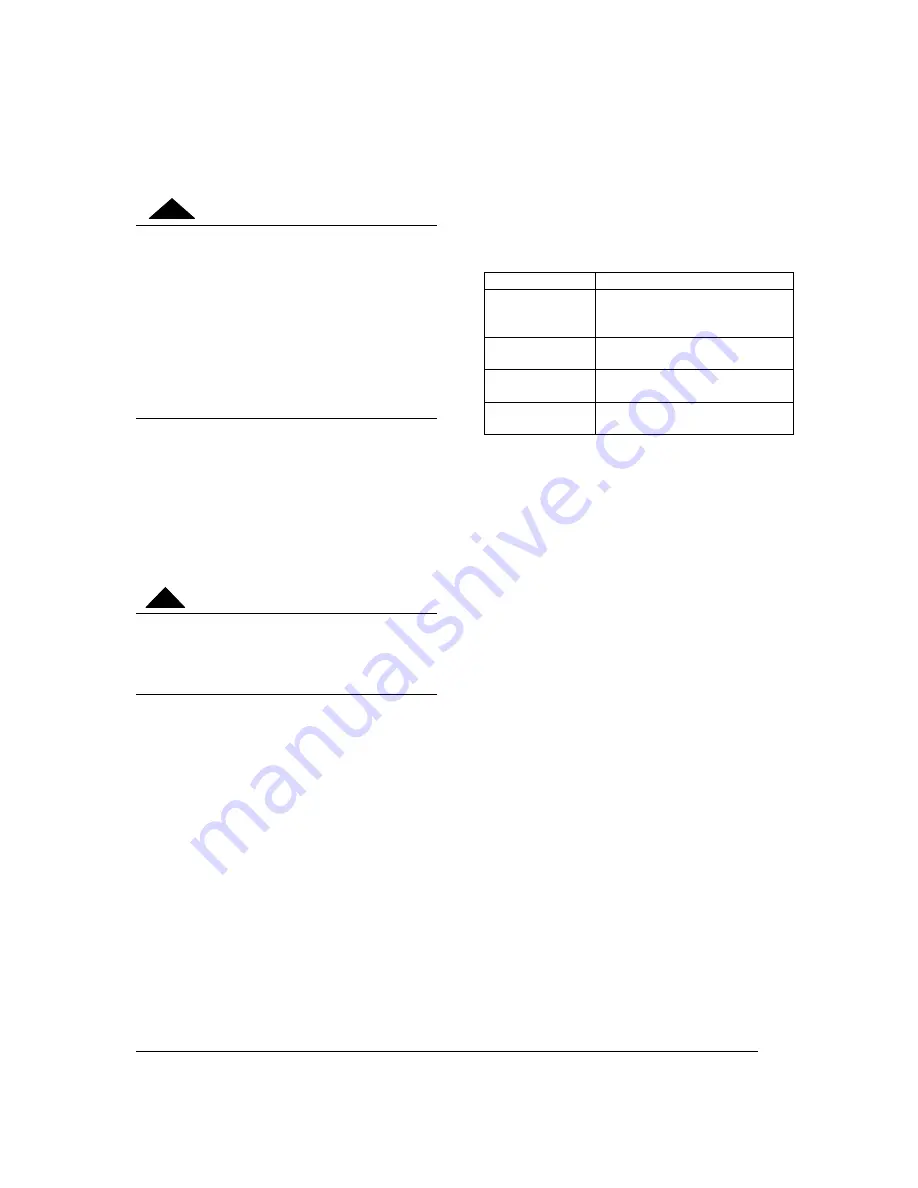

3.3 CLEARANCE

Minimum clearances for adequate inspection

and servicing are listed in the following table:

Table 4: Boiler clearance

Left side

14 inches

Right side

14 in.(78to144kW 480&600v)

(54to96kWx 240v)

0in. Other models

Top & bottom of

the boiler

12 inches

Front side of the

boiler

24 inches

Back side of the

boiler

0 inch

3.4 SYSTEM SETUP

The recommended piping arrangement is shown

in Figure 4, 5 and 6 including the pump,

expansion tank, drain valve, pressure relief

valve, air vent, flow check valve and pressure-

temperature gauge. Details about each item

follow.

3.4.1 Boiler connections

This electric boiler may be connected

individually or in parallel with other boilers. If two

or more boilers are connected, the “reverse-

return piping” method (whereby the boiler with

the first return inlet also has the last supply

outlet and so forth until the last return inlet

corresponds to the first supply outlet) should be

used to connect the boilers in parallel, to ensure

an equal water flow rate through each boiler.

The boiler water supply, located on the top side,

and the boiler water return, located on the

bottom side of the boiler are steel pipes (male

NPT threaded connection) where supply and

return line connections are to be made.

Installing a union is recommended on the boiler

water supply and return lines to facilitate boiler

disconnection for servicing.

Dielectric unions are required for protection of

the boiler and piping if dissimilar pipe material

such as galvanized steel and copper are

present.

WARNING

!

CAUTION

!