DTH Electric Boilers USE & CARE MANUAL

(Revision June 2014)

, Page

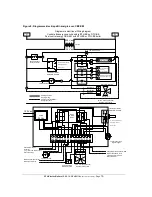

7.

Use only clean, new piping for boiler water lines.

Local codes or regulations shall govern the

exact type of material to be used.

Insulate all pipes containing hot water,

especially in unheated areas.

Install shutoff (ball) valves for servicing

convenience. Thermometer(s) should be

installed on the boiler water supply and return

lines.

Cap or plug unused connections on the boiler.

Do not cap the pressure relief valve on the

boiler since it will damage and shorten the life of

the boiler and may endanger life and property.

3.4.2 Flow check valve

If the heating system includes a single pump,

then to minimize flow by gravity and heat loss

during non-draw periods, a flow check valve

must be installed.

3.4.3 Pressure relief valve

An automatic pressure relief valve must be

installed during boiler setup. The pressure

rating of the relief valve must not exceed the

pressure design of the boiler as shown on the

pressure vessel name plate. The safety relief

valve must meet the requirements of the ASME

Boiler and Pressure Vessel Code and limit the

maximum operating boiler pressure. It is a

safety device, not an operating control.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as marked on the

boiler(s) rating plate.

Connect the outlet of the relief valve to a

discharge line with its lower tip at most 6” above

a floor drain, well clear of any live electrical

parts. The discharge line must pitch downward

from the valve to allow complete draining by

gravity of the relief valve and discharge line, and

be of a diameter no smaller than that of the

valve outlet. The tip of the discharge line should

not be threaded or concealed and should be

protected from freezing. No valve of any type,

restriction or reducer coupling should be

installed on the discharge line. Local codes

shall govern the installation of relief valves.

3.4.4 System pressure control and

expansion tank

Pressure control devices within the system

ensure that each component operates within

minimum and maximum allowable pressures

and maintain minimum pressure for all normal

operating temperatures. They also allow air

bleeding, prevent cavitation at the pump inlet

and prevent water from boiling within the

system; all this is accomplished with minimal

addition of new water.

The increase in boiler water volume resulting

from higher temperature is stored in the

expansion tank during periods of high operating

temperature and is returned to the system when

the temperature decreases.

The expansion tank must be able to store the

required volume of boiler water during maximum

design operating temperature without exceeding

the maximum allowable operating pressure, and

to maintain the required minimum pressure

when the system is cold. Contact your installing

contractor, plumbing supply house, or local

plumbing inspector for assistance.

The point where the expansion tank is

connected should be carefully selected to avoid

the possibility that normal operation of automatic

check or manual valves will isolate the tank from

a hot boiler or any part of the system. Pre-

charged diaphragm expansion tanks are

preferable to air control (see section 3.4.6).

These tanks incorporate a balloon-like bladder

or diaphragm. It is inflated, prior to filling the

system, to a pressure equal to the setting of the

water pressure makeup regulator.

The expansion tank should be located on the

suction or intake side of the pump. The pump

can be located either just upstream or just

downstream from the boiler.

3.4.5 Water pressure makeup regulator

Make-up systems must be employed as

required by codes. An automatic fill valve

must be used with a backflow preventer as

required, to maintain minimum system pressure

by supplying water to make up for leakage.

3.4.6 Air bleeder

Oxygen should be excluded from the system to

prevent corrosion. As hinted at in section 3.4.4,

this precludes the use of air in direct contact with

the boiler water as a pressurization means.

Installation of manual or automatic air vent

devices prevents air from accumulating in the

system. Air vents should be installed at all high

points to remove trapped air during initial setup

and to ensure that the system is tight. Regularly

purge the air out of the system while taking care

to avoid personal injuries or property damage

caused by hot boiler water spray.