10

Specifications

Model - OTF - ITF

510

801

1010

1600

Gross Input

140,000

210,000

280,000

350,000

Gross Output - BTU/Hr.

109,200

163,800

218,400

273,000

Flue Pipe Dia.

6"

6"

8"

8”

Firing Rate - GPH

1.00

1.50

2.00

2.50

Width OTF-ITF

22"

22"

26-1/4"

26-1/4"

Length OTF-ITF

31"

31"

34"

34"

Height OTF-ITF

38-1/2"

38-1/2"

45"

45"

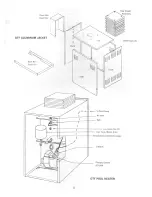

STANDARD EQUIPMENT

OTF

—

Al

umi

num

j

ac

k

et

wi

t

h

s

el

f

v

ent

i

ng

/

I

TF

-

Fl

us

h

J

ac

k

et

wi

t

h

Bak

ed

Enamel

Fi

ni

s

h

Boiler body with combustion chamber installed, theraltimeter, completely assembled and packaged with oil burner,

cadcell relay, pool & limit control, low water cutoff (OTF only), relief valve, indirect pool heating coil SC-150 (510/801)

SC-200 (1010/1600) with 1-1/2" I.P.S. tappings.

Selection of the right size OTF/ITF Heater

There are many factors related to proper sizing of Pool Heaters. We recommend you contact your installing dealer for

help in determining the correct size for your particular application.

POOL HEATER SIZING CHART - HEAT LOSS FROM POOL SURFACE - BTUs PER HOUR

Desired

PoolTemperature

(°F)

Surface Area of Pool

Sq. Ft.

80°

85°

90°

Approximate

Gallons

500

137,000 Btu.

155,000 Btu.

200,000 Btu.

20,000

600

166,000 Btu.

185,000 Btu.

240,000 Btu.

24,000

700

200,000 Btu.

218,000 Btu.

280,000 Btu.

28,000

800

220,000 Btu.

250,000 Btu.

320,000 Btu.

32,000

900

248,000 Btu.

280,000 Btu.

360,000 Btu.

36,000

1000

275,000 Btu.

310,000 Btu.

400,000 Btu.

40,000

1200

330,000 Btu.

370,000 Btu.

480,000 Btu.

48,000

1400

384,000 Btu.

435,000 Btu.

560,000 Btu.

56,000

1600 or Larger: Refer inquiry to Thermo-Dynamics, Schuylkill Haven, PA 17972

NOTES: 1. These heat losses are based on an assumed wind velocity at the water surface of 5 m.p.h. and an ambient

temperature of 60°F.

2. Where surface area and gallons do not coincide, surface area must take precedence.