BUS Operation and Maintenance

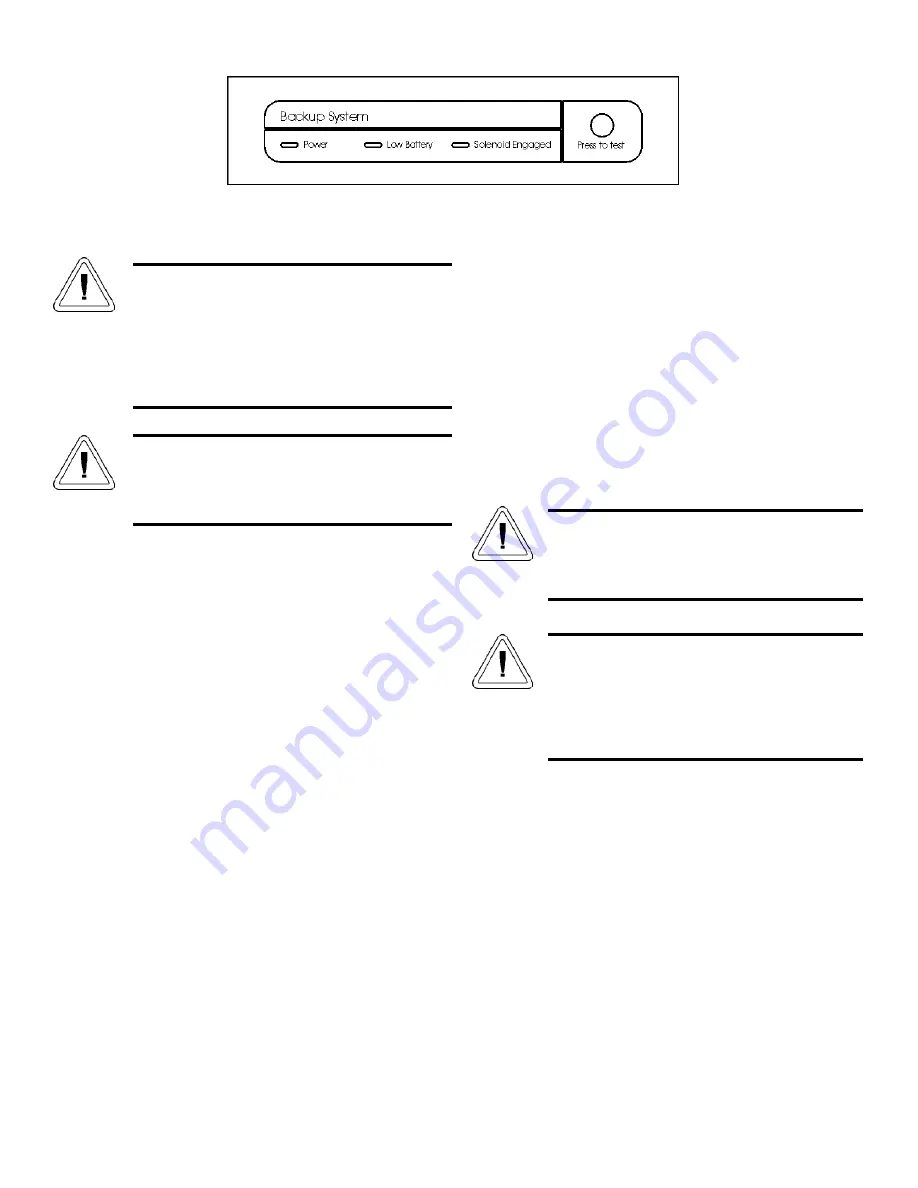

d. BUS Control Panel (see figure 5-6)

Power

- indicates the unit has AC power.

Low Battery

- battery charge is low. The battery needs replaced

or recharged.

Solenoid Engaged

- BUS has opened the solenoid so it can inject

gas (CO

2

or LN

2

).

Press-To-Test

- Activates the solenoid and injects LN

2

or CO

2

into the freezer chamber as long as the button is depressed. The

solenoid engaged indicator should light. If the Low Battery indi-

cator lights during the test, replace the BUS battery.

Note: sole-

noid will not engage if door is open.

e. Configuring the Optional BUS (Back Up System)

The optional BUS can be configured for LN

2

or CO

2

supply.

To select the supply type:

1. Press the Mode key until the Backup indicator lights.

2. Press the up or down arrow key. The display will show

OP1 for CO

2

selection and OP2 for LN

2

selection.

3. Press Enter to save the setting.

4. Press the Mode key until the Run indicator lights for Run

mode

If no control keys are pressed, the freezer will automatically

return to to RUN mode after 5 minutes.

f. Setting the Optional BUS Set Point

The optional back up system is designed to inject CO

2

or

LN

2

into the freezer compartment if the temperature rises above

back up system set point. To set the BUS set point:

1. Press the Mode key until the Set Temperature and Backup

indicators light.

2. Press the up or down arrow key until the desired BUS set

point is displayed.

3. Press Enter to save the setting.

4. Press the Mode key until the Run indicator lights for Run

mode

If no control keys are pressed, the freezer will automatically

return to to RUN mode after 5 minutes.

g. Cleaning the Vent Stack

Routinely check the vent stack for frost or ice build-up. The

type of frost that forms in the vent stack is generally very soft

and may be easily removed with a bristle brush or soft cloth. if

ice build-up has occurred, a complete defrost may occasionally

be required. See section 4.4 for freezer defrost instructions.

h. Disconnecting the Fitting Assembly and

Transfer Hose

To disconnect the freezer back-up from the gas supply:

1. Close the supply valve.

2. Depress the test button on the BUS control box to remove

the gas from the line.

3. Slowly disconnect the fitting assembly from the supply (in

the event that any gas remains in the line).

Model 900 Series ____________________________________________________________________Factory Options

5 - 3

WARNING! When activated, this unit injects liq-

uid nitrogen or carbon dioxide. Liquid Nitrogen

can cause serious freezing (frostbite) if it comes in

contact with unprotected skin or eyes. Nitrogen

suppresses oxygen levels and may cause suffoca-

tion if area is not well ventilated. Refer to

Appendix A for the proper handling of liquid LN

2

.

Carbon Dioxide gas suppresses oxygen levels and

may cause suffocation if area is not well ventilat-

ed. Refer to “Handling Liquid CO

2

in Appendix B

of this manual.

Figure 5-6

The BUS set point can not be set any colder than

the high temperature alarm set point. (See section

1.6.b). If the back-up system is installed with CO

2

,

then -65°C is the coldest BUS set point that can

be used (if the cabinet set point is -75°C or

colder).

Changing the operating temperature set point can

affect the BUS set point. The BUS set point will

self adjust to maintain a temperature of at least

10°C above the operating temperature set point.

Summary of Contents for 900 Series

Page 1: ...900 Series Forma 86C ULT Freezer Operating and Maintenance Manual Manual No 7010902 Rev 8 ...

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......