Service Instructions Safety Cabinet HERAsafe KS / KSP

Service Instructions Safety Cabinet HERAsafe KS / KSP

24

24

4

4

.

.

M

M

e

e

d

d

i

i

a

a

c

c

o

o

n

n

n

n

e

e

c

c

t

t

i

i

o

o

n

n

s

s

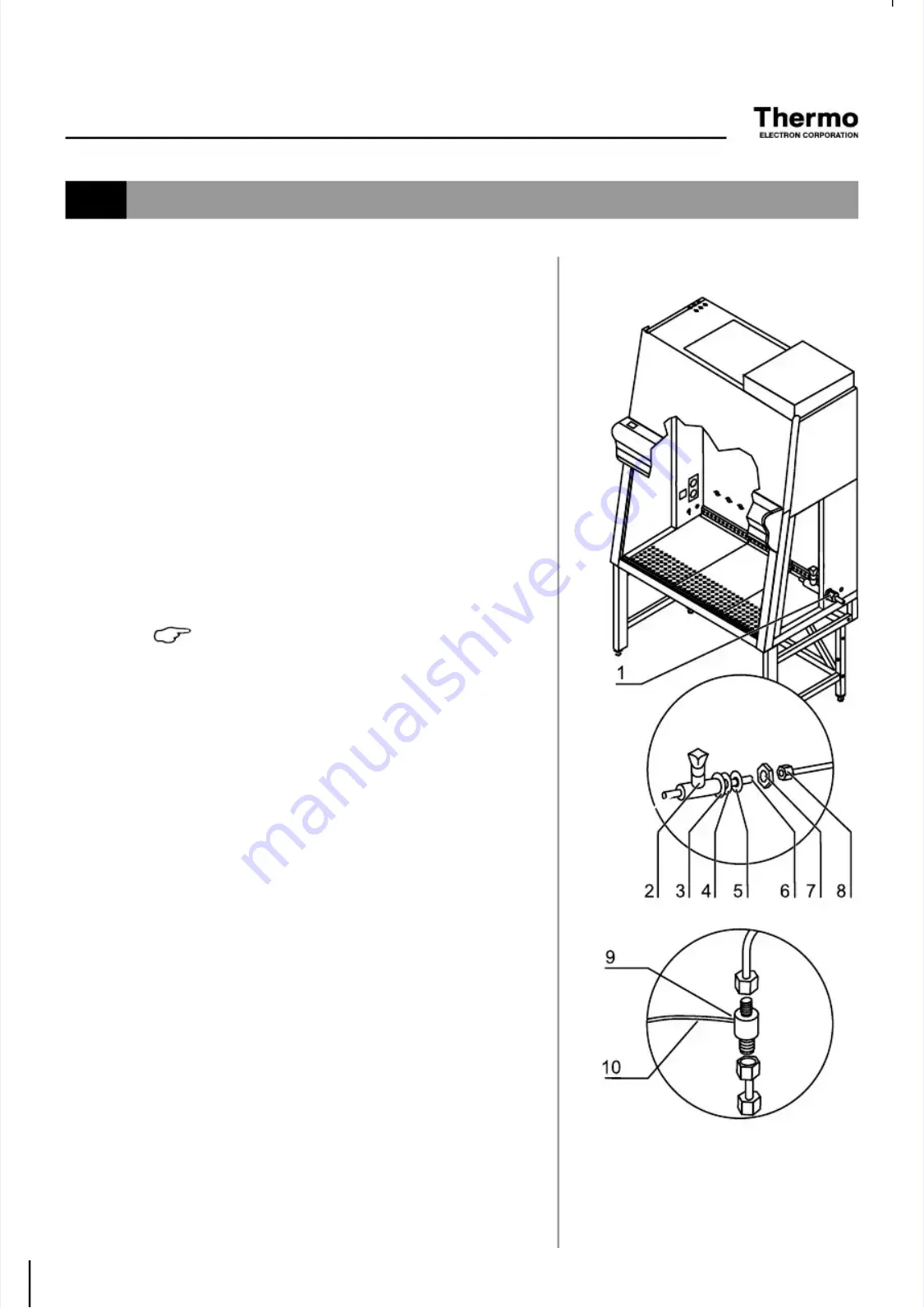

Installing media valves to the sidewall:

Installing media valves to the sidewall:

Fig. 8:

Fig. 8:

The media valves are installed to the preinstalled lead-

The media valves are installed to the preinstalled lead-

ins [1].

ins [1].

1.

1. Move the

Move the front wi

front window to t

ndow to the maxi

he maximal open

mal opening posit

ing position.

ion.

2.

2. Switch

Switch the devic

the device off, di

e off, disconnect

sconnect it from

it from the power s

the power supp-

upp-

ly system, and protect it from accidental reconnection.

ly system, and protect it from accidental reconnection.

3.

3. Remove

Remove the plug

the plug from th

from the sidewa

e sidewall lead-

ll lead-in or rem

in or remove the

ove the

plug and disconnect the PG screw connection.

plug and disconnect the PG screw connection.

4.

4. Slid

Slide the gask

e the gasket [4] an

et [4] and the beze

d the bezel [3] ont

l [3] onto the thre

o the threaded pi

aded pipe

pe

of the media valve [2].

of the media valve [2].

5.

5. From t

From the inside

he inside of the sa

of the sample cham

mple chamber,

ber, push the

push the media

media

valve through the lead-in.

valve through the lead-in.

6.

6. From th

From the outsi

e outside, slid

de, slide the other gas

e the other gasket [5] onto th

ket [5] onto the threa-

e threa-

ded pipe of the media valve.

ded pipe of the media valve.

7.

7. Secur

Secure the medi

e the media valve to t

a valve to the side

he sidewall le

wall lead-in us

ad-in using the nu

ing the nutt

[7].

[7].

8.

8. Connect

Connect the mead

the meadia supply

ia supply line usi

line using a unio

ng a union nut [8].

n nut [8].

NOTE - Combustible gas

NOTE - Combustible gas

If combustible gas is to be supplied into the

If combustible gas is to be supplied into the

sample chamber, the media valve solenoid

sample chamber, the media valve solenoid

must be integral to the device

must be integral to the device control. The gas

control. The gas

supply is controlled in a way that the gas sup-

supply is controlled in a way that the gas sup-

ply is activated when the

ply is activated when the device is operational.

device is operational.

The annex of these service instructions con-

The annex of these service instructions con-

tains wiring diagrams for integrating the sole-

tains wiring diagrams for integrating the sole-

noid into the device control.

noid into the device control.

Installing the solenoid:

Installing the solenoid:

The solenoid is installed externally, either to the

The solenoid is installed externally, either to the sidewall supply

sidewall supply

line or to the supply lines at the device ceiling.

line or to the supply lines at the device ceiling.

1.

1. Instal

Install the

l the solenoid

solenoid [9] int

[9] into the s

o the supply

upply line.

line.

2.

2. Connnec

Connnect the con

t the connecting

necting cables

cables [10] to th

[10] to the devic

e device control

e control

(see wiring diagrams in the annex).

(see wiring diagrams in the annex).

Fig. 8,

Fig. 8,

UV connection

UV connection

Installing media valves to the

Installing media valves to the

sidewall

sidewall

Summary of Contents for HERAsafe KS

Page 118: ...117 117 ...