61

SPECTRUM™ TS Operation

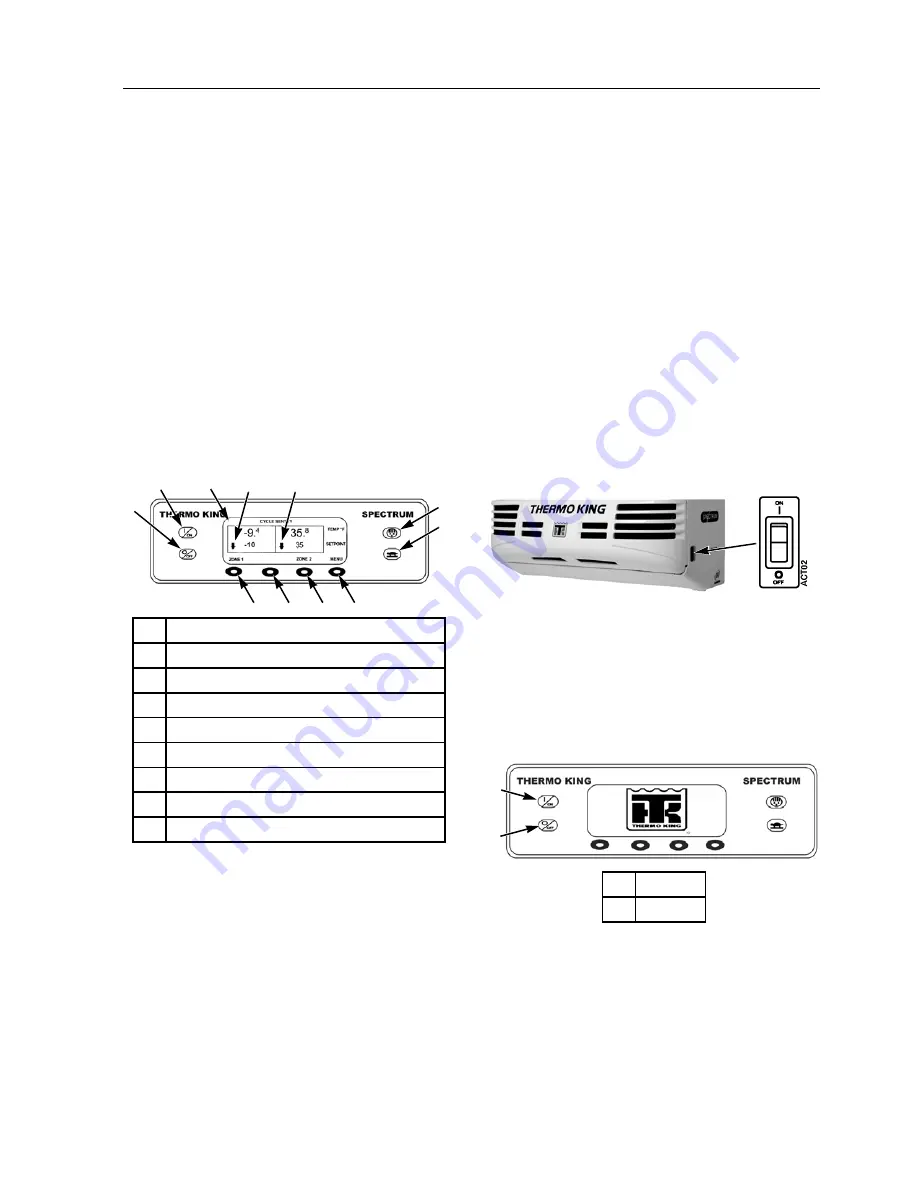

HMI Controller Overview

The HMI (Human Machine Interface) Control

Panel is connected to the microprocessor and is

used to operate the unit. It is located in the truck

cab mounted in or under the dashboard.

The HMI control panel consists of a display and 8

touch sensitive keys. The display is capable of

showing both text and graphics. The four keys on

the left and right sides of the display are dedicated

keys and the functions are described in detail later

in this chapter. The four keys under the display

are “soft” keys. The function of “soft” keys

change depending on the operation being

performed. If a soft key is active, the current key

function will be shown in the display directly

above the key.

Display

The display is used to supply unit information to

the operator. This information includes setpoint

and temperature for all installed zones, zone

operating information, unit gauge readings,

system temperatures and other information as

selected by the operator.

The Standard Display of box temperature and

setpoint for 2 zones is shown here. In the display

shown here, Zone 1 has a setpoint of -10 F and a

box temperature of -9.4 F. Zone 2 has a setpoint

of 35 F and a box temperature of 35.8 F

Microprocessor Power Switch

The Microprocessor Power switch applies 12 Vdc

power to the microprocessor. The switch must be

in the “On” position to operate the

microprocessor. It is located on the unit frame on

the road side of the unit.

NOTE: When the Microprocessor Power Switch

is turned to the Off position, power is still applied

to the Interface Board and the HMI. To

completely remove power from the control

system, disconnect the unit battery.

Figure 37: Microprocessor Power Switch

Turning the Unit On and Off

The unit is turned on by pressing the

O

N

key and

off by pressing the

O

FF

key. When the On key is

pressed the display will briefly show THERMO

KING as the display initializes.

Then the startup screen shown below appears

while communications are established and the unit

prepares for operation. See Figure 39 on page 62.

1.

On Key (Dedicated Key)

2.

Off Key (Dedicated Key)

3.

Display

4.

Defrost Key (Dedicated Key)

5.

High Speed Lockout Key (Dedicated Key)

6.

Soft Keys

7.

Arrow Up- Zone is Heating

8.

Arrow Down - Zone is Cooling

No Arrow - Zone is in Null

Figure 36: Dedicated and soft keys

AJA1112

6

5

4

2

3

8

1

6

6

6

7

1.

On Key

2.

Off Key

Figure 38: On/Off Key

AJA1167

AJA1107

1

2

Summary of Contents for SPECTRUM TS 30 SR NAD

Page 4: ...4 ...

Page 10: ...Table of Contents 10 ...

Page 20: ...Safety Precautions 20 ...

Page 51: ...Unit Description 51 Figure 19 Front View Figure 20 Back View AJA1350 AJA1500 ...

Page 52: ...Unit Description 52 1 On Off Switch Figure 21 Side View 1 ...

Page 60: ...Unit Description 60 ...

Page 80: ...SPECTRUM TS Operation 80 ...

Page 90: ...Electrical Maintenance 90 ...

Page 100: ...Engine Maintenance 100 Figure 130 Early TK 3 95 Fuel and Oil System Components ...

Page 102: ...Engine Maintenance 102 Figure 131 Late TK 3 95 Fuel and Oil System Components ...

Page 104: ...Engine Maintenance 104 Figure 132 TK376 Fuel and Oil System Components ...

Page 136: ...Refrigeration Maintenance 136 ...

Page 156: ...Hilliard Clutch Maintenance 156 ...

Page 158: ...Structural Maintenance 158 ...

Page 168: ...Remote Evaporator Specifications 168 ...

Page 170: ...Remote Evaporator Maintenance Inspection Schedule 170 ...

Page 176: ...Remote Evaporator Electrical Maintenance 176 ...

Page 180: ...Remote Evaporator Refrigeration Service Operations 180 ...

Page 182: ...Remote Evaporator Structural Maintenance 182 ...

Page 184: ...Remote Evaporator System Diagnosis 184 ...

Page 188: ...Wiring and Schematic Diagrams Index 188 ...

Page 189: ...189 Wiring Diagram Page 1 of 4 ...

Page 190: ...190 Wiring Diagram Page 2 of 4 ...

Page 191: ...191 Wiring Diagram Page 3 of 4 ...

Page 192: ...192 Wiring Diagram Page 4 of 4 ...

Page 193: ...193 Schematic Diagram Page 1 of 3 ...

Page 194: ...194 Schematic Diagram Page 2 of 3 ...

Page 195: ...195 Schematic Diagram Page 3 of 3 ...

Page 196: ...196 ...