All installations and services must be performed by qualified service personnel.

27

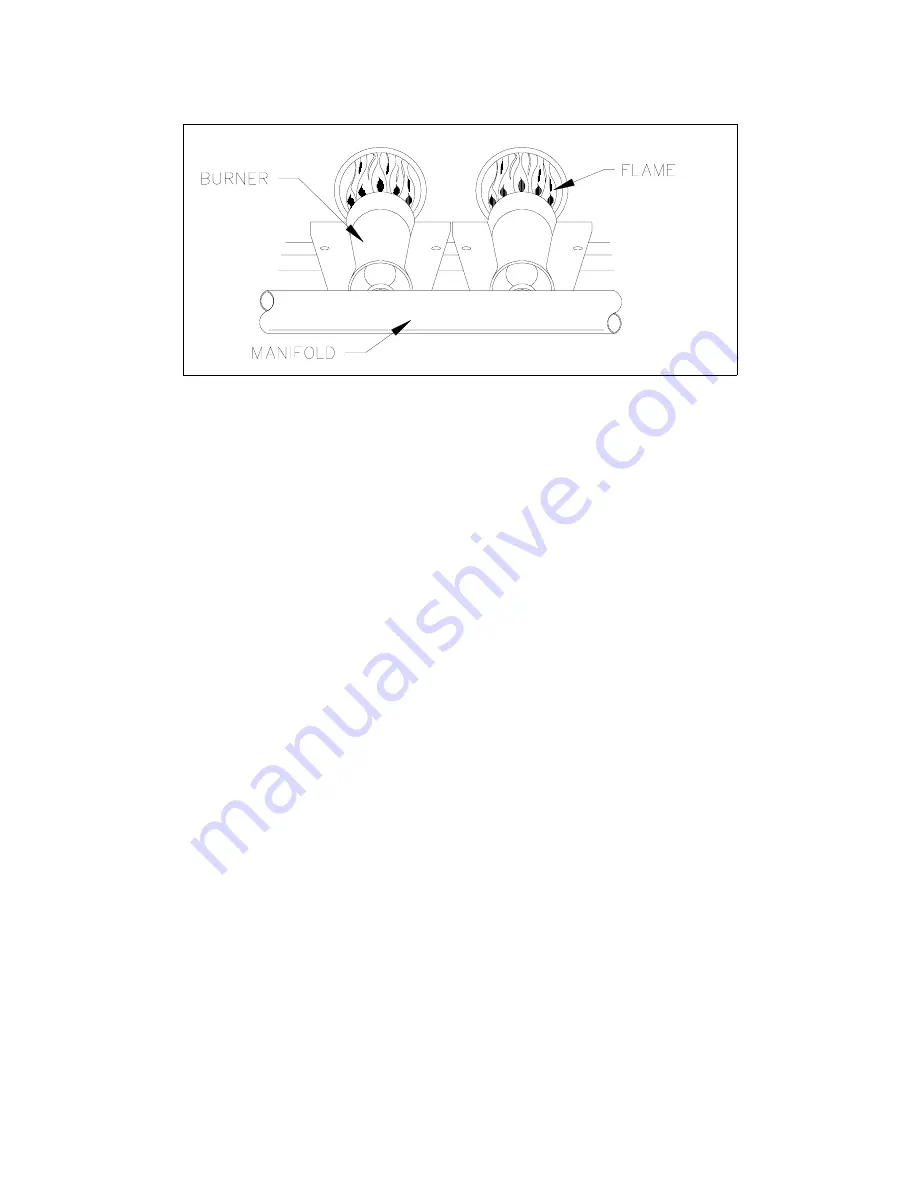

Figure 9

N. SETTING TEMPERATURE RISE

The GMD1-80N is designed and wired at the factory for a heating blower speed that

should result in an approximate temperature rise of 70

°

F. The blower motor is wired on

medium low speed for heating mode. The temperature rise through the furnace may

vary depending on the duct system, elevation, heating value, etc. for each installation.

After 10 to 15 minutes of continuous operation, the temperature rise through the

furnace must fall within a range of 55

°

F to 85

°

F. If the outlet or supply duct

temperature is too high, check to make sure the return air filter is clean, the return air

registers are free from obstruction, the outlet registers are properly adjusted and clear,

and the supply and return air ducts are open.

The circulating air blower is not moving enough air if the supply air temperature is still

too high. Before proceeding further, turn off the power supply to the furnace and

remove the blower door. The speed of the blower must be increased by changing the

speed tap from the motor (see wiring diagram). This is accomplished by locating the

control panel attached to the blower housing and switching blue (med. low) blower lead,

which should be connected to the “Heat” terminal on the White-Rodgers 50A65-143

control, with one of the higher speed blower leads attached to a terminal marked “Park”.

Be sure to attach any unused blower leads to a terminal marked “Park”. Replace the

blower door and turn on the power supply.

O. FURNACE CHECKOUT PROCEDURE

Before any system of gas piping is finally put into service, it shall be carefully tested to

assure that it is gas tight as indicated in section IV. H. Gas Piping of this manual.