All installations and services must be performed by qualified service personnel.

24

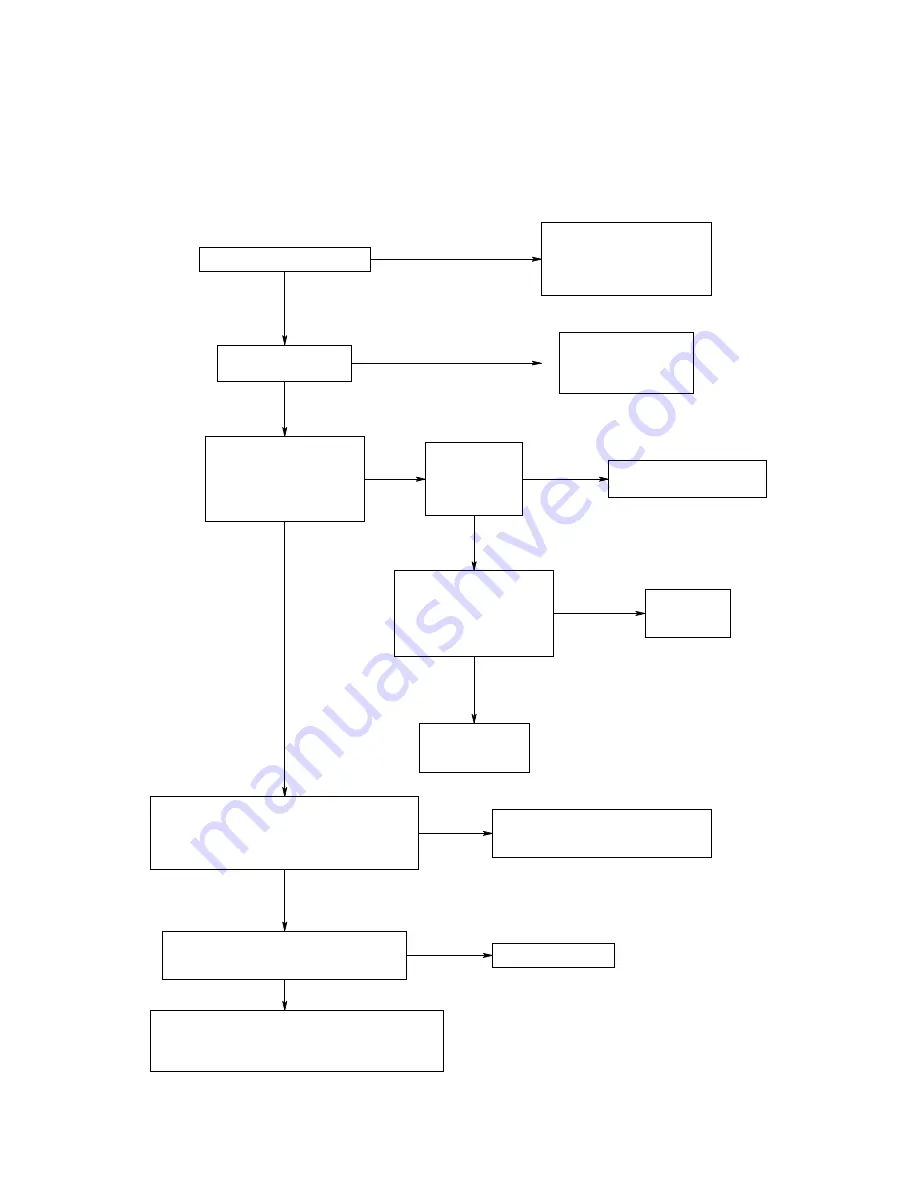

CONFIRM IF EITHER BLOWER

WHEEL IS RUBBING AGAINST

HOUSING OR MOTOR SHAFT

IS SPINNING FREELY, REPAIR

OR REPLACE AS NECESSARY.

DOES BLOWER SPIN FREELY?

IS THERE 115V

SUPPLIED TO MOTOR?

CHECK 115V SUPPLY,

CONNECTION FUSES,

SERVICE SWITCH AND

DOOR SWITCH.

CHECK HARNESS

CONNECTIONS

AND WIRE.

NO

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

THIS GUIDE SHOULD BE USED IN THE CASE OF A STOPPED OR MANFUNCTIONED ECM

BLOWER MOTOR. THE FOLLOWING SHOULD HELP ESTABLISH THE TYPE OF

MALFUNCTION OR DEVIATION FROM THE NORMAL BLOWER OPERATION.

TO USE THIS DIAGRAM, YOU JUST NEED TO FOLLOW THE INSTRUCTIONS IN THE BOXES.

CHECK 24V SUPPLY

TO INTEGRATED CONTROL.

IS THERE 24V

ACROSS R &

B/C ON THE

INTEGRATED

CONTROL?

REPLACE

INTEGRATED

CONTROL.

CHECK CONNECTIONS AND WIRES

AT INTEGRATED CONTROL, IF OK

REPLACE INTEGRATED CONTROL.

CHECK CONNECTION ON HARNESS AND MOTOR,

RECONNECT HARNESS TO MOTOR, IF

CONNECTIONS ARE GOOD AND MOTOR STILL

DOES NOT RUN REPLACE MOTOR.

REPLACE 16x4 BOX

NO

NO

YES

DISCONNECT 4 PIN COMMUNICATION

HARNESS FROM MOTOR.

IS THERE 30-35 VDC ACROSS PIN 1 & 4?

DISCONNECT 16 PIN

HARNESS FROM

16x4 BOX. IS THERE 12VDC

ACROSS PIN12 & PIN1

AND PIN12 & PIN3

AT THE HARNESS PLUG?

DISCONNECT 16PIN

HARNESS FROM

INTEGRATED CONTROL.

IS THERE 12VDC ACROSS

PIN6 & PIN1

AT THE CONTROL?

TURN THERMOSTAT MANUAL FAN

SWITCH ON (IF AVAILABLE) OR JUMPER

BETWEEN R & G ON INTEGRATED CONTROL.

IS THERE VOLTAGE GREATER THAN

12VDC BETWEEN PIN15 & PIN1?

PERFECT SPEED