43

The setting of the fan output according to the installation

should be done only through the air damper. Should you

want to adjust the setting of the combustion head, with the

burner running, turn the rod

(1)

with a 6mm wrench

(2)

as

follows:

TURN TO THE RIGHT: (SIGN + )

In order to increase the volume of air entering the

combustion chamber and thus diminishing its pressure.

There is a reduction of CO2

and the adhesion of

Figure 21

the flame to the air diffuser disc improves.

(Setting advisable for ignitions at low temperatures).

TURN TO THE LEFT: (SIGN - )

Figure 21

In order to reduce the volume of air entering the combustion chamber and thus increasing its pressure.

The CO2

improves and the adhesion of the flame to the diffuser tends to reduce. (This setting is not

advisable for ignitions at low temperatures).

In any case do not bring the combustion head setting more than one point away from that indicated in the

schedule. One set-point corresponds to 3 turns of the rod; a hole

(3)

at its end facilitates counting the

number of turns.

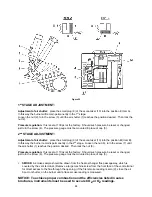

AIR DAMPER ADJUSTMENT:

The settings indicated in the schedule refer to the burner with its metal cover fitted and the combustion

chamber with “zero” depression. These regulations are purely indicative. Each installation however, has

its own unpredictable working conditions: actual nozzle output; positive or negative pressure in the

combustion-chamber, the need of excess air, etc. All these conditions may require a different air damper

setting.

It is important to take account of the fact that the air output of the fan differs according to whether

the burner has its metal cover fitted or not.

Therefore we recommended to proceed as follows:

•

adjust the air damper as indicated in the schedule (3);

•

mount the cover, simply by means of the upper screw;

•

check smoke number;

•

should it become necessary to modify the air output, remove the cover by loosening the screw,

adjust the air damper, remount the cover and finally recheck the smoke number.

The burner is provided with a hydraulic device controlled by the economizer which reduces the max.

output of oil and air by approximately 70%.

Summary of Contents for OH6FA072D48N

Page 5: ...2...

Page 33: ...30 Heating Speed Set ups 2 Stage OH6FX072DV4 Figure 18 2 ECM 2 stage blower motor speed chart...

Page 64: ...61 VIII Sequence of Operations Flow Chart...

Page 65: ...62...

Page 66: ...63 IX Trouble Shooting Flow Chart...

Page 67: ...64...

Page 68: ...65...

Page 69: ...66...

Page 70: ...67...

Page 72: ...69 Appendix A Replacement Parts Replacement Parts for OH6FA072D...

Page 73: ...70 Replacement Parts for OH8FA119D...

Page 74: ...71 Appendix B Wiring Diagrams OH6FA072D48 PSC Wiring Diagram...

Page 75: ...72 OH6FA072DV4 ECM Wiring Diagram...

Page 76: ...73 OH6FX072DV4 ECM 2 Stage Wiring Diagram...

Page 77: ...74 OH8FA1119D60 PSC Wiring Diagram...

Page 78: ...75 OH8FA1119DV5 ECM Wiring Diagram...

Page 79: ...76...