46

a. With the oil shut off, remove the 1/8 in. NPT threaded pipe plug located on the lower rear side of the oil

pump, refer to Figure 22. Attach a pressure gage, capable of measuring pressure in pounds per square

inch gage, PSIG, in this opening, on the discharge side, of the oil pump.

NOTICE: It may be necessary to remove the oil pump to attach the plumbing

required to connect a pressure gage to the pump.

b. Turn on the fuel oil and cause the appliance to activate the heating section by answering a “call for

heat”.

NOTICE: It may be necessary to bleed air from the oil line before the burner can

be fired.

c. Allow the heating section to operate for 10 to 15 minutes.

d. Note the oil pressure at the pump.

e. To adjust the pressure, use a common screwdriver to turn in the pressure adjustment screw, located

on the upper front of the oil pump body.

f. Allow the fuel flow rate to stabilize for a moment. Recheck the oil pressure.

g. If required, repeat the oil pressure adjustment again.

h. When the input rate adjustment has been completed, shut off the fuel oil to the appliance. Remove the

pressure gage. Reinstall the pipe plug using a thread compound resistant to the action of LP gases and

fuel oil.

To insure the combustion air supply is adequate, it is now necessary to repeat the steps in the previous

Initial Burner Adjustment

section of this manual.

4. Setting Supply Air Temperature Rise:

: To avoid injury from moving parts or electrical shock, shut off the

power to the appliance before removing supply air blower compartment door and

servicing this appliance.

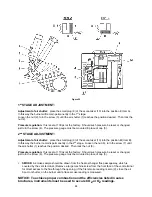

All OH6 & OH8 models are designed and wired at the factory for a blower speed during heating that

should result in an approximate temperature rise of 65°F. The temperature rise through the heating

section, for any given blower speed, may vary depending on a number of factors. A few of these factors

are variations in, the actual resistance of the duct system to airflow at any time, the return air

temperatures, and the fuel oil heating value.

Also, fouling of the heat exchanger surfaces will reduce temperature rise. In general, a lower temperature

rise through the heating section will result in higher heating efficiency.

Temperature rise = supply air temperature - return air temperature.

After 15 to 20 minutes of continuous operation, the temperature rise through the furnace must fall within a

range of 50° to 80° F. If the outlet or supply duct temperature is too high, check to make sure the return

air filter is clean, the return air registers are free from obstruction, the outlet registers are properly

adjusted and clear, and the supply and return air ducts are open. The circulating air blower is not moving

enough air if the supply air temperature is still too high. Before proceeding further, turn off the power

supply to the appliance and remove the vestibule cover. The speed of the blower must be increased by

changing the switch setting on the control board, please refer to Figure 18.

Summary of Contents for OH6FA072D48N

Page 5: ...2...

Page 33: ...30 Heating Speed Set ups 2 Stage OH6FX072DV4 Figure 18 2 ECM 2 stage blower motor speed chart...

Page 64: ...61 VIII Sequence of Operations Flow Chart...

Page 65: ...62...

Page 66: ...63 IX Trouble Shooting Flow Chart...

Page 67: ...64...

Page 68: ...65...

Page 69: ...66...

Page 70: ...67...

Page 72: ...69 Appendix A Replacement Parts Replacement Parts for OH6FA072D...

Page 73: ...70 Replacement Parts for OH8FA119D...

Page 74: ...71 Appendix B Wiring Diagrams OH6FA072D48 PSC Wiring Diagram...

Page 75: ...72 OH6FA072DV4 ECM Wiring Diagram...

Page 76: ...73 OH6FX072DV4 ECM 2 Stage Wiring Diagram...

Page 77: ...74 OH8FA1119D60 PSC Wiring Diagram...

Page 78: ...75 OH8FA1119DV5 ECM Wiring Diagram...

Page 79: ...76...