All installations and services must be performed by qualified service personnel.

7

H. HEAT EXCHANGER CLEANING INSTRUCTIONS:

c

WARNING: THE HEAT EXCHANGER MUST BE CLEANED BY A QUALIFIED

SERVICE PERSON.

It is important to inspect and clean the heat exchanger once a year, or as necessary, to remove any build-up of soot.

A layer of soot on the inside of the heat exchanger will act as an insulator and reduce heat transfer, resulting in less

efficiency.

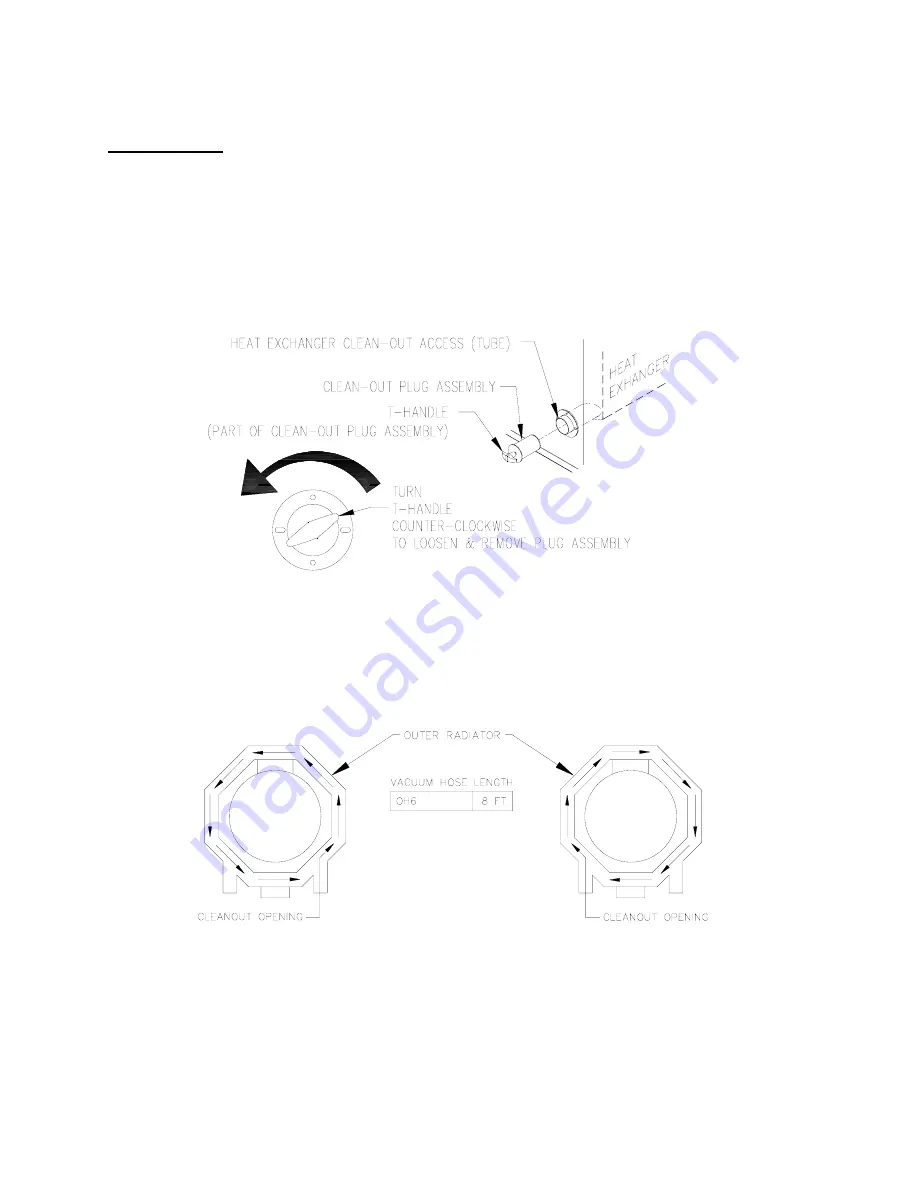

To clean the heat exchanger, first turn off all power to the unit. Remove clean-out plugs, the vent connector pipe to

the chimney, the burner, and the burner mounting plates. When removing the clean-out plugs, turn T-handle

counterclockwise approximately two (2) full turns or just until the plug is able to be pulled from tube. Take care not

to remove T-handle from assembly.

Fig. 15: Clean-out plug removal

With access to the inside of the heat exchanger through the burner area, clean-out openings, and vent pipe

connection, it is possible to use a long, flexible wire brush and an industrial type vacuum cleaner to remove any soot

build-up.

NOTE:

A one inch (outside diameter) vacuum cleaner hose will fit into the radiator.

To vacuum and brush the outer radiator of the heat exchanger, go through the clean-out openings in both directions,

as shown in figure 16, below.

Fig. 16: Recommended method and device for cleaning inside of heat exchanger.

Reassemble the furnace to its original construction*. Remount the burner being certain that the air tube is properly

inserted into the chamber opening (see section F). If heavy soot deposits were found in the heat exchanger, this may

indicate the burner is out of adjustment.

*When returning clean-out plugs to their original position, insert plug and turn T-handle clockwise 2-3 turns or until

plug cannot be pulled from the clean-out access tube. This is sufficient for sealing the access tube.