All installations and services must be performed by qualified service personnel.

10

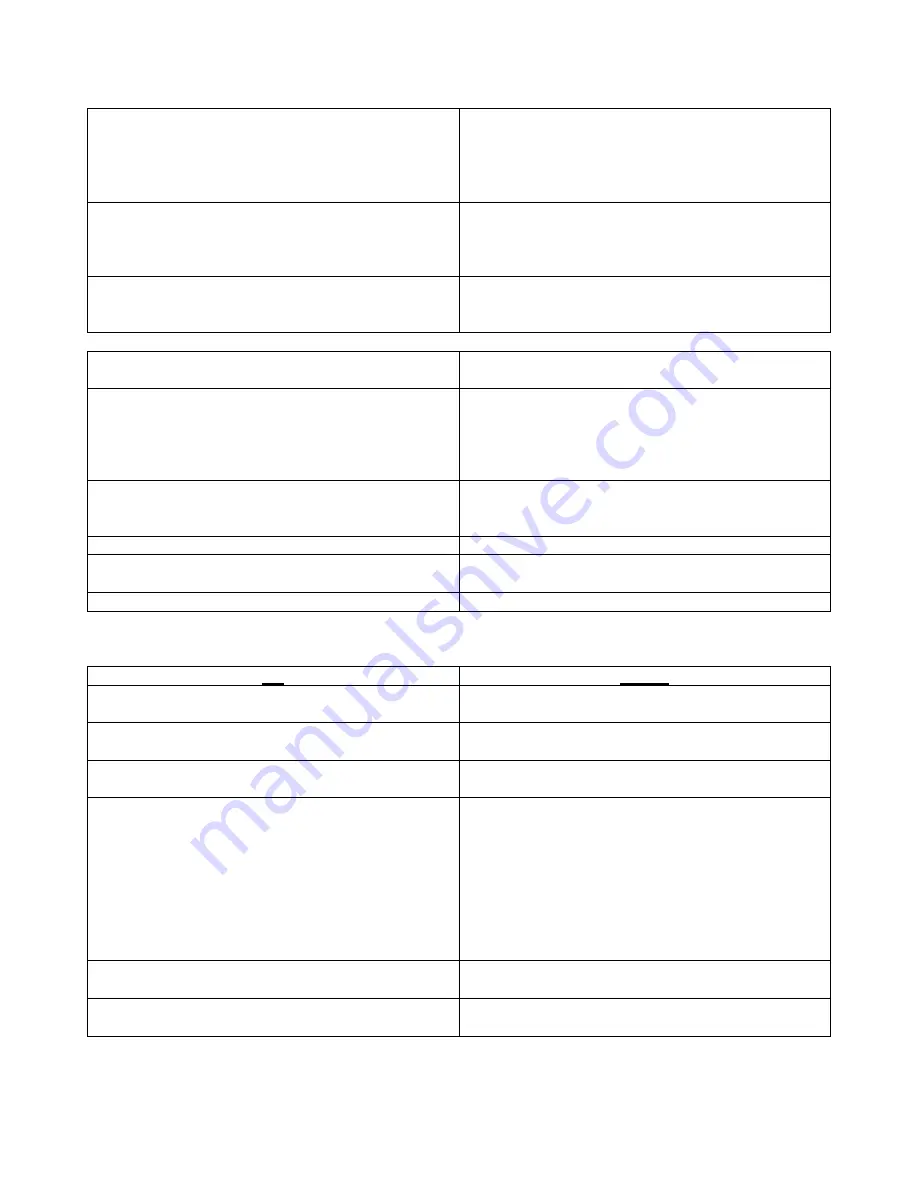

Stays at low CFM despite system call for cool or

heat CFM

Check low voltage (T’stat) wires and connections

Verify fan is not in delay mode – wait until delay

complete

“R” missing/not connected at motor

Perform motor/control replacement check

Stays at high CFM

“R” missing/not connected at motor

Is fan in delay mode? – wait until delay time

complete

Perform motor/control replacement check

Blower won’t shut off

Current leakage from controls into G,Y or W?

Check for Triac switched t’stat or solid state

relay

Excessive noise

Determine if it’s air noise, cabinet, duct or motor

noise – interview customer, if necessary

Noisy blower or cabinet

Check for loose blower housing, panels, etc.

High static creating high blower speed?

Check for air whistling thru seams in ducts,

cabinets or panels

Check for cabinet/duct deformation

“Hunts” or “puffs” at high CFM (speed)

Does removing panel or filter reduce “puffing”?

Reduce restriction

Reduce max airflow

Evidence of Moisture

Motor failure or malfunction has occurred and

moisture is present

Replace motor and perform

Moisture Check

Evidence of moisture present inside air mover

Perform

Moisture Check

DO

DON’T

Check-out motor, controls, wiring and

connections thoroughly before replacing motor

Automatically assume the motor is bad.

Orient connectors down so water can’t get in

Install “drip loops”

Locate connectors above 7 and 4 o’clock

positions

Use authorized motor and control model #’s for

replacement

Replace one motor or control model # with

another (unless an authorized replacement)

Keep static pressure to a minimum:

Recommend high efficiency, low static

filters

Recommend keeping filters clean

Design ductwork for min static, max

comfort

Look for and recommend ductwork

improvement, where necessary, in

replacement

Use high pressure drop filters – some have ½”

H

2

O drop!

Use restricted returns

Size the equipment wisely

Oversize system then compensate with low

airflow

Check orientation before inserting motor

connectors

Plug in power connector backwards

Force plugs

Summary of Contents for OL11-105FDBE

Page 2: ......