All installations and services must be performed by qualified service personnel.

6

When the call for cool is satisfied, the “CC” terminal is de-energized and the cooling off delay of 45 seconds is

started. Forty-five seconds later the blower speed ramps toward zero and the control reverts to Standby Mode.

Dehumidification Operation

If a call for dehumidification is received while the Cool Mode is active, blower speeds will be reduced.

The speed value will be selected from the DEHUM column of the CFM Tables. This input may only be

used on systems using a thermostatic expansion valve (TXV) on the evaporator.

Anti-Short Cycle Operation

To prevent compressor short cycling, a call for cooling will be ignored for four minutes after the

termination of any cooling call. The anti-short cycle delay is also in effect at power-up.

Heat Mode

When a call for heat ("W") is received from the thermostat, if the “Cool” mode is not already active, the “T-T”

terminal is energized and the blower on delay is started. The on-off pattern of DIP switch SW2 (positions 1

and 2) select one of four blowers on delay values (see Table 1). When the delay time has elapsed, a speed

value is read from DIP switch SW1 positions 1 through 3 (see the CFM Tables) and the blower is ramped up

to that speed. The 2-Stage control will be operated by t-stat through W1 and W2. For 2-stage control with a

single stage t-stat, call for heat will go through W2. When W2 is energized, low fire is activated for 15

minutes. If a call for heat still exists, high fire will be activated and will continue until the demand for heat

has been satisfied.

Counterflow units, in addition, will run at a low blower speed shortly after the burner is brought on. They will

continue at that speed until the delay time has elapsed.

The control remains in steady heat mode until the thermostat is satisfied. When the call for heat signal is

removed, the “T-T” terminal is de-energized and the blower off delay is started. The on-off pattern of DIP

switch SW2 (positions 3 and 4) select one of four blower off delay values (see Table 1). When the delay time

has elapsed, the blower is ramped toward zero.

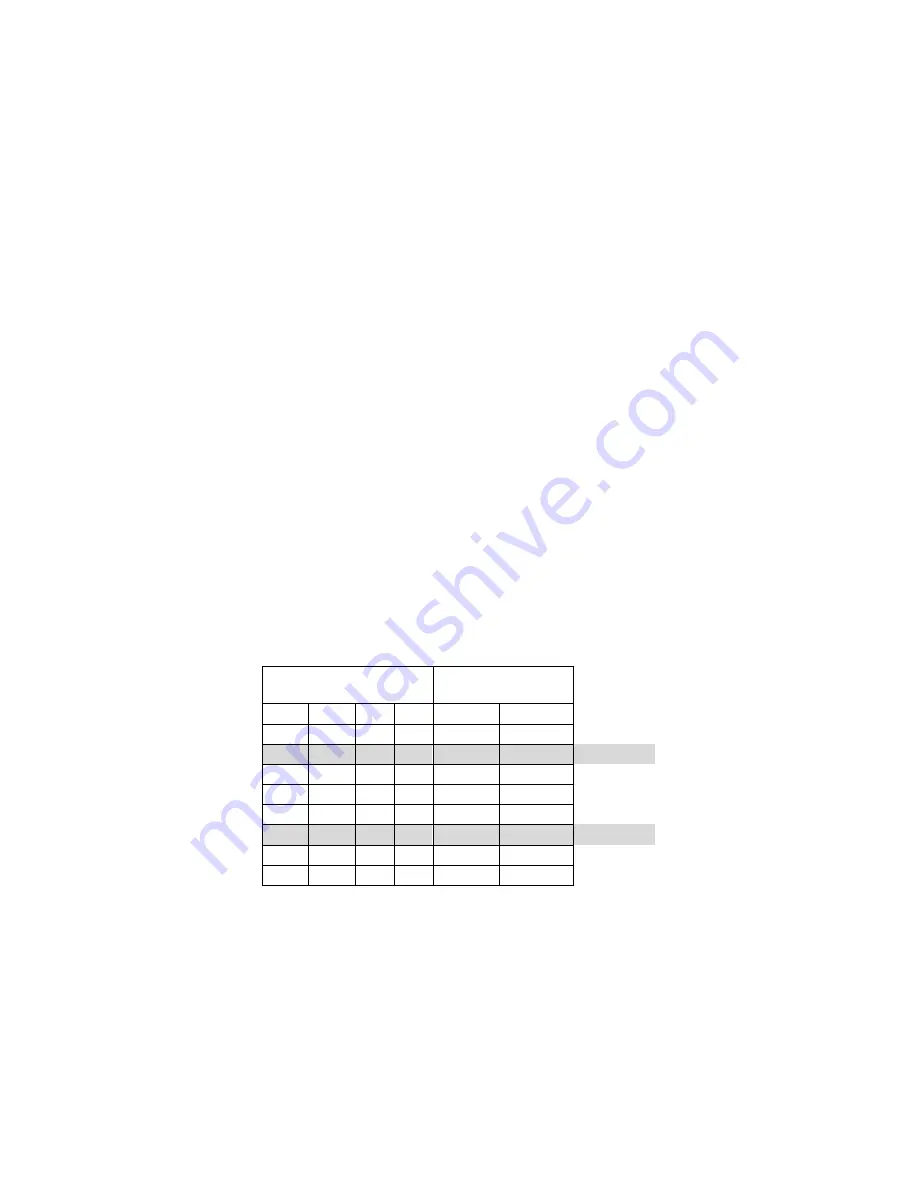

Table 1:

ON and OFF Blower Delay Time Switch Settings

DIP SWITCH 2 SECTION

STATE

BLOWER DELAY

TIMES

2

1

4

3

ON - SEC

OFF - MIN

OFF

OFF

30

OFF

ON

60

Factory Set

ON

OFF

120

ON

ON

240

OFF

OFF

2

OFF

ON

4

Factory Set

ON

OFF

6

ON

ON

8

Motor Blower Speed

Three blower speed outputs are provided. A “G” call for fan will provide the Low speed only. A “W”

heat call will provide the Heat speed only. A “Y” cooling call will provide the Cool speed only.

In the case of thermostat calls for “Y” and “W” together, blower speed selection will be determined by the

input that was first initiated. In the case where the control is in a cooling mode with both “Y” and “W”

inputs energized and then the “Y” input is removed, the cooling blower off time will be executed prior to

the control switching into a heating mode. In the case where the control is in a heating mode with both

“Y” and “W” inputs energized and then the “W” input is removed, the heating blower off time will be

Summary of Contents for OL11-105FDBE

Page 2: ......