All installations and services must be performed by qualified service personnel.

7

III. STARTING THE UNIT

A. INITIAL OPERATION OF THE FURNACE

WARNING:

To avoid possible explosion, DO NOT attempt to light the burner if:

1.

Oil has accumulated in the base of the combustion chamber.

2.

The furnace is full of fuel vapors.

3.

The combustion chamber is very hot.

CAUTION:

The oil burner must be installed and adjusted using recently (within the last year)

calibrated combustion instruments by a qualified heating contractor prior to placing the furnace in

operation. Refer to this manual and the oil burner instruction manual for details.

To minimize initial fuel oil and combustion odors, ventilate the building well while operating the

furnace for the first time.

Do not run the oil pump dry (without oil) for more than two (2) minutes. Damage to the oil pump

may result.

1)

Turn the electrical disconnecting switch to the “OFF” position.

2)

Set the room thermostat above room temperature.

3)

Be sure the oil tank is full of clean # 2 fuel oil.

4)

Open all shutoff valves in the oil line.

5)

Turn on the electrical disconnecting switch and prime the burner oil pump according to

the pump manufacturer’s instructions.

6)

When ignition is established, make a temporary air adjustment for a clean, smoke-free

flame. At this point, the final burner adjustment should be made using test

instruments to

measure oil pump pressure, smoke number, carbon dioxide (CO2), carbon monoxide (CO),

draft, and flue gas temperature.

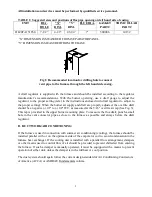

B. BURNER ADJUSTMENT

In order to achieve the best combustion efficiency, the following procedure is recommended.

Measure the oil pump pressure. If required, adjust it to deliver the appropriate pressure for the

burner. See Table 2 for correct pump pressures.

Carbon Dioxide (CO2) and Carbon Monoxide (CO) – In order to assure that proper and safe

combustion are taking place, carbon dioxide and carbon monoxide measurements must be taken.

A CO2 reading within the limits of Table 2 with no measurable CO is desirable. The maximum

acceptable CO reading is less than 50 PPM. If the CO reading is too high, open the burner air

shutter, or air band, slightly to permit more combustion air to the flame. Recheck the CO level

and adjust as required.

Draft – Draft measurements should be taken through the overfire port and in the vent connector,

not more than 12 inches away from the furnace outlet. A 5/16 in. hex washer head bolt plugs the

overfire port in the burner mounting plate. Remove the bolt and insert a suitable draft

measurement gage. After the chimney (or stack gas passageway) has warmed up to operating

temperature, approximately 15 to 20 minutes of burner operation, adjust the barometric damper

Summary of Contents for OL20FA151T60 Series

Page 2: ......

Page 5: ...All installations and services must be performed by qualified service personnel iii...

Page 19: ...All installations and services must be performed by qualified service personnel 13...

Page 21: ...All installations and services must be performed by qualified service personnel 15...

Page 23: ...All installations and services must be performed by qualified service personnel 17...