All installations and services must be performed by qualified service personnel.

3

The Field vent kit is set up with 4 inch diameter vent pipe with concentric through-the-wall vent termination/inlet air

vent hood. The combustion air inlet pipe diameter is also 4 inch diameter. For Beckett, the combustion air inlet pipe

will be reduced to 3” diameter with the Beckett side wall vent kit.

The side wall vent may be installed either through the upper knock-out on the left side casing of the unit or vertically

out the top opening of the vestibule. The 4” flexible vent pipe included w/ Field vent kit is able to be installed at 2”

clearance to combustibles.

The combustion air inlet can be installed through the either the lower left side casing knock-out or the lower right

side casing knock-out.

B. DRAFT REGULATORS:

A draft regulator is supplied with the furnace and should be installed according to the regulator manufacturers

recommendations. With the burner operating, use a draft gauge to adjust the regulator to the proper setting. (refer to

the instructions enclosed with draft regulator to adjust to the proper setting). When the burner air supply and draft are

properly adjusted, the overfire draft should be a negative (-).01" to (-).02" WC

1

, as measured at the 5/16" overfire

air tap (See Fig. 4). This tap is provided in the upper burner mounting plate. To measure the flue draft, punch a small

hole in the vent connector pipe as close to the furnace as possible and always before the draft regulator.

Note:

1. Draft overfire may be positive for high fire applications but not to exceed (+).02" WC.

C. DUCT WORK/AIR CONDITIONING/SUPPLY/RETURN AIRFLOW AND AIR TEMPERATURE:

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed parallel

with or on the upstream side of the evaporator coil to avoid condensation in the furnace heat exchanger. If the

cooling unit is installed with a parallel flow arrangement, dampers or other means used to control flow of air should

be provided to prevent chilled air from entering the furnace. If such a damper is manually operated, it must be

equipped with a means to prevent operation of either unit, unless the damper is in the full heat or cool position.

The supply/return airflow shall be set to obtain an air temperature rise, across the furnace, in the range of 55º to

85ºF. Since the flow resistance of each duct system is slightly different, the airflow (fan speed) may have to be

changed in the field to achieve a satisfactory temperature rise.

One way to measure the temperature rise across the furnace is to insert temperature measuring devices (e.g.

thermometers) into the return air duct and into the supply air duct about 12 inches from the furnace. After the furnace

has been firing continually for over 20 minutes, read the temperature difference between the two (2) thermometers.

The temperature difference should not exceed 85ºF, nor be less than 55ºF. A temperature rise of 70ºF is considered

to be optimum for comfort.

The blower (fan) speed fan is adjusted by changing the fan motor winding energized by the control system. The

furnace is set on fan speed, “ML”, at the factory, refer to page 13 of this manual. To adjust the fan speed, change

corresponding wire from the appropriate fan speed to the “HEAT” tap on the control.

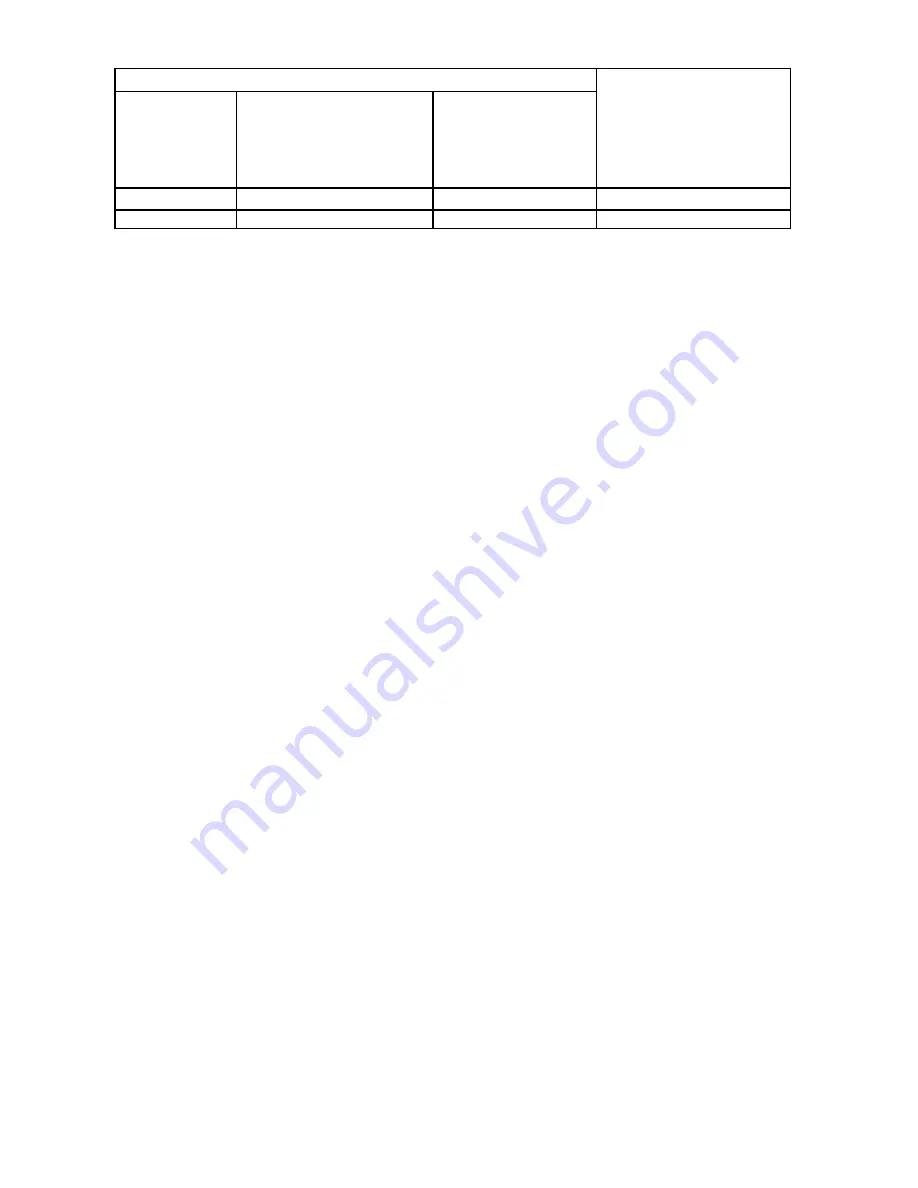

FIELD VENT TERMINATION

KIT

SIDE WALL VENT

ACCESSORIES KIT

COMBUSTION AIR INTAKE

HOOD KIT

(15’ application MAX)

(BURNER SPECIFIC)

(FOR COMBUSTION AIR

APPLICATIONS ONLY)

PART NUMBER

PART NUMBER

PART NUMBER

Beckett AFG

AOPS8393

AOPS8394

AOPS8397

Beckett NX

AOPS8393

AOPS8412

AOPS8413

BURNER

SIDE WALL VENTING APPLICATION ORDER INFORMATION

Summary of Contents for Spirit VHF-ABE

Page 16: ...All installations and services must be performed by qualified service personnel 13...

Page 17: ...All installations and services must be performed by qualified service personnel 14...

Page 18: ...All installations and services must be performed by qualified service personnel 15...

Page 20: ...All installations and services must be performed by qualified service personnel 17...