6

A. CHIMNEY

:

The furnace must be connected to an adequate chimney or an approved vent in accordance with these

instructions. An adequate chimney is one that is sealed and lined with the capability of producing a (-).04"

WC flue draft and having the capacity to handle the amount of stack gases that are introduced into it. A

chimney with an internal construction of corrosion resistant tile, stainless steel, or some other material

that will withstand flue gas temperatures up to 900°F is required.

Qualified service personnel must perform all installations and services.

The following are common chimney requirements necessary for the furnace to operate correctly:

A masonry chimney serving an THV1M119A* oil fired furnace must comply with local codes and NFPA

Standard for Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances (NFPA211-1996 or latest

edition).

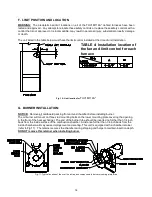

1. PREVENTION OF CHIMNEY CONDENSING:

Stack gas may do one of two things as it escapes up the chimney:

A. Remain entirely in a gaseous state if the internal chimney wall temperature is above the dew

point

B.

Condense water vapor on the chimney walls if they are chilled below the dew point.

Condensing will always occur on chimney walls whose temperatures are below the dew point, but the

condensate may evaporate when the walls warm above the dew point. If the chimney wall temperature

does not exceed the dew point during the heating cycle of the furnace, the moisture may accumulate in

large enough quantities to cause problems such as corrosion of a metal chimney (especially plain steel or

galvanized steel), erosion and break up of a tile liner in a masonry chimney and, in severe cases,

corrosion of the heat exchanger. Condensate also could enter the home through cracks or joints in the

chimney in a worse case situation.

Condensation most likely will not occur at the bottom of the chimney because the stack gas heats the

chimney walls as it rises and the bottom will be heated first. This heating of the walls will cause the stack

gas temperature to drop, which in turn may reduce the stack gas temperature below dew point, causing

condensation to appear on the upper part of the chimney first. This condensation may then run down

inside the chimney and drip back as far as the flue pipe and heat exchanger, where corrosion may occur,

if not treated.

To prevent condensation, it is necessary that the internal chimney wall temperature always be kept above

the dew point. If the chimney is a masonry type, it may have to be fitted with a flue liner, when the

temperature loss is too great for the furnace. If the chimney is a metal type, then an "all fuel" chimney

must be used, such as a Class "A" triple wall or insulated metal chimney. A liner will act as an insulator

and reduce the stack gas temperature loss. Insulation may be added around the liner for further

temperature stability. If the chimney is on the home's exterior or passes through a sizable, unheated area

of the building, such as a porch, high ceiling attic, etc., and condensing occurs, the chimney must be

insulated around its exterior to help the flue hold its temperature. Also, check to see if the chimney is too

large for the furnace and other appliances connected to it. If so, reduce to proper size (see Appendix E of

NFPA31) by lining. Be sure to use stainless steel liners, such as stainless types 430, 304, or for the

toughest corrosion problems, type 316. If the chimney is the correct size for the unit and condensing still

occurs, then insulating the vent connector and/or reducing the efficiency of the furnace may have to be

done to raise the chimney temperature.

More detailed information may be obtained from the latest edition of the ASHRAE HVAC Systems and

Equipment Handbook.

Summary of Contents for THV1M119A960SA

Page 2: ......

Page 4: ......

Page 6: ...2...

Page 36: ...32 V Sequence of Operations Flow Chart...

Page 37: ...33...

Page 38: ...34 VI Trouble Shooting Flow Chart...

Page 39: ...35...

Page 40: ...36...

Page 41: ...37...

Page 42: ...38...

Page 44: ...40 Appendix A Replacement Parts for THV1M119A...

Page 45: ...41...

Page 46: ...42 Appendix B THV1M119A960SA PSC Wiring Diagram...