1-4

8600 Series

Thermo Scientific

Section 1

Installation and Start-up

micro

board

battery

bracket

battery

switch

probe

access

port

Figure 1-7.

Freezer Left Side - Sidecar panel removed

O

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

aaaaaaaa

O

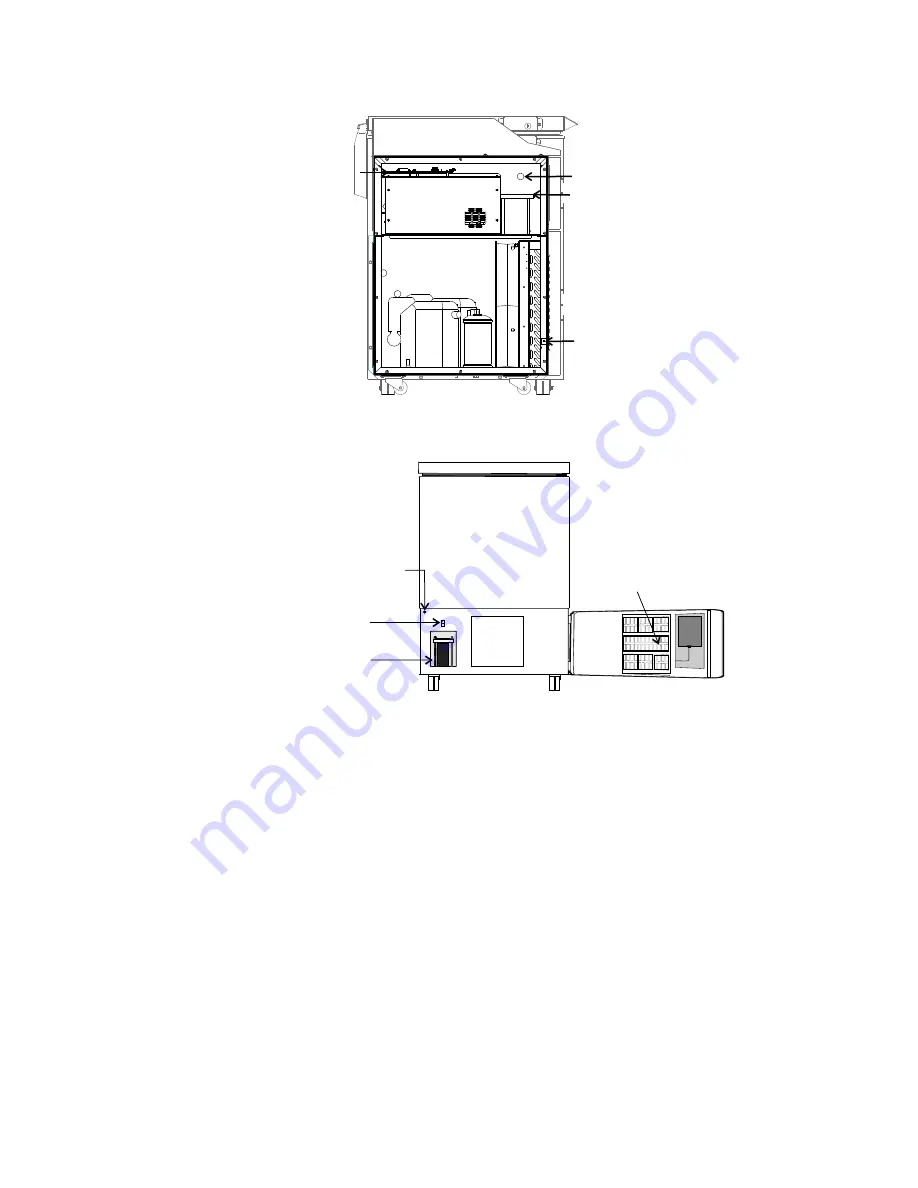

System

battery

Battery

switch

Thermocouple

interconnect jack

To

remove filter

Figure 1-8.

3 cu ft Models

Summary of Contents for Forma 8600 Series

Page 55: ...8600 Series 8 1 Thermo Scientific Section 8 Spare Parts...

Page 75: ...8600 Series 9 1 Thermo Scientific Section 9 Refrigeration Schematics...

Page 76: ...9 2 8600 Series Thermo Scientific Section 9 Refrigeration Schematics...

Page 77: ...8600 Series 9 3 Thermo Scientific Section 9 Refrigeration Schematics...

Page 78: ...9 4 8600 Series Thermo Scientific Section 9 Refrigeration Schematics...

Page 79: ...8600 Series 9 5 Thermo Scientific Section 9 Refrigeration Schematics...

Page 80: ...9 6 8600 Series Thermo Scientific Section 9 Refrigeration Schematics...

Page 81: ...8600 Series 10 1 Thermo Scientific Section 10 Electrical Schematics...

Page 82: ...10 2 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 83: ...8600 Series 10 3 Thermo Scientific Section 10 Electrical Schematics...

Page 84: ...10 4 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 85: ...8600 Series 10 5 Thermo Scientific Section 10 Electrical Schematics...

Page 86: ...10 6 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 87: ...8600 Series 10 7 Thermo Scientific Section 10 Electrical Schematics...

Page 88: ...10 8 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 89: ...8600 Series 10 9 Thermo Scientific Section 10 Electrical Schematics...

Page 90: ...10 10 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 91: ...8600 Series 10 11 Thermo Scientific Section 10 Electrical Schematics...

Page 92: ...10 12 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 93: ...8600 Series 10 13 Thermo Scientific Section 10 Electrical Schematics...

Page 94: ...10 14 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 95: ...8600 Series 10 15 Thermo Scientific Section 10 Electrical Schematics...

Page 96: ...10 16 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 97: ...8600 Series 10 17 Thermo Scientific Section 10 Electrical Schematics...

Page 98: ...10 18 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 99: ...8600 Series 10 19 Thermo Scientific Section 10 Electrical Schematics...

Page 100: ...10 20 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 101: ...8600 Series 10 21 Thermo Scientific Section 10 Electrical Schematics...

Page 102: ...10 22 8600 Series Thermo Scientific Section 10 Electrical Schematics...

Page 103: ...8600 Series 10 23 Thermo Scientific Section 10 Electrical Schematics...

Page 104: ...10 24 8600 Series Thermo Scientific Section 10 Electrical Schematics...