8

所有的指示,并按照铭牌上注明的设计范围进行操作。

4.1 Location

安装位置

Install the unit in a level area free from vibration with a minimum of 10cm of space on the sides and top and

15cm at the back of the unit. See the install space dimensions below in section 4.2.

将设备安装在一块平整的无

振动场地,设备两侧及顶端应最少保留

10

厘米的空间,背面最少保留

15

厘米的空间。

见下文第

4.2

条:安装

空间尺寸。

Do not position the equipment in direct sunlight or near heating diffusers, radiators, or other sources of heat.

The ambient temperature range must be between 15°C and 32°C.

设备不要放置在阳光直射或靠近加热扩散器、

散热器或其他热源的地方。

环境温度范围必须在

15°C-32°C

。

4.2 Install Space Dimensions

安装空间尺寸

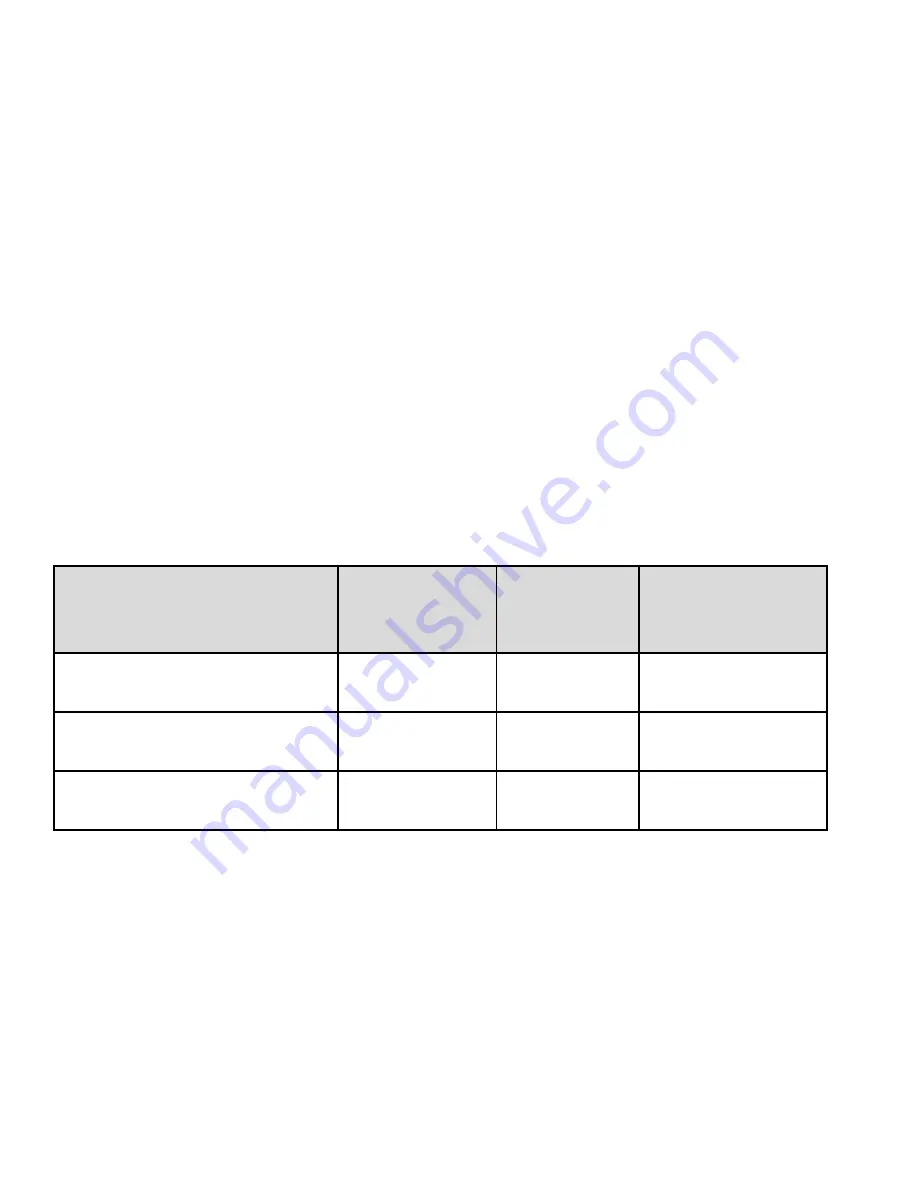

Allow adequate space around the unit after installation to provide for airflow. Be certain to allow for door

swing, and doors with handles must be capable of opening at least 85 degrees from the closed position without

touching an adjacent wall. The table below shows the required clearance dimensions.

设备安装后周围须留有足

够的空间允许气流通过。务必留出门的摆动空间,带把手的门须至少能够从关闭位置打开到

85

度且不会碰到相

邻的墙面。下表显示了必需的间隙尺寸。

Minimum Clearance Areas

最小间隙区域

Model PLR 221

and PLR 1006

型号

PLR221

和

PLR 1006

Model PLR 386

型号

PLR 386

Model PLF 276

型号

PLF 276

Minimum Clearance – Top

顶部最小

间隙

10 cm (min)

(最小

尺寸)

10 cm (min)

(最

小尺寸)

10 cm (min)

(最小尺寸

)

Minimum Clearance – Side,

两侧最

小间隙

10 cm (min)

(最小

尺寸)

10 cm (min)

(最

小尺寸)

10 cm (min)

(最小尺寸

)

Minimum Clearance – Back, Free

Standing,

自由站立时背面最小间隙

15 cm (min)

(最小

尺寸)

15 cm (min)

(最

小尺寸)

15 cm (min)

(最小尺寸

)

Table 3 Clearance Dimensions

表

3

间隙尺寸

4.3 Operational/Field Environment

操作

/

现场环境

The table below displays the Operational/Field Environment

下表显示了显示操作

/

现场环境