Thermo Scientific Revco Cryogenic Storage Freezers

Installation and Operation

7

7 Maintenance and Troubleshooting

WARNING!

Unauthorized repair of your freezer will

invalidate your warranty. Contact Technical Service at

1-800-438-4851 for additional information.

CAUTION!

Maintenance should only be performed

by trained personnel.

7.1

Condenser Maintenance

7.1.1 Cleaning the Condenser

Clean the condenser at least every six months; more often if the

laboratory area is extremely dust prone.

To clean the condenser, complete the following steps:

1. Pull the grill open.

2. Remove the filter. Check the fans. If a fan is not operating,

contact an Authorized Service Company immediately.

3. Vacuum the condenser.

4. Replace the filter and close the grill.

7.1.2 Cleaning the Condenser Filter

Clean the condenser filter every two or three months.

1. Pull the grill open.

2. Remove the filter.

3. Shake the filter to remove loose dust, rinse the filter in clean

water, shake the excess water from the filter, and replace the

filter.

4. Close the grill.

7.2

Gasket Maintenance

Periodically check the gaskets around the door or lid for

punctures or tears. Leaks are indicated by a streak of frost which

forms at the point of gasket failure. Make sure that the cabinet is

level (refer to Section 5.3 on page 2 for leveling information).

Keep the lid gasket clean and frost free by wiping gently with a

soft cloth.

7.3

Defrosting the Freezer

Defrost the freezer once or year or whenever the ice buildup

exceeds 3/8”.

To defrost, complete the following steps:

1. Remove all products and place in another cabinet.

2. Turn off the freezer.

3. Open the outer door and all inner doors.

4. Let the freezer stand with the door open for at least 24 hours.

This allows both the interior and foamed refrigerant system

to warm to room temperature.

5. Dispose of the ice and wipe out any water standing in the

bottom of the cabinet.

6. If there is freezer odor, wash the interior with a solution of

baking soda and warm water. Clean the exterior with any

common household cleaning wax.

7. Close the doors, restart the freezer and reload, following the

instructions in Section 3.1 on page 1.

7.4

Alarm Battery Maintenance

Have a technician check the condition of the alarm battery at

least once a year.

To replace the alarm battery, complete the following steps:

1. Remove the front grill. The alarm battery is located directly

behind the grill. The terminals are the “push on” type.

2. Grasp the terminal with pliers and work it gently back and

forth while pulling it off. The fittings are tight.

3. Remove the battery and put the new battery in place.

Note:

You may have to cut a strip of silicone rubber in order to

remove the battery.

4. Connect the battery terminals and replace the front grill.

7.5

Frame Heater Switch

Cryogenic chest freezers (-140º and -150º C) have a frame heater

switch which can be used to prevent or remove condensation

near the freezer compartment lid. The switch is located in back of

the unit near the top center, to the right of the junction box.

Turning the switch to the up position heats up the frame around

the lid.

Heating the frame has no effect on interior cabinet temperature.

You can turn on the switch whenever there is condensation near

the lid.

7.6

Troubleshooting Procedures

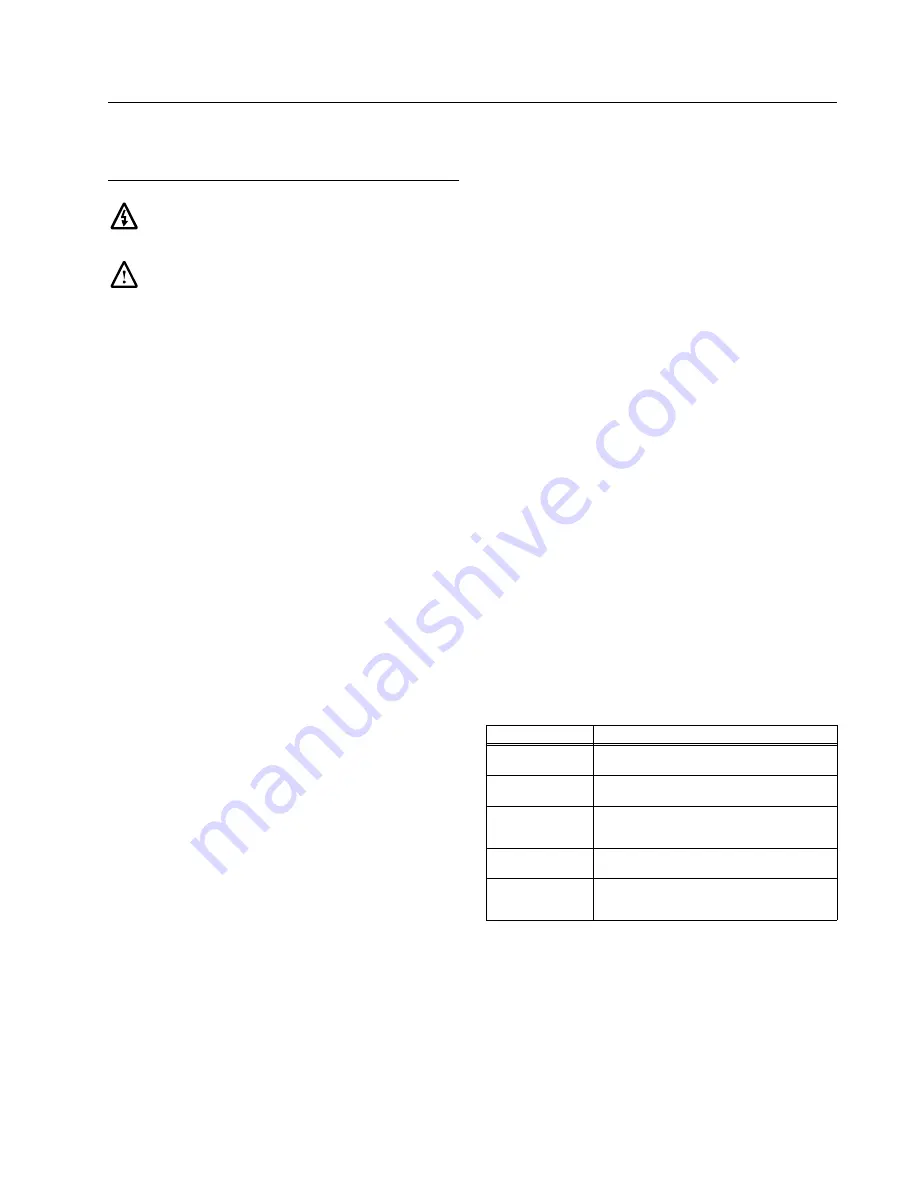

Table 2.

Troubleshooting Procedures

Problem

Solution

Check Fuse

indicator is on.

Surge protector is blown. Call an Electronics

Technician to check the equipment.

Clean Filter

indicator is on.

Condenser filter is dirty. Refer to Section 7.1.2.

Alarm Battery Low

indicator is on.

Alarm battery is low on charge. Have a

technician check the alarm battery. Refer to

Section 7.4.

Voltage Boost

indicator is on.

Low incoming line voltage to the freezer. Call an

electronics technician to check the power supply.

No display, no fans

running.

No power to the unit. Call a qualified electrical

service technician to check the service breaker

to the outlet.