Site Selection

Install hot plate on a sturdy surface and allow space for

ventilation.

The electrical specifications are listed on the specification

plate on the side of the hot plate. Consult customer serv-

ice if your electrical service is different than those listed

on the specification plate. Prior to connecting your Type

2200 hot plate to your electrical supply, be sure the dial

switch is in the OFF position.

7

Installation

Warning

Use a properly grounded electrical

outlet of correct voltage and current

handling capacity.

Do not use in the presence of flamma-

ble or combustible materials; fire or

explosion may result. This device con-

tains components which may ignite

such materials.

Caution

Space unit 6 inches from combustible

materials. This permits the heat to

escape so as not to create a possible

fire hazard.

Caution

Do not place metal containers, metal

foil, or any insulating materials on

heating surface. This action may per-

manently damage the aluminum heat-

ing surface.

Caution

Gross weight of items placed on top of

hot plate should not exceed 40 lbs.

(18.1 kg).

Summary of Contents for HPA2230M

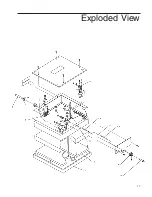

Page 17: ...17 Exploded View ...

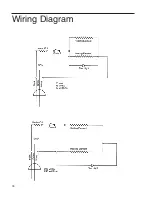

Page 18: ...18 Wiring Diagram ...