MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 12 di 31

5

INSTALLATION

5.1

CHOISES OF THE PLACEMENT

Before the installation decide with the client the exact position where to place

the unit, paying attention to the following points:

The base must be designed to bear the unit weight;

Respect the servicing spaces between the units and other machines

or structures in order to permit the free air circulation going in and

out from the ventilators.

Verify the servicing spaces, the condensation/evaporation battery

need minimum space for a correct suction.

5.2

Positoning

Before handling the unit, verify the lifting capacity of the means respecting the

information on the packaging.

For handling the unit on orizontal base use forklift or other means in an

adeguate way paying attention on the unit weight. In case of lifting, insert bars

in the proper holes of the unit base in order to permit the positioning of the

lifting ropes and of the safety cotter pin.

In order not to damage the unit structure by the belts, use proper protections

to be put between the belts and the unit. Position the unit in the place

indicated by the client by interposing between the base and the support, a gum

mattress (thickness min. 10 mm.) or antivibration feet (optional). Fix the unit

verifying that the base is plan and without inclinations.

Verify the easy access to the idraulic and electric part. In case of installation in

places where there could be gust, fixing the unit to the support properly using

guy rope if needed.

5.3

Handling and positioning

The units have been designed to be lifted from above by means of eyebolts

and holes in the base members.

Use retractor bars to keep the lifting wires or chains away from the unit.

Lifting procedures provided with the unit have to be respected.

5.4

Precautions for dominant winds

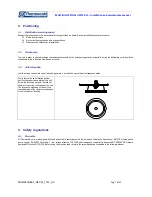

Avoid obstacles on suction and discharge sides of the units. Respect the servicing spaces as shown on the units dimensional drawings.

In case of presence of dominant winds in the installation area it is strictly necessary to avoid (for units with horizontal flow fans) that such

winds blow in front of the unit (fans discharge side). In case of unit with vertical flow fans it is strictly necessary to avoid installations

where the dominant winds could cause rejected hot air to come back to the condensing coils.

If needed, install winbreak barriers (in this case contact our offices).

5.5

Precautions against direct sunshine

The direct sunshine can raise the condensation temperature and it causes the unit stopping or the missing set-up because of the high-

pressure switch intervention.

5.6

Precautions against chimney and hot air discharge

Avoid the unit installation lee side near chimney and liquid and gas discharge.

5.7

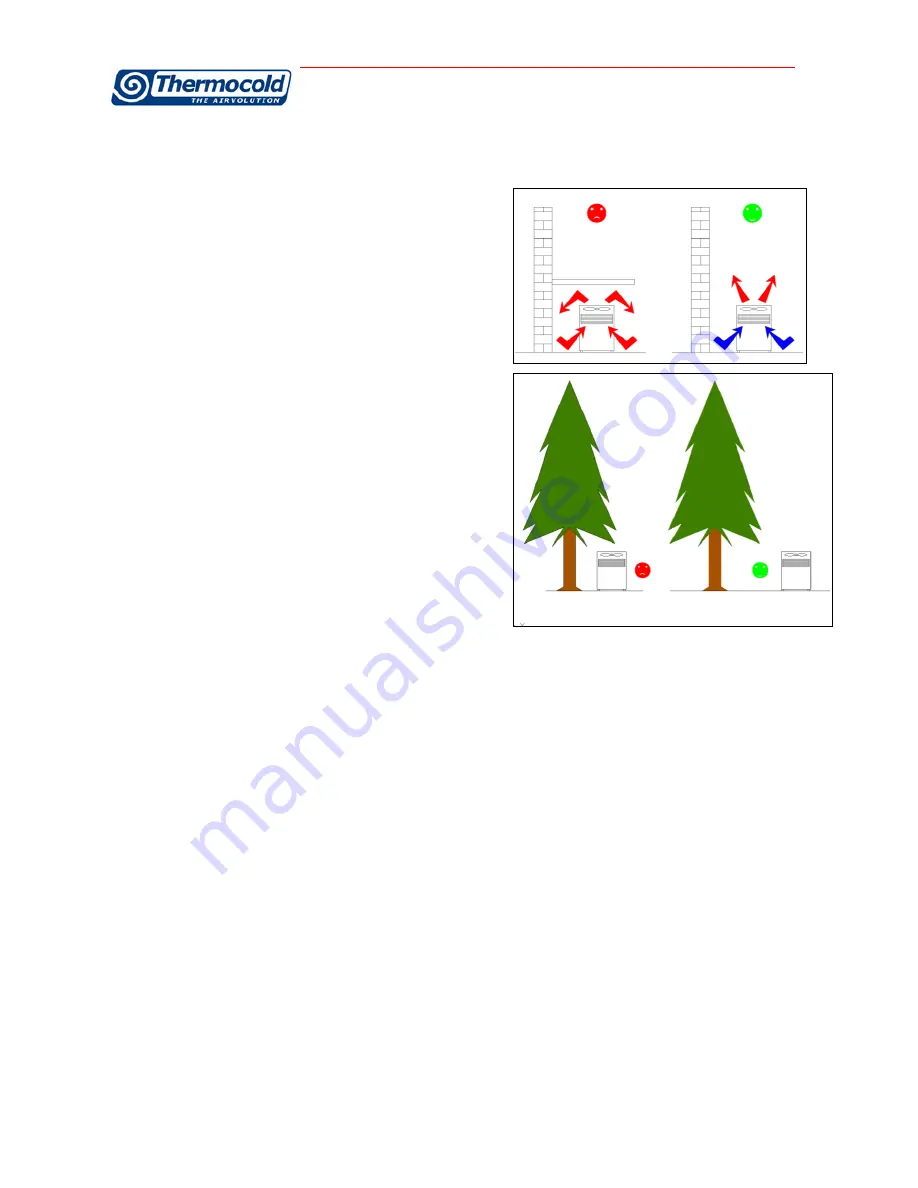

Precautions against foliage and external body

Avoid the unit installation nearby plants which could obstacle the correct air charge and discharge.

Attention

Do not use forklift trucks to lift the unit from below.

If equipment for lifting from above is not available, using rollers may move the unit.

The surface on which the unit is placed must be flat and strong enough to withstand the weight of the unit while running.

In order to reduce the transmission of vibrations to the supporting structures, fit shock absorbers in every fastening point. Rubber shock

absorbers are recommended for units installed on the ground, spring shock absorbers for units installed on roofs. Open spaces around the

unit must be provided for in order to allow for the passage of necessary airflow and in order to allow normal maintenance to be carried out

(as shown on general catalogues).

ATTENTION: in case two units have to be installed side by side, the distance of respect must be doubled.

NO

YES

YES

NO