MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 26 di 31

13

Start-Up Preliminary Procedures

13.1

Preliminary check

Before starting the unit, even only momentarily, all the machinery supplied by the chilled water, like the air handling units, pumps, etc.

have to be checked. The pump auxiliary contacts and the flow switch have to be connected to the control panel as indicated in the

electrical diagram. Before carrying out interventions on the valve regulations, loosen the relevant valve gland. Open the discharge valve of

the compressor. Open the liquid shutoff valve placed on the liquid line. Measure the suction pressure. If it is lower than 0.42 MPa jumper

and strain the solenoid valve on the liquid line. Bring the suction pressure to 0.45 MPa, then remove the jumper. Charge all the water

circuit progressively. Starts up the water pump of the evaporator with the calibration valve shut and then slowly open it.

Discharge the air from the high points of the water circuit and check the direction of the water flow. Carry out calibration of the flow by

using a measurer (if present or available) or by means of a combination of the readings of the manometers and the thermometers. In the

starting phase calibrate the valve on the pressure difference read on the manometers, carry out drainage of the tubes and then carry out

fine calibration on the temperature difference between the water in and the water out. The regulation is calibrated in the factory for water

in to the evaporator at 12°C and water out at 7°C. With the general switch open, check that the electrical connections are tightly clamped.

Check for any possible refrigerant leaks. Check that the electrical data on the label correspond to those of the mains supply. Check that the

thermal charge available is appropriate for starting.

13.2

Refrigerant seals control

Thermocold units are sent with the complete charge of refrigerant and are at a sufficient pressure to check the seal after installing. If the

system were not under pressure, blow refrigerants (vapour) into it until pressure is reached and look for leakage.

After having eliminated the leakage, the system has to be dehydrated with a vacuum pump up to at least 1mm Hg - absolute pressure (1

Torr o 133.3 Pa). This is the minimum recommended value to dehydrate the plant.

Dangers do not use the compressor to vacuum the system.

13.3

Refrigerant charge check

Thermocold units are supplied with a complete charge of refrigerant. If bubbles can be seen through the peephole with the compressor

running with a full charge and steadily, it means that the refrigerant charge is insufficient.

Danger While refrigerant is being added do not exclude any control system and let the water circulate in the evaporator to avoid the

formation of ice.

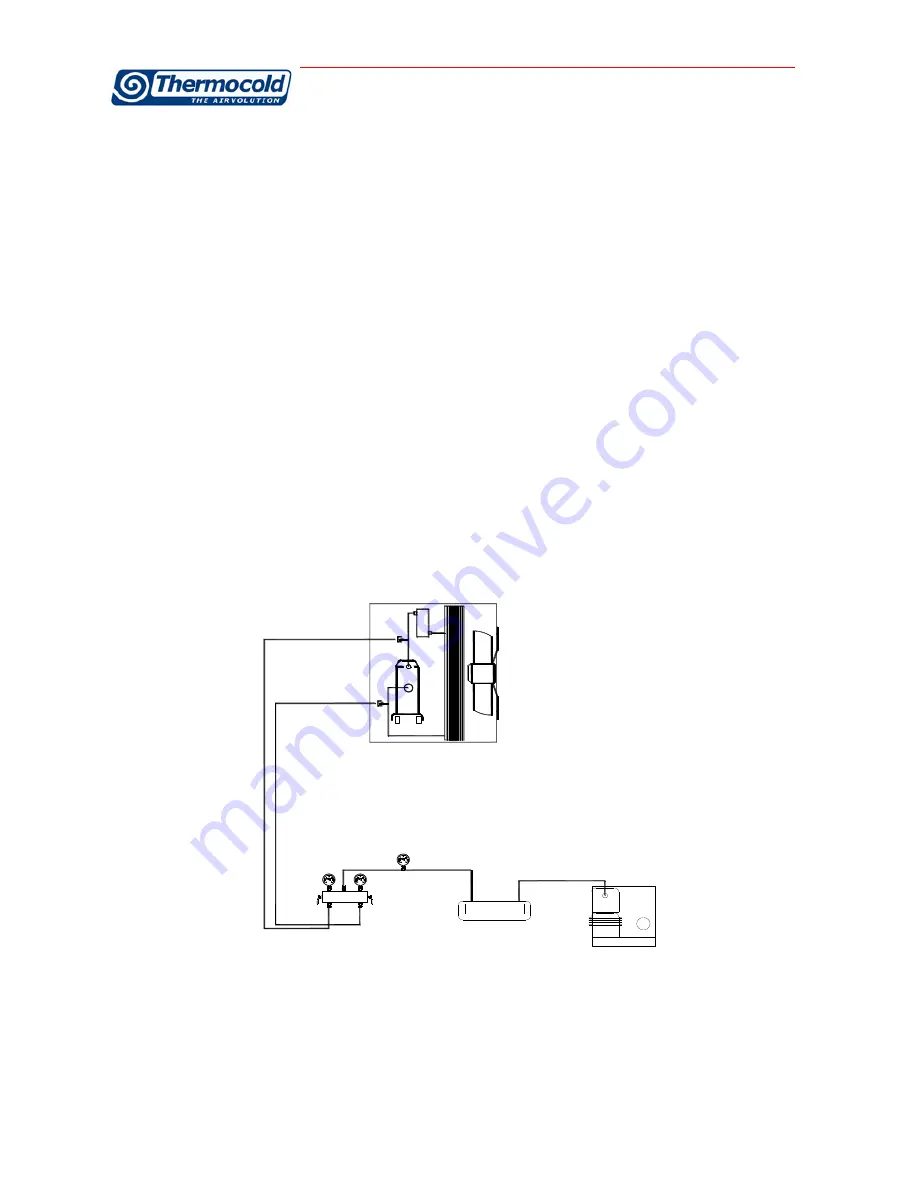

Cooling circuit diagram with connection to vacuum pump.

manometro

alta pressione

bassa pressione

manometro

vacuometro

pompa del vuoto

trappola olio

presa bassa pressione

presa alta pressione