MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 29 di 31

14.5

Power supply to the auxiliary circuit

The power supply to the auxiliary circuit is 24V for all the units. Connection to the power circuit is inside the panel and is carried out in the

factory. The compressor oil heaters, the protections against compressor over temperature and the cooling water safety indicator are

connected so as to always be operative, as long as the electrical panel is power supplied.

15

Maintenance

Maintenance operations are fundamental in order to keep the units running properly, both purely functional and energetically points of

view.

Every Thermocold unit comes with a logbook, in which the user or the person delegated to machine maintenance can keep all the required

notes, in order to keep a historical log of the Thermocold unit.

A lack of notes in the logbook could be considered proof of careless maintenance.

15.1

Sight check of the under pressure vessels state

The risks due to the pressure inside the circuit have benne eliminated or (when it is not possible) reduced by means of safety devices. It is

important to check periodically the status of these devices and to carry out the components inspections and replacement as follows.

Check at least once per year the under pressure vessels state.

It is important to check that the surface does not get rusty and that neither corrosion nor deformations are visible.

In case the superficial oxidisation and the corrosion are not properly controlled and stopped in time, cause a thickness reduction with a

consequent reduction of the vessel mechanical resistance.

Use antioxidant paint or products to protect.

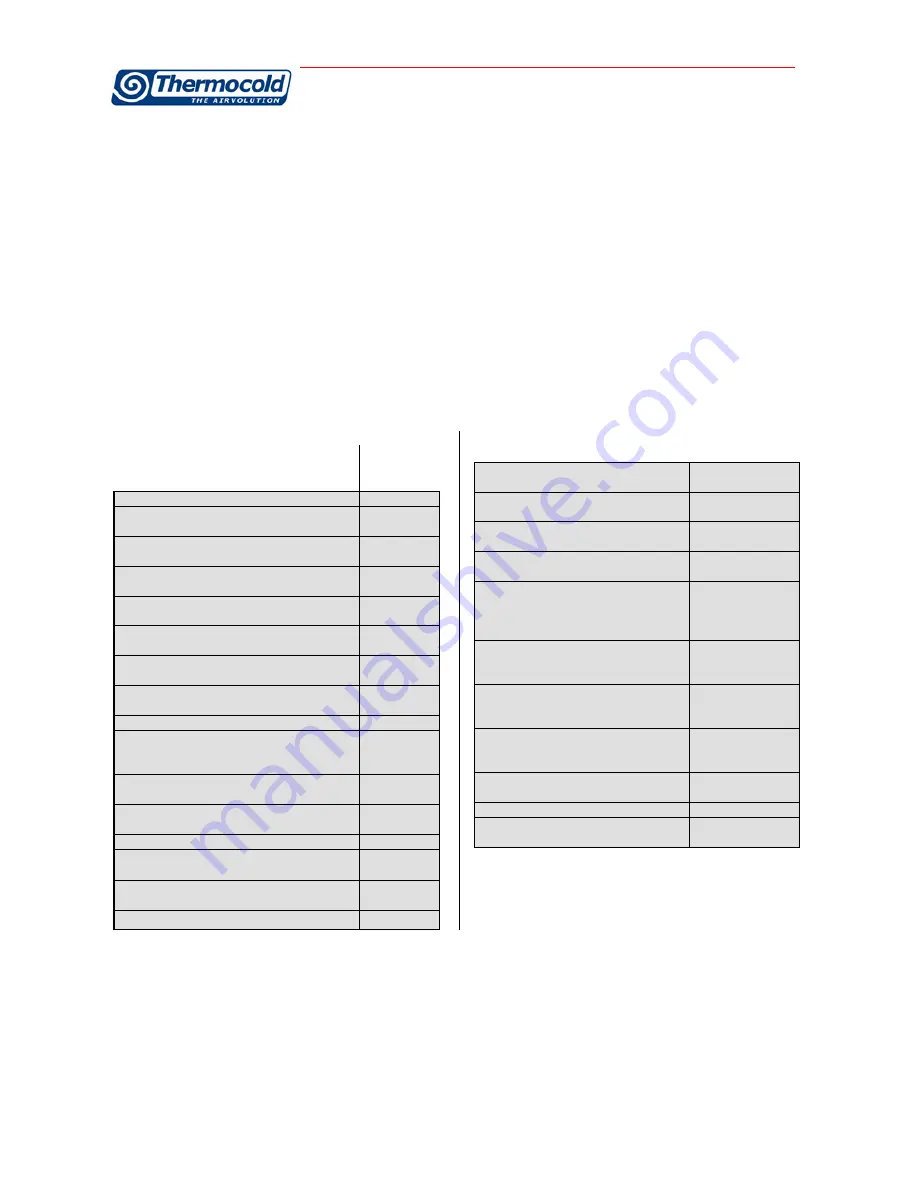

Description of the operations

Recommen

ded

frequency

Control of compressor oil level

monthly

Control of the suction temperature

(superheating)

monthly

Control of the hydraulic circuit water

filling

monthly

Control of electric absorption fan motors

and compressor

monthly

Control of power supply and auxiliary

power

monthly

Control of refrigerant charge through

liquid sight glass

monthly

Control of the state of the carter electric

heaters

monthly

Carrying out tightening of all the electrical

connections

monthly

coil cleaning

seasonal

Control of the functioning of the

compressor solenoid valves and liquid

line

Six-montly

Control of the setting of the regulation

and safety thermostat

Quarterly

Control of the state of the fan and

compressor contactors

Quarterly

Functional test of the evaporator heater

Quarterly

Noise control of the engine and fan

bearings

Six-montly

Pressure tank state checking

yearly

Cleanness control for coils and air-filters weekly

Further operations for units with centrifugal fans

Control of the cleanliness of the

discharge and circulation ducts

yearly

Control of the correct functioning of

possible dampers or inlets

Six-montly

Control of the lubrication of the

shaft bearings

Six-montly

Control of the pulley - engine and

pulley - fan alignment

seasonal

Control of the tension of the

transmission belts; if they are

excessively worn they should be

replaced

Quarterly

Check that the rotor is centred on

the shaft and that it does not touch

the Archimedean screw

Quarterly

Control of cleaning if necessary of

the fan rotor and Archimedean

screw

yearly

Control and if necessary tightening

of the blocking screws of the engine

pulley

Quarterly

Control of the presence of

excessive or unusual vibrations

Six-montly

Control of the fan joint seal - outlet

Six-montly

Control of the current absorption of

the three engine phases

Montly