Issue Date: 06.04.2021

Page 4 / 12

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Deutschland · tel: 02778/6960-0 · fax: -400 ·

LCF02-5DO_Datasheet_en.docx © 2021

»

FUNCTION DESCRIPTION

Communication Modbus

Communication-section

1..247

Factory default:

1

Address 0:

broadcast address

Communication-Interface:

RS485

Communication-Protocol:

Modbus-RTU

Baud Rate:

4800 bps / 9600 bps / 19200 bps / 38400 bps (optional)

Factory default:

9600 bps

Parity:

no parity / odd parity / straight parity (optional)

Factory default:

no parity

Data:

8 bit

Stop:

2 bit

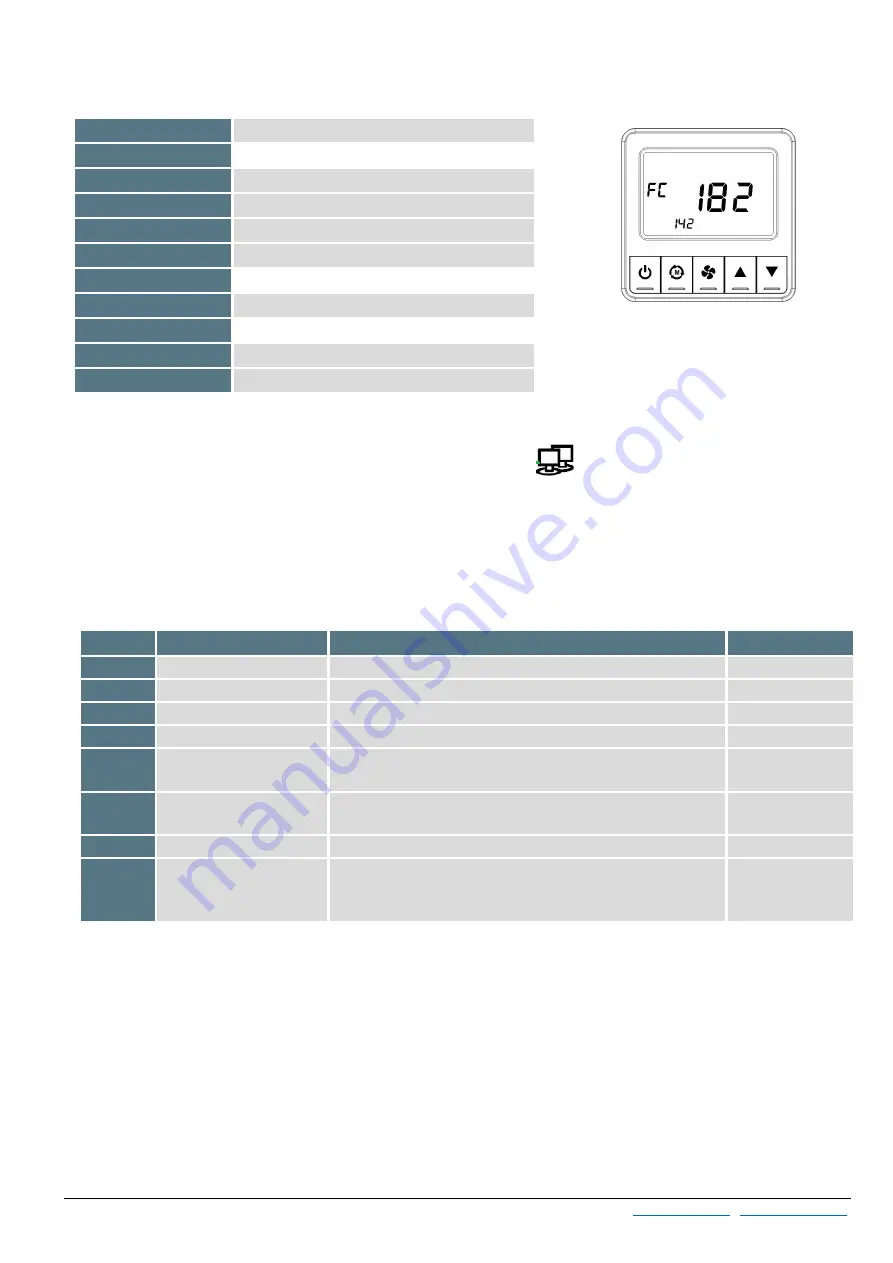

During device start-up the version and type number are displayed on the start screen for a short time.

While the fan coil thermostat is communicating via the bus, the communication symbol

starts flashing. If the device does not communicate

via the bus, the symbol will be disappear after 10 seconds.

Parameter table

To enter the parameter table, press the “Mode Key for more than 5s. Once the Display comes on, it will prompt for the password (default 987). The

password can be entered digit by digit. Each digit can be increased / decreased using the “▲”or “▼” keys. With the “Mode Key”

the next digit will

be selected.

Each parameter can be increased / decreased using the “▲”or “▼” keys. With the “Mode Key” the display will move on to the nex

t parameter.

Once the end of the table is reached the parameter setting will be exited to normal operation.

No.

Name of parameter

Parameter definition

Factory default

1

Modbus address

ID.1- ID.247

1

2

Baud rate

1 = 4800bps | 2 = 9600 | 3 = 19200 | 4 = 38400

2

3

Parity

0 = none | 1 = even | 2 = odd

0

4

Stop Bits

1 = 1 Stopbit | 2 = 2 Stopbits

2

5

Temperature Offset

Internal

Sensor

-5,0 K..+5,0 K

0

6

Temperature Offset

External Sensor

-5,0 K..+5,0 K

0

7

Piping system

0 = 2-pipe | 1 = 4-pipe

1

8

Reset to Factory Settings

Setting Parameter to 1 and press the Mode Key resets the device to

factory settings. Device stays in Parameter menu for Modbus

configuration

0

The Fancoil controller is designed for fan coil units with 2- or 4-pipe systems for heating and cooling. The selection of the fan coil system has to be

done via the parameter No. 7.

Heating/ cooling with 2-point-/ 3-point-controller

(Register address 0x0130)

In the case of temperature control, the 2-point controller only knows the switching states heating ON and heating OFF. The 3-point controller also

knows the switching state of cooling. Two - and three-point controller work with a hysteresis.

Heating/ cooling with PI-controller (PWM)

(Register address 0x0130)

The time response of the PI control loop depends on the control parameters xp for the proportional area and tn for the reset time of the integral

range. In case of an error, the P portion immediately changes the position value proportionally to the error variable, while the integral portion takes

effect after a certain time. The resulting actuating variable is output as a pulse-width-modulated signal directly to the outputs.