3.4

SYSTEM DIAGNOSTICS

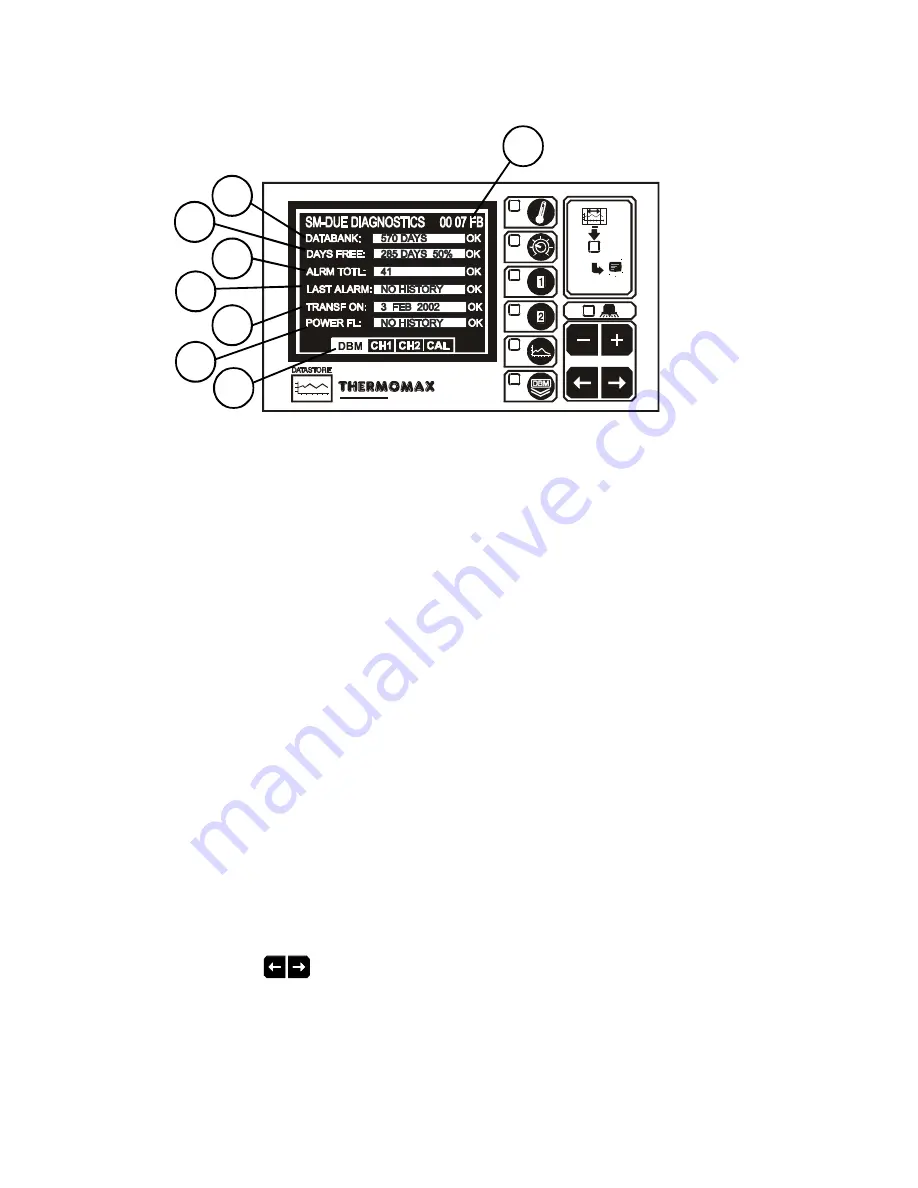

3.4.1 DATABANK DIAGNOSTICS SCREEN

SM DUE

1

This is the unique electronic signature of the SM DUE.

2

The DATABANK window shows the capacity of the internal databank. There

are two SM DUE options available:

(a) Recording frequency 5 minutes – Databank capacity 570 days

(approx. 1 ½ years - factory default)

(b) Recording frequency 10 minutes – Databank capacity 1128 days

(approx. 3 years)

3

The DAYS LEFT window shows the total number of days, and also the

total percentage of the databank, which have not yet been ‘used’.

4

The ALRM TOTL window shows the total number of alarm incidences

which have occurred in the current year.

5

The LAST ALRM window shows the last date on which an alarm condition

occurred.

6

The TRANSF ON window shows the date on which the contents of the

internal databank need to be transferred.

7

The POWER FL window shows the last date on which the power failed.

During a power fail situation this window will display the duration, in

minutes, of the power failure.

8

Diagnostics Screen Selection.

Use the

keys to move between one of four diagnostic screens:

- DBM: Databank Diagnostics Screen

(Ref. 3.4.1 above)

- CH1: Channel 1 Diagnostics Screen

(Ref. 3.4.2)

- CH2: Channel 2 Diagnostics Screen

(Ref. 3.4.2)

- CAL: Calibration Trimming Screen

(Ref. 3.4.3)

2

3

4

5

6

7

8

14

1