INSTALLATION PROCEDURES

3

2. Make heating cable allowances for valves, flanges, elbows

and supports as per the applicable drawings and table on

pages 2 and 3 of these installation procedures. See product

specifications sheet for heating cable minimum bend radius.

Temporary Installation

Proposed End-of-Circuit

Location

Proposed Power

Connection Location

Pipe Support

Cable Allowance for

In-Line Heat Sinks

Initial Installation . . .

1. Begin temporary installation at the proposed end-of-circuit

location and lay out heating circuit on the pipe, allowing ex-

tra cable for the power connection and for any splice loca-

tions. Refer to illustration below for temporary installation.

Installation on Fittings and Equipment . . .

1. Install heating cable in accordance with illustrations below.

Secure heating cable to piping using attachment tape.

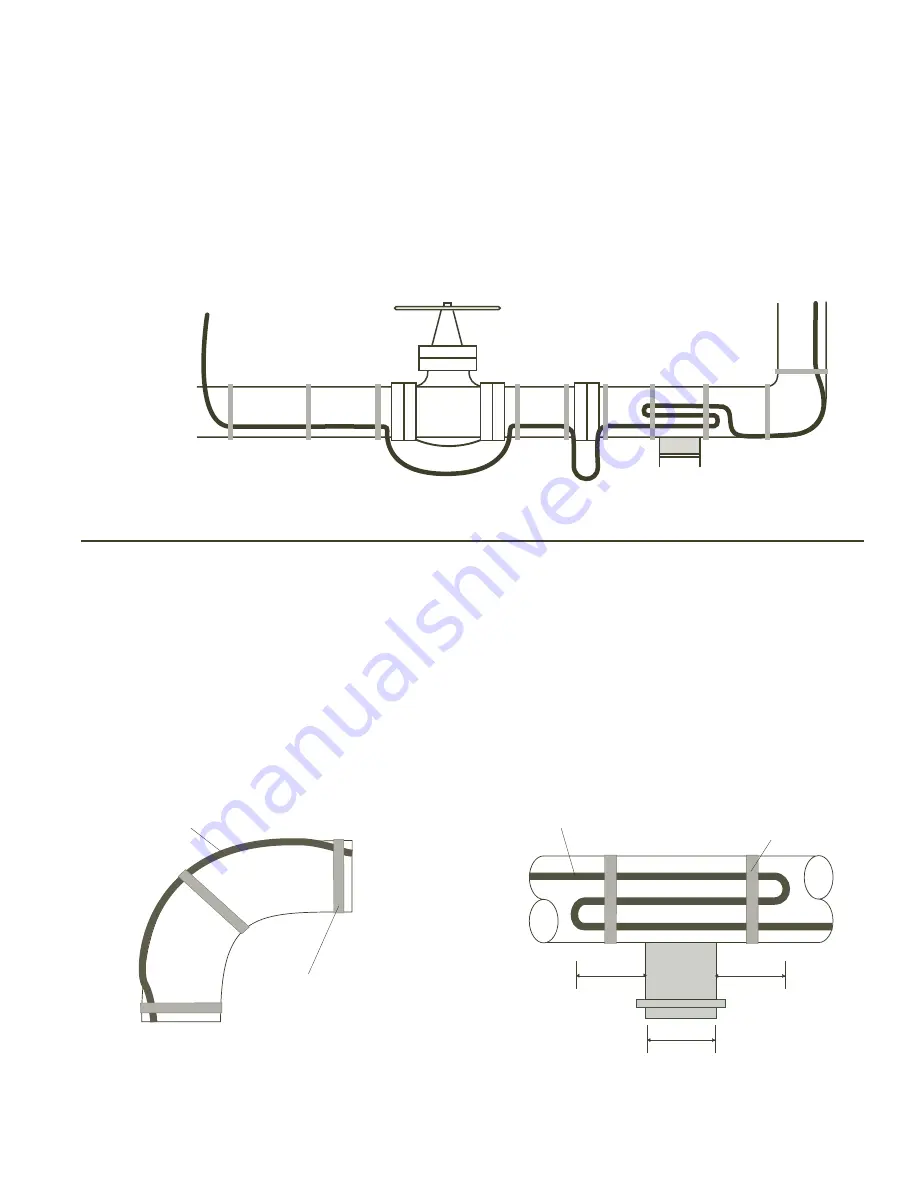

2. Elbows: Locate the cable on the outside radius of an elbow

to provide sufficient heat to compensate for the added pip-

ing material. Secure the cable to the pipe on each side of

the elbow with attachment tape.

Attachment Tape

(Typical)

Heating Cable

Pipe Elbow

Pipe Support

Support

Length

Attachment Tape

(Typical)

Heating Cable

3” Min.

(8 cm)

3” Min.

(8 cm)

3. Pipe Supports: Insulated pipe supports require no additional

heating cable. For uninsulated supports, allow two times the

length of the pipe support plus an additional 15” (40 cm) of

heating cable.