3

The Terminator ZP/FAK-1 Split Bulkhead Entry Kit is designed to

make a waterproof seal over the end of TubeTrace and terminate

Thermon electric heat trace in an approved junction box. Review

Instructions prior to installation. Kit will make one connection.

INSTALLATION PROCEDURES

Installation Precautions

• To minimize the potential for arcing on electrical heat tracing

and fire caused by product damage or improper installation,

use ground-fault protection.

• Installation must comply with Thermon requirements and be

installed in accordance with any applicable national and local

codes.

• Component approvals and performance ratings are based on

the use of Thermon specified parts only. User supplied power

connection fittings must be listed or certified for intended use.

• De-energize all power sources before opening enclosure.

• Keep ends of bundles, heat tracing and kit components dry

before and during installation.

• Individuals installing these products are responsible for

complying with all applicable safety and health guidelines.

Proper personal protective equipment, or PPE, should be

utilized during installation. Contact Thermon if you have any

additional questions.

Terminator ZP Certifications/Approvals

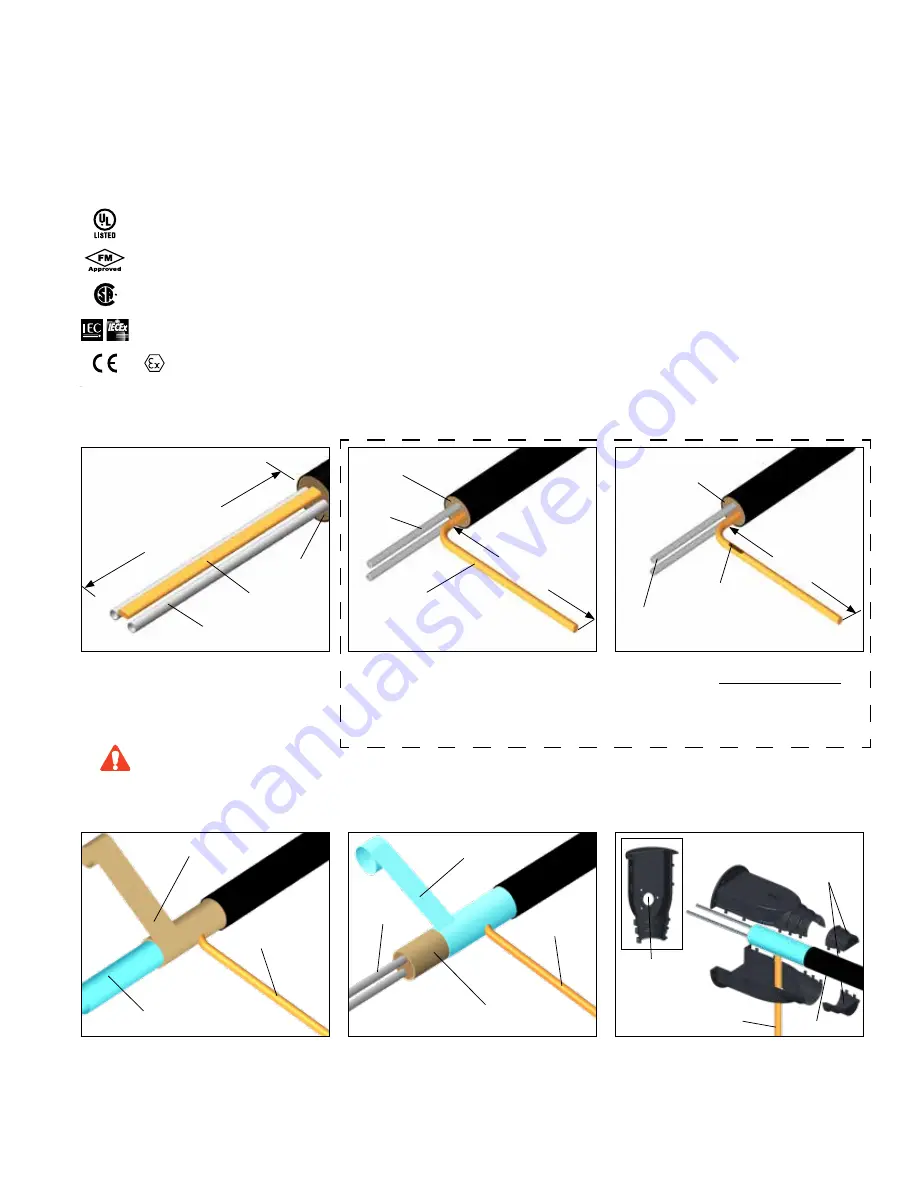

2.

Trim heat tracing to within 305 mm–381 mm

(12”–15”) of the end of the insulation. If

self regulating heat trace proceed to step

3. For Zone-type heat trace continue with

indentification of bus connection on step 2a.

1.

Remove outer jacket and insulation from tubing

bundle as included from end of the tubing

bundle. Ensure sufficient heat trace is available

for electrical connection. See instructions

included with heat trace PETK kit (purchased

separately).

2a.

Strip back bundle insulation 38 mm (1-1/2”)

to 76 mm (3”) beyond bus connection

heat

tracing. If bus connection indentation is less

than 305 mm–381 mm (12”–15”) from end of

the heat tracing, proceed stripping the bundle

insulation to the next indentation.

3.

Wrap tubes and heat tracing with pass of heat

reflective tape (25% overlap). Then wrap with 3

passes of glass fiber tape (50% overlap), or until

fiber tape is equal to original bundle insulation

thickness.

4.

Complete with additional passes of heat

reflective tape.

Trim as Required

for Connection

Tubing Bundle

Tubing

Heat Tracing

Tubing

Self-Regulating Heat Tracing

Heat Tracing

305 mm–381 mm

(12”–15”)

Insulation

Zone Type Heat Tracing

Tubing

Bus Connection

Indentations

(Zone Heater Only)

305 mm–381 mm

(12”–15”)

Insulation

Glass Fiber Tape

Heat Reflective Tape

Heat Tracing

5.

Cut FAK-1 top and base ends to match outside

diameter of tubing bundle and remove end

pieces.

Heat Reflective Tape

Glass Fiber Tape

Heat Tracing

Tubing

CAUTION

(Found on TubeTrace SE/ME bundles)

Do not cut or damage the heat

trace or sampling tube.

Tubing Bundle

Cut and Remove

to fit

Heat Tracing

Field Drilled

(By Others)

IP66/Type 4X -60°C ≤ Ta ≤ +55°C

Listed Heat Tracing Cable System 137M

Ordinary & Hazardous Locations

Class I, Division 2, Groups A, B, C, & D

Class II, Division 2, Groups F & G, Class III

Class I, Zone 1, AEx eb IIC T4-T6

09.2238691,-G,-S, Ex e IIC T4-T6

FMG 10.0022X Ex eb IIC T4-T6, Ex tb IIIC T135°C-T85°C

1725 II 2 GD Ex eb IIC T4-T6, Ex tb IIIC T135°C-T85°C FM 10ATEX0058X