6. Min. temp. heating watter

(factory setting 30°C)

States the lower limit of the requested temperature for

heating water calculated by the thermostat for when

the heating can start. This constant prevents

redundant activation of the boiler

.

Optional range from

5.0 °C to 50.0°C (by 1.0°C).

7. Max. temp. heating watter

(factory setting 70°C)

States the upper limit of the requested temperature of the heating

water calculated by the thermostat which the boiler must not

exceed. Difference between the minimum and ten maximum

temperature must be greater than 8°C.

Optional range from

13.0 °C to 85.0°C (by 1.0°C).

Turn the “ “ button to set the minumum temperature

of the heating water and confirm with the ” “ button.

Constant No. 7 automatically appears.

Turn the “ “ button to set the maximum temperature

of the heating water and confirm with the ” “ button.

Constant No. 8 automatically appears.

Pr

ogr

amming and

setting par

amet

e

rs

Main menu

Setting

4

Constants

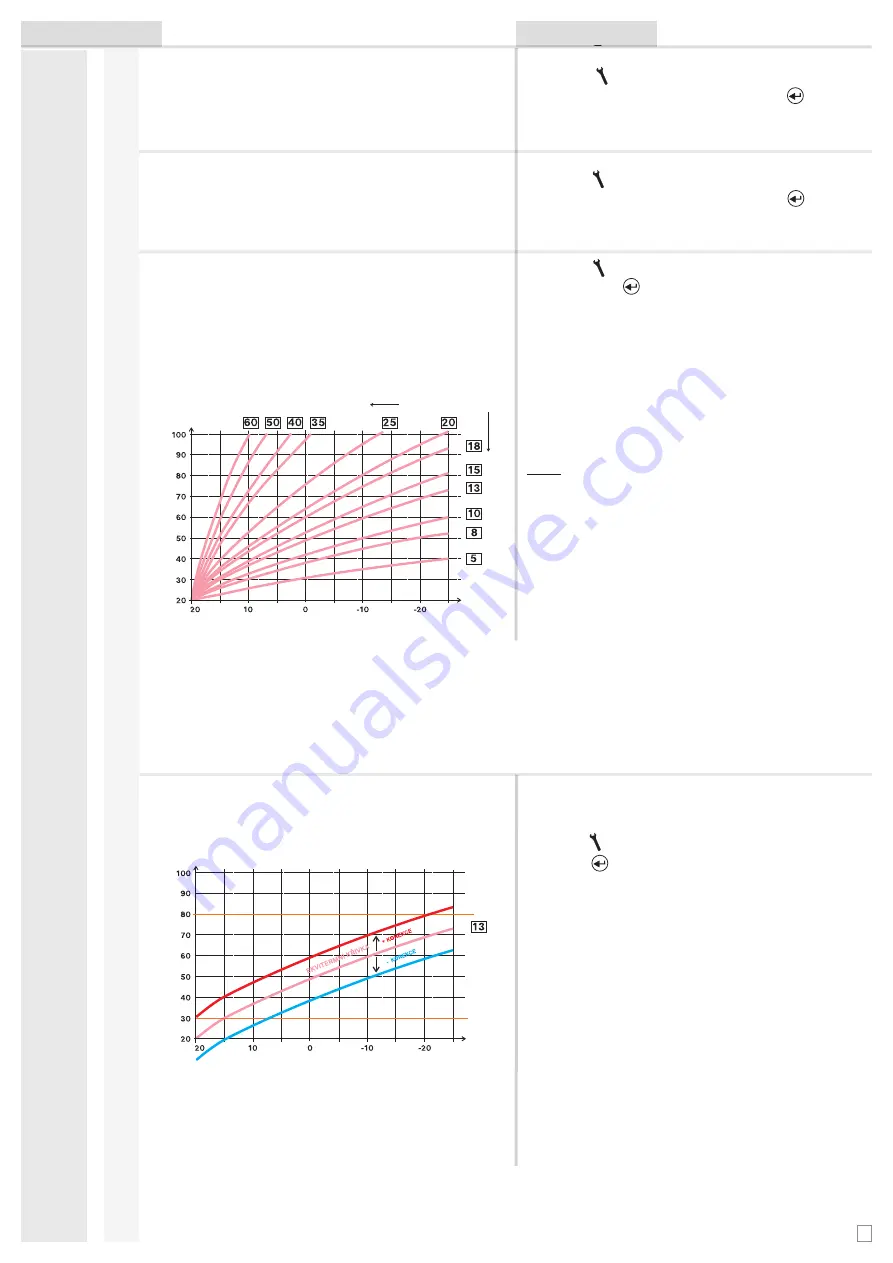

8. Number heating curve

(factory setting “Room control”)

Selection of the type of regulation.

Room control = PI regulation (according to the

inside temperature).

The thermostat heats up

depending on the temperature in the reference room.

It is necessary to set constants 11 and 12!

1 - 60 = equithermal regulation,

number 1 to 60

corresponds to the requested heating curve (see below)

It is recommended to select equithermal regulation for large buildings where it is not possible to select a reference room. The principle of

equithermal regulation is optimising the temperature of the water for the heating system depending on the outdoor temperature.

The mentioned equithermal curves express this dependence (for a requested room temperature of20°C), according to which it is possible to select the

requested temperature of the water in the heating system. The thermostat calculates the temperature of heating water according to the selected

equithermal curve which is consequently sent to the boiler. Then the boiler regulates the temperature of heating water to the requested value.

It is necessary to select the slope of the curve according to the heating system to prevent permanent over or under heating of the building.

The selection of the correct curve for the stated system is a long-term issue and it is necessary to test the system at various outdoor temperatures! It is

recommended to modify the indoor temperature in the rooms, e.g. regulation by thermostat heads.

The water temperature in the heating system is

restricted by minimum and maximum limits which are set in constants No. 6 and 7! During this regulation, the outdoor sensor must always be

connected to the boiler!

Turn the “ “ button to select the type of regulation

and press the ” “ button to confirmation.

In the case of selection of equithermal regulation follow

the instructions under the graph with the heating

curves

.

If selecting a requested room temperature of other than

20 °C, the thermostat calculates the automatic shift of the

curve according to the following equation where the

coefficient is 1:

shift = (requested temper. - 20) * coefficient

Note.: the most frequently used curve under our conditions

is 9-11 for low-temperature systems and 15-17 for traditional

heating systems.

After selection of the optimal heating curve and the

confirmation, there is a shift to constant No. 9.

In the case of option PI regulation

constants No. 9, 10 are

skipped and constant No.11 is automatically displayed for

further setting of the Pl regulation.

9. Parallel displac. h.c.

0.5 to 10.0 =manual correction according to the

coefficient

, used if the temperature is not

according to your requirements (by 0.5).

In the case of this regulation, the heating curve is automatically corrected depending on the outdoor temperature, as well as

the actual temperature in the reference room where the thermostat is located.

This enables to achieve higher thermal comfort in

the heated area, optimal operation of the heating system and greater savings! During this regulation, the sensor must always be

connected to the boiler and

constant No. 9 must be set to „AUTO”

!

AUTO= automatic correction

, according to the

indoor temperature measured in the reference

room. It is possible to use this option after the

correctly selected equithermal curve!

Example

describes the option for equithermal curve No. 13

(pink) and the calculated correction with the coefficient 2.5

(for requested room temperatures of 24 °C and 16 °C). The

optimal setting of the system is achieved when the water tem-

perature of the heating system is regulated according to the

actual outdoor temperature.

In the case of setting the equithermal regulation, it is possible

to select manual correction of the shift of the curve or the

automatic correction according to the indoor temperature.

Turn the “ “ button to set the correction for the curve and

press the ” “ button to confirm.

In the case of

manual correction

set the shift coefficient

for the heating curve when at various requested tempera-

tures in the reference room, regulation of the heating water

will be reached according to the actual outdoor tempera-

ture (for the formula, see constant No. 8).

After setting and confirmation, there is the automatic

transfer to constant No. 10.

In the case of option

automatic correction according

to the indoor temperature, constants No. 10, 11 and

13 must be set.

Omezení max. teploty

vody top. sys. (Konst. 7)

Omezení min. teploty

vody top. sys. (Konst. 6)

external sensor

temperature [°C]

re

quir

ed t

e

mper

atur

e of

heating syst

em [°C]

external sensor

temperature [°C]

re

quir

ed t

e

mper

atur

e of

heating syst

em [°C]

designation of curves