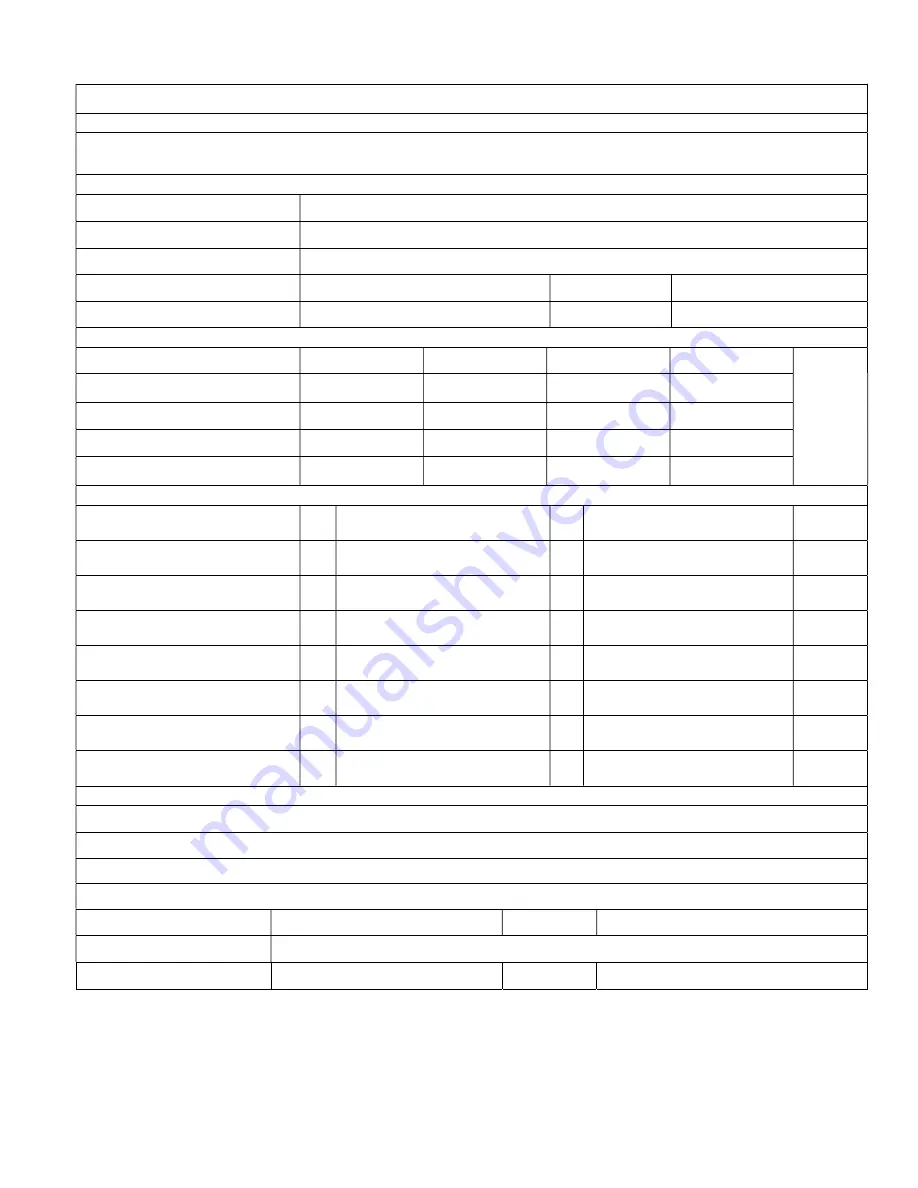

ICE RINK DEFOGGER

Start-up Report & Warranty Registration

Warranty void unless completed and a copy returned to Thermoplus Air immediately after start-

up!

Installation Name

Installation Address

Thermoplus Air Representative

Model #

Serial #

Compressor Serial #

Belt Size

Electrical power

L1-L2

L2-L3

L1-L3

Nameplate

Blower amperage

Blower voltage

Compressor amperage

Compressor voltage

Adequate service access

provided?

□

Main blower connected?

□

Discharge duct with louvers

installed?

□

Air supply outlets as per

installation drawings?

□

Wire connections checked for

tightness?

□

Air flow and blower speed

adjusted?

□

Units level and vibration

isolated?

□

Drain connection tested and

P-trap filled?

□

Air entering temperature

____°F

Minimum 4 feet Clearance on

return side of units?

□

Compressor service valves

opened?

□

Air leaving temperature

____°F

Condensate drain connected?

□

Clean air filters installed?

□

Air leaving evaporator

temperature

____°F

Main disconnect switch

installed?

□

Coils are clean?

□

Refrigerant charge OK?

□

Remote on/off switch (double

pole) installed?

□

On/Off switch on unit in "on"

position?

□

Compressor discharge

temperature

____°F

Enclosure temperature

between 35°F and 80°F?

□

Crankcase heater working?

□

Supply air directed properly

□

Comments:

Form completed by

Signature

Company Name

Date

Telephone ( )