4

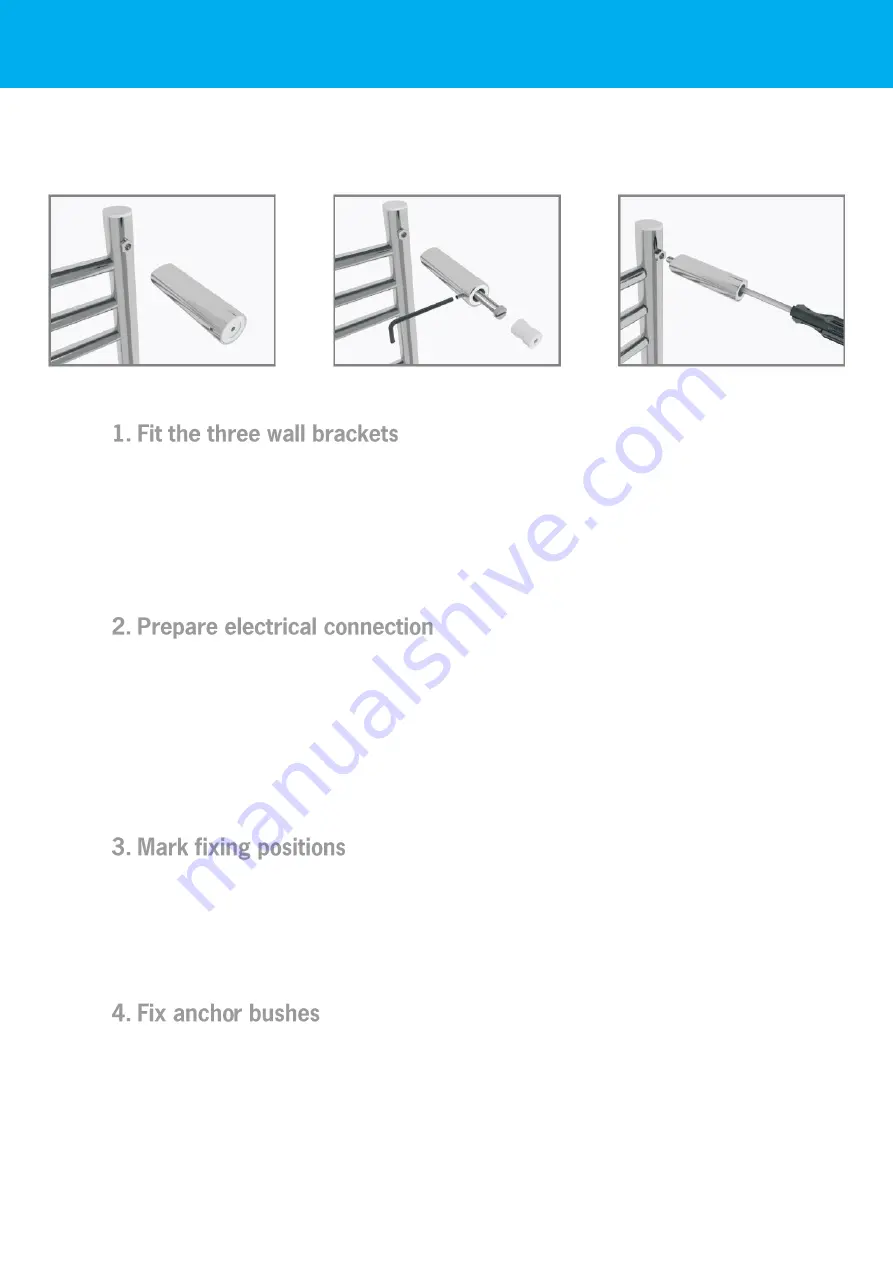

To fit all three wall bracket tubes to the nuts on the back of the towel rail,

partially undo the grub screw in each stainless steel tube using the allan key

provided (Fig.1). Drop the anchor bush out of the tube (Fig.2). Using a flat

head screwdriver, attach the bracket tube to the nut taking care not to over-

tighten the set screw. Ensure that the hole for the grub screw is facing down,

out of normal view (Fig.3).

If the electrical connection is to be in a standard round junction box, place

the metal disc of the element cover onto the plastic wall plate. Align the

holes in the disc to those of the junction box and using the two 5mm x

40mm machine screws, attach the metal disc and plastic plate to the

junction box. Should the electrical connection wires exit directly from a

conduit, guide the wiring through the centre of the metal disc and mark the

two holes on the wall for drilling.

Ensure that the rail is straight and level before carefully marking the outside

circumference of the three tubes against the wall. Remove the rail from the

wall. In order to avoid a hazard for very young children, this appliance should

be installed so that the lowest heated towel rail is at least 600mm above

the floor.

Place the centre finder within the pencilled circle and mark the centre spot

for drilling. Drill the holes to the correct depth using a 6mm masonry drill

and insert the plastic wall plugs. Attach the 3 anchor bushes firmly to the

wall using the 10 x 50 fixing screws.

Installation Steps

Fig.1

Fig.2

Fig.3

The Thermorail models in this guide need to be hard wired and the wiring is

supplied connected at the bottom right.

Fig. 1

Fig. 2

Fig. 3