Installation, use and maintenance guide

ARDHEA EVO5

– ARDHEA-F EVO5

Page

28

ENG

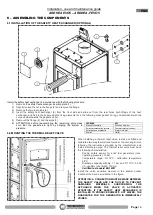

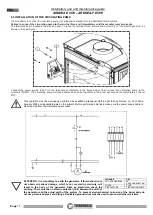

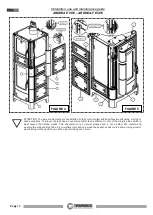

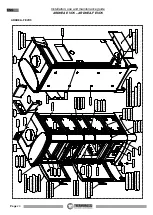

11 - SPARE PARTS

ARDHEA EVO5

6001

033

6

Gu

ar

ni

zi

on

e

70

01

302

4 P

or

ta

com

pl

et

a

80

01

16

41

P

or

ta

gh

is

a

6001

152

6

Ve

tro

por

ta

6001

034

1 G

uar

n.

por

ta-

tel

ai

o

6001

034

1 G

uar

n.

ve

tr

o-p

or

ta

600052

54

6001

158

3

6001

28

05

Te

rm

ostato

ar

ia

6001

27*9

9 P

er

no

p

er

ter

m

ostato

ar

ia

70

01

28

03

70

01

31

21

6001

28

22

70

01

304

8

6001

18

01

B

EI

GE

70

01

27

87

70

01

302

5

70

01

3009

6001

26

98

B

ei

ge

70

01

303

2

70

01

29

97

DX

70

01

3000

S

X

70

01

3053

Atti

zz

atoi

o

6000

42

08

Ganci

o a

r

asch

iettia

sch

ie

tt

o 6

0004

209

6001

2704

B

ei

ge

6001

29

01

Bei

ge

60004

22

6

6001

28

09

60009

16

1

Sp

ia

Verd

e

70

01

175

4 M

an

ig

lia

6001

26

70 S

em

ig

usci

o sup

.

6001

26

71

S

em

ig

uscio

i

nf

.

6001

26

82

C

UO

IO

6001

18

00 RO

SS

O

6001

26

97

C

uo

io

6001

26

96

Ro

sso

6001

2701

B

ei

ge

6001

2700

Cu

oi

o

6001

26

99

Ro

sso

6001

29

03

Ro

sso

6001

2703

C

uo

io

6001

2702 R

os

so

Scam

bi

ato

re

di

si

cur

ez

za

6001

2705

60004

234

M

or

setti

er

a

60007

10

2 T

er

m

os

tato

6

0°

C.

6001

29

02

C

uo

io

70

01

303

7

6001

17

61

70

01

155

5

Ki

t

ch

ius

ur

a

fl

ang

ia

fo

ro

ser

pe

ntino

70

01

155

4 k

it ch

iu

su

ra

ta

pp

i f

ori se

rp

entin

o

A

R

D

H

E

A

.p

d

f

09

/

0

7

/

2

02

1

70

01

303

3

70

01

3007

70

01

3004

70

01

3001

80

01

16

40F

T

el

ai

o

gh

isa

6001

35

72 BI

AN

CO

70

01

85

10 Bi

anco

70

01

85

12

B

ia

nco

6001

35

80

B

ian

co

70

01

85

13

Bi

anco

70

031

25

4

70

01

31

20

70

031

25

3

70

031

25

2