pg. 19

Before connecting the central heating cooker to the flue outlet it is advisable to check the flue outlet draft. This operation can be carried out

using a draft gauge: the vacuum must measure 1.5 - 2 mm water gauge.

We recommend having an expert technician control the flue outlet at least once a year.

Poor draft causes poor combustion which results in a reduced power.

It is important to be aware of the fact that in terms of correct functioning and safe usage the flue outlet is just as important as the central heating

cooker. The smoke pipes must be connected to the flue outlet in the same room in which the heater is installed or in an adjacent room and must

satisfy the following requirements:

be airtight and be capable of resisting normal mechanical stress, heat and the action of the combustion products and condensate over long

periods of time. The temperature of the gases, at any point in the channel, must be above dew point;

the joints must be sealed tight; if materials are used for this purpose they must be capable of resisting high temperatures;

be in full view, easily accessed for removal and installed in such a way as to be capable of resisting normal thermal expansion;

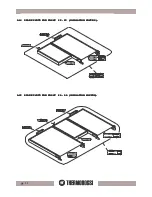

be installed in such a way that end of the tube with the smaller diameter faces the smoke vent and the end with the larger diameter faces the

flue outlet

have a horizontal run with a minimum upward slope of 3-5% (3-5 cm for each metre of tube ). The horizontal-sloped part must not be longer than

1/4 of the height of the flue outlet, and in any case must have a maximum length of 2.5m;

have no more than 3 changes of direction, including the flue outlet connector, and with internal corners that are a minimum of 90°. The changes

of direction must only be made with curved elements;

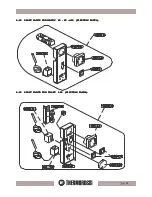

have (as described in the figure above) the axis of the female end perpendicular to the opposite wall of the flue outlet, without protruding into the

pipe;

Have, along its entire length, a section which is equal to or greater than that of the appliance’s exhaust tube fitting;

Have no shut off devices ( damper): if devices such as these are already installed they must be eliminated.

The previous chapter does not replace UNI 7129/92 and UNI 10683/98 to which it makes reference. The qualified installer

must in any case be fully aware of this standard and its amending versions.

YES NO

7 . 4

7 . 4

7 . 4

7 . 4

7 . 4

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION T

T

T

T

TO

O

O

O

O THE FL

THE FL

THE FL

THE FL

THE FLUE OUTLET

UE OUTLET

UE OUTLET

UE OUTLET

UE OUTLET

7 . 3

7 . 3

7 . 3

7 . 3

7 . 3

VENTILA

VENTILA

VENTILA

VENTILA

VENTILATION OF

TION OF

TION OF

TION OF

TION OF THE R

THE R

THE R

THE R

THE ROOMS

OOMS

OOMS

OOMS

OOMS

It is essential for the room in which the appliance is installed to be well-ventilated, also to guarantee secondary air for combustion in the central

heating cooker.

The natural air flow occurs directly through permanent apertures to the outside made in the walls of the room, or by means of single or multiple

ventilation ducting.

The ventilating air must come from outside and if possible, away from sources of pollution. Indirect ventilation is also allowed by taking in air from

rooms adjacent the one where the heater is installed taking into account all the warnings and limitations specified below.

•The apertures in the walls must comply with the following requirements:

- -have an unobstructed section of at least 6cm² for each Kw of installed thermal power, with a minimum limit of 100cm²;

- be made in such a way that the vent openings, both on the inside and outside of the wall, cannot be obstructed;

- be protected with grills or similar systems in order not to reduce the section described above;

- be situated at floor-level.

The air flow can also be obtained from an adjacent room as long as:

- the adjacent room is equipped with direct ventilation in compliance with the points described above;

- in the room to be ventilated the installed appliances are only connected to one flue outlet;

- the adjacent room is not used as a bedroom or a common area of the building;

- the adjacent room is not a room with a fire hazard, such as storage sheds, garages, combustible material store rooms, etc...;

- the adjacent room does not become a vacuum compared to the room to be ventilated due to an opposite draught effect;

- the air flow from the adjacent room to the room to be ventilated is unobstructed through the permanent apertures having an overall net section

of no less than that indicated above. These apertures can be obtained by enlarging the space between the door and the floor.