Installation, use and maintenance guide

COMPACT S22

–S26–S32 EVO5

Page

42

ENG

9 – SMOKE DISCHARGE TUBE AND VENTILATION OF THE ROOMS

9.1 FOREWORD

Due to the frequent accidents caused by poor functioning of flue outlets installed in private dwellings, we have

prepared the following paragraph to assist the installer in his inspection of the parts concerned with eliminating the

gases produced by combustion.

The smoke outlet must be fitted in compliance with standard UNI 7129/92, UNI 10683 and EN 14785 and it must

observe the reference values laid down in the standard, in particular, the outlet must comply with fire prevention

regulations.

It is important to carefully follow the instructions set out below: failure to observe these instructions could

cause serious damage to the product, to the system, to objects and to persons using the generator.

9.2 ROOM VENTILATION

ATTENTION: the presence of extraction fans or similar appliances, if operating in the same room or space in which

the product is installed, could cause problems for the correct operation of the product.

ATTENTION: do not obstruct the vents or the air inlets on the appliance.

The room where the appliance is installed must have a good air flow to guarantee air for the appliance for the combustion process

and for ventilation of the room. The natural air flow must take place directly through permanent openings on the outer walls or

through single or multiple ventilation ducting (paragraph 9.2.1).

The ventilating air must come from outside and if possible, away from sources of pollution. The openings in the walls must comply

with the following conditions:

• have an unobstructed section of at least 6cm² for each Kw of installed thermal power, with a minimum limit of 100cm²;

• be made in such a way that the vent openings, both on the inside and outside of the wall, cannot be obstructed;

• be protected with grills or similar systems that do not reduce the opening section indicated above;

• be situated at a height near floor level and they must not obstruct the correct operation of the combustion product discharge

devices; if this position is not possible the section of the ventilation openings must be enlarged by at least 50%.

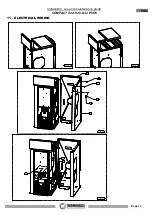

9.2.1 VENTILATION FROM ADJOINING ROOMS

The air flow can also be obtained from an adjoining room as long as:

• the adjoining room is equipped with direct ventilation in compliance with the paragraphs described above;

• only appliances connected to the exhaust pipe are installed in the room that is ventilated;

• the adjoining room is not used as a bedroom or a common area of the building;

• the adjacent room is not a room with a fire hazard, such as storage sheds, garages, combustible material store rooms, etc...;

• the adjoining room does not become a vacuum compared to the room to be ventilated due to a reverse draught effect (the reverse

draught can be caused by the presence in the room of either another heating appliance running on any type of fuel, a fireplace, or

any suction device, which have not been provided with an air intake)

• the air flow from the adjoining room to the room to be ventilated is unobstructed through the permanent apertures having an

overall net section of no less than that indicated above. These apertures can be obtained by enlarging the space between the door

and the floor.

9.2.2 SINGLE OR MULTIPLE VENTILATION DUCTING

If the combustion air is supplied through pipes, the available draught, produced by the installed appliance in use and by the

corresponding combustion product evacuation system, must be greater than the sum of the resistance offered by the pipes

(frictional resistance, resistance due to direction changes, cross-sectional restrictions, etc...).

The single ventilation pipes can be vertically and horizontally oriented: the length of the horizontal sections must be reduced to a

minimum.

The connectors between pipes with different orientations must not have any reduced cross-sections with sharp bends.

The angle of connection between the axes of two successive pipes must not be less than 90°.

For combustion air supplied through branched pipes, the sum of the resistance offered by the pipes (frictional resistance, resistance

due to direction changes, cross-sectional restrictions, etc....) can be a maximum of 10% of the available draught, produced by the

various appliances in use installed on the various floors and by the combustion product evacuation system.

The branched ventilation pipes must be vertically-oriented with an uphill run.

The inlet vent to the room to be ventilated must be located down low and in a position where it does not interfere with the d ischarge

of combustion products and must be protected by a grill or similar device.

9.3 SMOKE OUTLET

The smoke channel, the exhaust pipe, chimney and flue outlet (defined as the system for the evacuation of

combustion products), are parts of the heating system and they must comply with the legislative requirements of the

Ministerial Decree DM 37/08 (ex Italian Law 46/90) and to the applicable specific installation regulations, according to

the type of fuel. Fireplaces, stoves and barbecues must not be installed in locations where gas appliances type A and

type B are present and operating (for the classification see UNI 10642 and UNI 719). The connection between the

appliance and the flue outlet must only receive exhaust from one heat generator.