pg. 19

9.2

9.2

9.2

9.2

9.2

SMOKE OUTLET

SMOKE OUTLET

SMOKE OUTLET

SMOKE OUTLET

SMOKE OUTLET

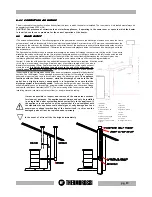

•The smoke exhaust shown in the following figures is the best solution to ensure the discharge of smoke even when the fan is

not operational, such as for example if there is an electrical power failure. A minimum drop of 1.5 metres is required between the

T terminal on the outside of the building and the outlet at the back of the appliance, to ensure that residual combustion smoke is

discharged in the case described above (Otherwise the residues would stagnate inside the firebox and be discharged out to the

free atmosphere).

The figures below illustrate the best solution for discharging the smoke out through the roof or into the flue outlet. If you opt to

discharge the smoke out through the roof it is important to operate as shown in the figure below on the left. Insert a union tee with

inspection cap, connecting brackets suitable for the height of the flue outlet, flashing that crosses the roof and chimney cap

to protect against bad weather conditions. If you decide to use a classic masonry outlet see the diagram below on

the right. A union tee with inspection cap and suitable supporting brackets are required. If the flue outlet

is too big we recommend inserting a stainless steel or porcelain-coated steel tube with a

diameter not exceeding 150mm. Seal area where the inlet and outlet part of the smoke exhaust

meets the wall. It is strictly forbidden to apply mesh to the end of the outlet tube , as

it could cause the heater to malfunction If the smoke tube is installed in a fixed position

it is advisable to provide inspection openings for clean-out purposes especially in the horizontal

sections. See the diagram. These openings are essential to allow for the removal of ash and

unburned products which tend to accumulate along the discharge path. The appliance

functions with the firebox in a vacuum, while the discharge of smoke to the flue

outlet has a slight pressure, consequently it is imperative to ensure that the

discharge system is hermetically sealed. The smoke discharge tube must be made from

suitable materials such as for example: porcelain-coated steel tubes, and the various fittings

sealed with red silicone (resistant to 350°C). The outer casing of the tube must be made with

insulating material (mineral wool, ceramic fiber) or use pre-insulated tubing.

In the event of a fire call the fire brigade immediately.

9 . 1 . 1

9 . 1 . 1

9 . 1 . 1

9 . 1 . 1

9 . 1 . 1

COMB

COMB

COMB

COMB

COMBUSTION

USTION

USTION

USTION

USTION AIR INT

AIR INT

AIR INT

AIR INT

AIR INTAKE

AKE

AKE

AKE

AKE

The air required for combustion is taken directly from the room in which the heater is installed. The room where it is installed must always be

adequately ventilated (1300 m3/h) .

CAUTION: The presence of extraction fans or similar appliances, if operating in the same room or space in which the heater

is installed, could cause problems for the correct operation of the heater.

K E Y

Inspection

Slope 3-5%

Height more than 4m

Internal

External

Rain protection

Cover slab

Watertight steel sheet

It must be possible to inspect and remove all the smoke tube sections

for clean-out purposes. The appliance must always and only be installed

in a single flue outlet system dedicated exclusively to the appliance. If

the appliance is connected to a flue system that is non-compliant with

the standards the appliance could show signs of early damage due to an

anomalous continual overheating of the heater itself : in this case the

damaged parts will not be replaced under warranty.

LEGENDA

Ispezione

Pendenza 3-5%

Altezza superiore a 4m

Interno

Esterno

Protezione dalla pioggia

Lastra di copertura

Lamiera di acciaio a tenuta

stagna

Summary of Contents for ECOTHERM 5000

Page 16: ...pg 16 ...

Page 17: ...pg 17 ...