pg. XIII

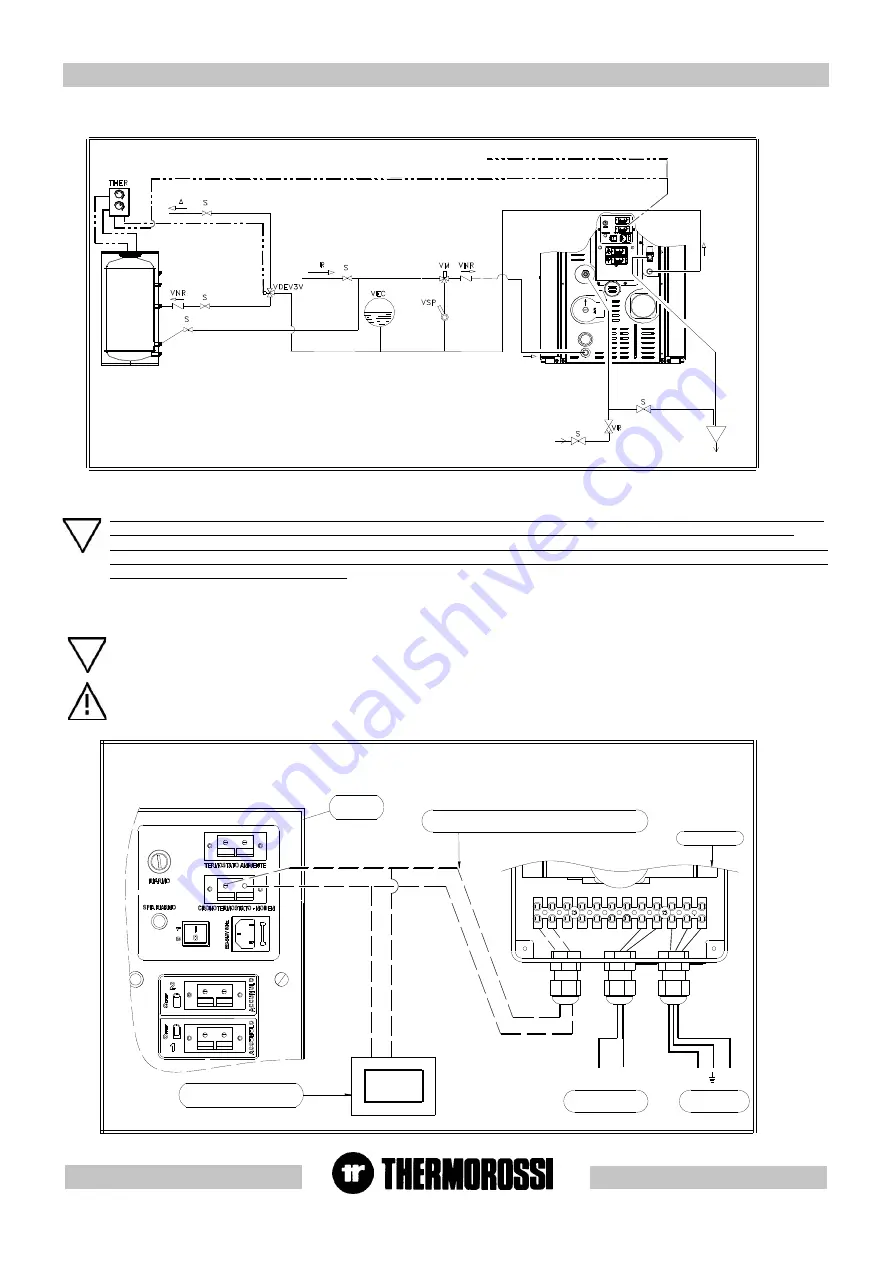

In order to guarantee correct absorption of the heat produced by the generator is it is advisable to use a boiler tube with volume and heat

exchange capacity suitable for the power of the generator.

4 . 6

4 . 6

4 . 6

4 . 6

4 . 6

EXAMPLE OF HYDRA

EXAMPLE OF HYDRA

EXAMPLE OF HYDRA

EXAMPLE OF HYDRA

EXAMPLE OF HYDRAULIC DRA

ULIC DRA

ULIC DRA

ULIC DRA

ULIC DRAWING H

WING H

WING H

WING H

WING H

2

2

2

2

2

0/COMP

0/COMP

0/COMP

0/COMP

0/COMPA

A

A

A

ACT

CT

CT

CT

CT WITH BOILER COILS

WITH BOILER COILS

WITH BOILER COILS

WITH BOILER COILS

WITH BOILER COILS AND USE OF

AND USE OF

AND USE OF

AND USE OF

AND USE OF

THERMOCONTROL (OPTIONAL).

THERMOCONTROL (OPTIONAL).

THERMOCONTROL (OPTIONAL).

THERMOCONTROL (OPTIONAL).

THERMOCONTROL (OPTIONAL).

4 . 6 . 1

4 . 6 . 1

4 . 6 . 1

4 . 6 . 1

4 . 6 . 1 T

T

T

T

T her

her

her

her

her mocontr

mocontr

mocontr

mocontr

mocontr ol electrical connection w

ol electrical connection w

ol electrical connection w

ol electrical connection w

ol electrical connection w her

her

her

her

her e the H2O 25 / COMP

e the H2O 25 / COMP

e the H2O 25 / COMP

e the H2O 25 / COMP

e the H2O 25 / COMPA

A

A

A

ACT 25 boiler is inte

CT 25 boiler is inte

CT 25 boiler is inte

CT 25 boiler is inte

CT 25 boiler is inte g

g

g

g

g rrrrra

a

a

a

a ted

ted

ted

ted

ted

in a plumbing system with boiler coils.

in a plumbing system with boiler coils.

in a plumbing system with boiler coils.

in a plumbing system with boiler coils.

in a plumbing system with boiler coils.

The following is a description of the electric wiring for Thermocontrol and H2O 25 / Compact 25: through this electrical

connection, the shut off action by Thermocontrol automatically switches the diverter valve and also switches off the boiler: if the

system Chronothermostat requires more heat the boiler does not switch off until it has satisfied the heating requirements of the

room. The connections to the diverter valve and system chronothermostat are shown in the diagram and in the following photos.

CAUTION: in order to prevent too many boiler start ups, with consequent reduction in the electrical heater lifetime, the

manufacturer highly recommends using a chronothermostat with a thermal hysteresis of at least 2°C.

" CRONOTERMOSTATO - MODEM " sul pannello posteriore

ON / OFF ECOTHERM (da collegare al connettore

termica minima di 2°C).

Cronotermostato (con isteresi

Pannello

posteriore

Valvola deviatrice

220 V 50 Hz

N

F

220 V 50 Hz

Alimentazione

N

F

Thermocontrol

Caution: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing. There

must be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground wires must

be used to ground all other materials .

See key page XLIII

TB : termostato bollitore

VR : valvola riduttrice di pressione

VM : valvola miscelatrice termostatica punto fisso 55°c.

VDEV3V : valvola deviatrice 3 vie

THER : thermocontrol

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VSP : valvola saracinesca ( da parzializzare in funzione

delle perdite di carico dell'impianto).

DAR

S C

CCI

CCT

A :

heating plant delivery

R:

heating plant return

S :

gate valve

VNR: nonreturn valve

VEC: closed expansion tank for plant protection

VSP: gate valve (throttle according to pressure drop in

the system )

VR:

reducing valve

T B :

reducing valve

VM:

thermostatic mixing valve, fixed point

55°C

VDEV3V: Three-way diverting valve

THER: Thermocontrol

CCI: system chronothermostat contact

CCT: chronothermostat modem contact

DAR: from water mains for make-up

SC:

outlet