Installation, use and maintenance guide

PIDRA 18

Page

22

ENG

1) Electrical power outlet 220V-240V 50Hz

2) Main switch 0/I.

3) Test light for pellet feed motor.

The light comes on simultaneously with the activation of the pellet feed motor.

4) Cap for reset thermostat button.

If the reset thermostat overheats stop the pellet feeder. The appliance must cool down

before you can restart the appliance. After verifying and eliminating the causes of the

event, undo the protective cap and press the button.

5) Protection fuse 3.15 A.

6) Outlet RJ 45 to connect Wi-Fi module.

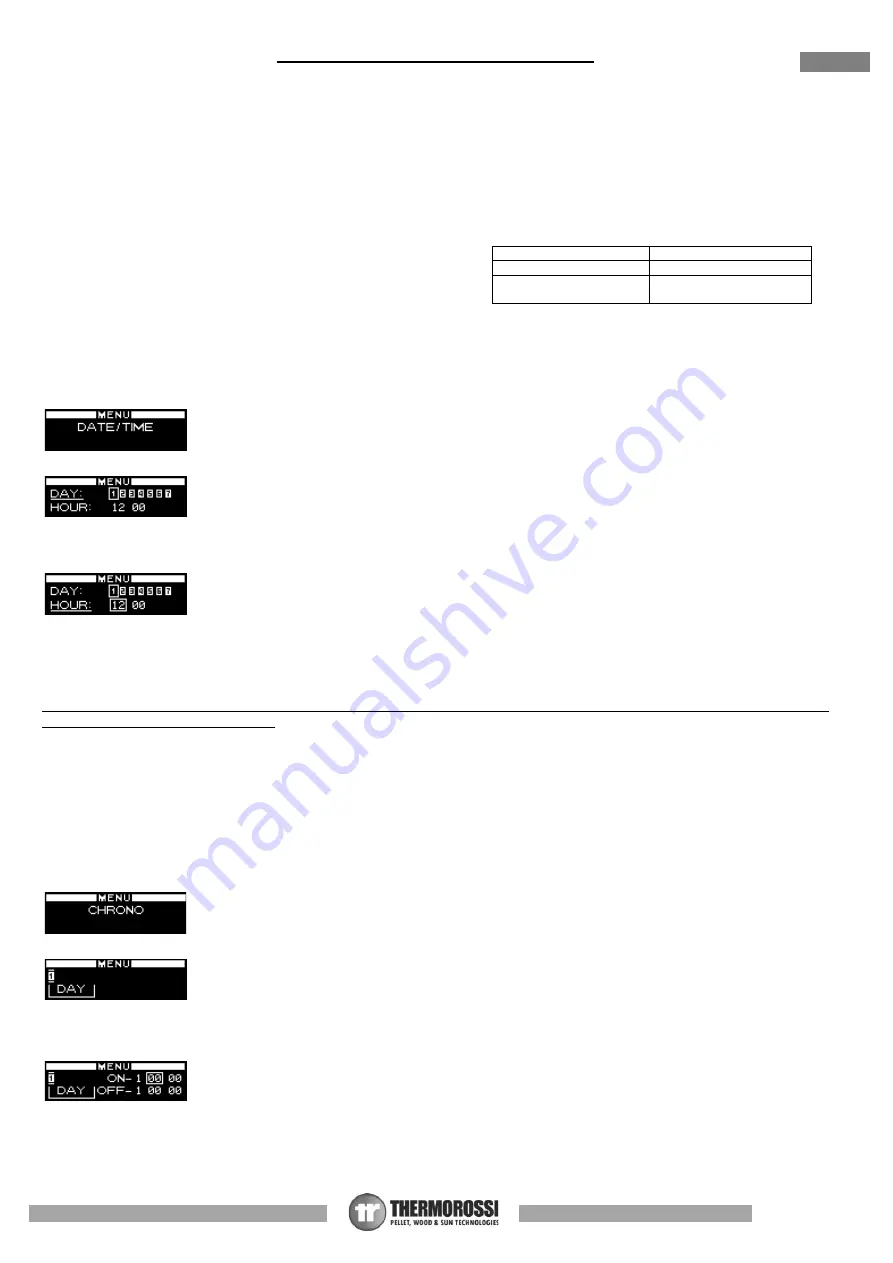

6.3 DATE/TIME: SETTING THE DATE AND TIME

The appliance must be energised and the I/0 switch in position “I".

The current date and time can be set using the DATE/TIME function.

To set the current time and date proceed as follows:

1) Press the

Menu Button

once to view the

following screen:

2) After a few seconds the following screen will appear on the display:

3) Now press the

Scroll Buttons

to change the day of the week; each number corresponds to one day of the week (e.g. 1

corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the selected day of the week press the

Degrees Button

.

Once confirmed, the selector shifts to the hour section while the selected day of the week remains framed:

4) Press the

Scroll Buttons

to change the hour. Once you have set the hour confirm the value by pressing the

Degrees Button.

Once confirmed, the selector shifts to the minutes section. Press the

Scroll Buttons

to set the minutes. To confirm press the

Degrees Button

.

Once confirmed, the date and time setting screen closes automatically and the initial screen returns to the display.

If you confirm the wrong value simply press the

Menu Button

several times to exit the box until the initial screen will appear, and

repeat the procedure described above.

6.4 CHRONO: ON/OFF PROGRAMMING

The appliance must be energised and the I/0

switch in position “I".

The CHRONO function allows you to set the weekly program by setting up to 3 on-off cycles at different times for every day from

Monday through to Sunday.

To set a program follow the procedure described below:

1) Press the

Menu Button

twice

quickly to view the following screen:

After a few seconds the following screen will appear on the display:

2) Press the

Scroll Buttons

to select the day of the week on which you want to set the program. Each number corresponds to one

day of the week (e.g. 1 corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the selected day of the week for

the programming press the

Degrees Button

. The following screen will appear:

3) Now press the

Scroll Buttons

to select the hour at which you wish the appliance to start up automatically (ON1). Once the hour

is set confirm the value by pressing the

Degrees Button.

When scrolling the ON1 values the OFF1 values will scroll as well; this

is to avoid setting a shut off time that is earlier than the start up time.

Once confirmed, the selector shifts to the minute section of ON1. Press the

Scroll Buttons

to set the minutes for the first start

up. Confirm by pressing the

Degrees Button

.

Legenda

Key

RIARMO

RESET

SPIA MOTORIDUTTORE

GEARMOTOR

INDICATOR