Page 21

Installation, use and maintenance guide

SlimQuadro Idra 14

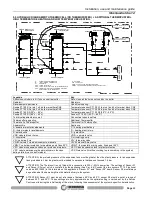

5.4 EXAMPLE OF HYDRAULIC DIAGRAM WITH BOILER COILS AND HEATING SYSTEM

Legenda

Key

Contatto cronotermostato

Chronothermostat contact

Impianto

System

Contatto cronotermostato modem della caldaia

Chronothermostat modem contact of the stove

SB ai pin 5 e 6 della morsettiera CN5

SB to pins 5 and 6 of the terminal block CN5

Alimentazione dalla morsettiera CN3 pin 5 (neutro), pin 7 (L1), pin 8

(L2)

Power supply from the terminal block CN3 pin 5 (neutral), pin 7 (L1),

pin 8 (L2)

Scarico

Outlet

APPARECCHIO

APPLIANCE

A: andata impianto riscaldamento

A – heating plant delivery

R: ritorno impianto riscaldamento

R – heating plant return

S: saracinesca

S – gate valve

VNR: valvola di non ritorno

VNR – nonreturn valve

VEC: vaso di espansione chiuso per protezione impianto

VEC: closed expansion tank for plant protection

VSP: valvola saracinesca (da parzializzare in funzione delle perdite

di carico dell’impianto)

VSP: Gate valve (throttle according to pressure drop in the system)

SB: sonda acqua calda sanitaria

SB: domestic hot water sensor

VR: valvola riduttrice di pressione

VR: pressure reducing valve

VM3VT: valvola miscelatrice termostatica punto fisso 55°C

VM3VT: thermostatic mixing valve, fixed point 55°C

VDEV3V: valvola deviatrice 3 vie alimentata in chiusura e anche in

apertura

VDEV3V: 3 way diverting valve powered at closure and also at

opening

Dall’acquedotto per reintegro

From water mains for make-up

In order to guarantee correct absorption of the heat produced by the generator it is advisable to use a boiler tube with volume and

heat exchange capacity suitable for the power of the generator. The boiler tube must have a minimum capacity of 300l. In any case

the boiler tube must be capable of absorbing all the power that the generator is capable of delivering.

If this rule is not observed, the generator could raise the water temperature to such a point as to activate the safety limit thermostat

which stops the fuel from dropping into the burner and therefore forces the appliance to shut off.

The installer is required to install a valve that switches over to the system, powered by the stove’s control unit, which trips when the

boiler is thermally “satisfied ”. Consequently, the plant must be designed in such a way that the hot water produced by the generator

can reach the various rooms by acting on the zone valves.

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric potential (Volt) between the generator earth and the plant’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

S

R

S

VN R

S

VN R

S

A

VDEV3 V

VEC

VM3 VT

Co n t a t t o Cr o n o t e r m o s t a t o

Mo d e m d e l l a c a l d a i a

Co n t a t t o Cr o n o t e r m o s t a t oIm p i a n t o

V SP

p e r r e i n t e g r o

Da l l ' a c q u e d o t t o

s c a r i c o

S

VR

A

P

P

A

R

E

C

C

H

IO

A

R

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VSP : valvola saracinesca ( da parzializzare in funzione

delle perdite di carico dell'impianto).

SB : sonda acqua calda sanitaria

VR : valvola riduttrice di pressione

VM3VT : valvola miscelatrice termostatica punto fisso 55°c.

VDEV3V : valvola deviatrice 3 vie alimentata in chiusura e anche in apertura.

Alimentazione dalla morsettiera CN3

pin 5 (neutro), pin 7 (L1) , pin 8 (L2)

SB ai pin 5 e 6 della

morsettiera CN5.