T9901085-1-3 UK

Page 10 of 38

Recommended

250mm min.

for pipework

INSTALLATION OF THE AIR CURTAIN

The air curtain is designed to be surface mounted inside a building and located

horizontally over a doorway. It must not be installed on the outside of the building,

or built into a cabinet or recessed in anyway.

Location

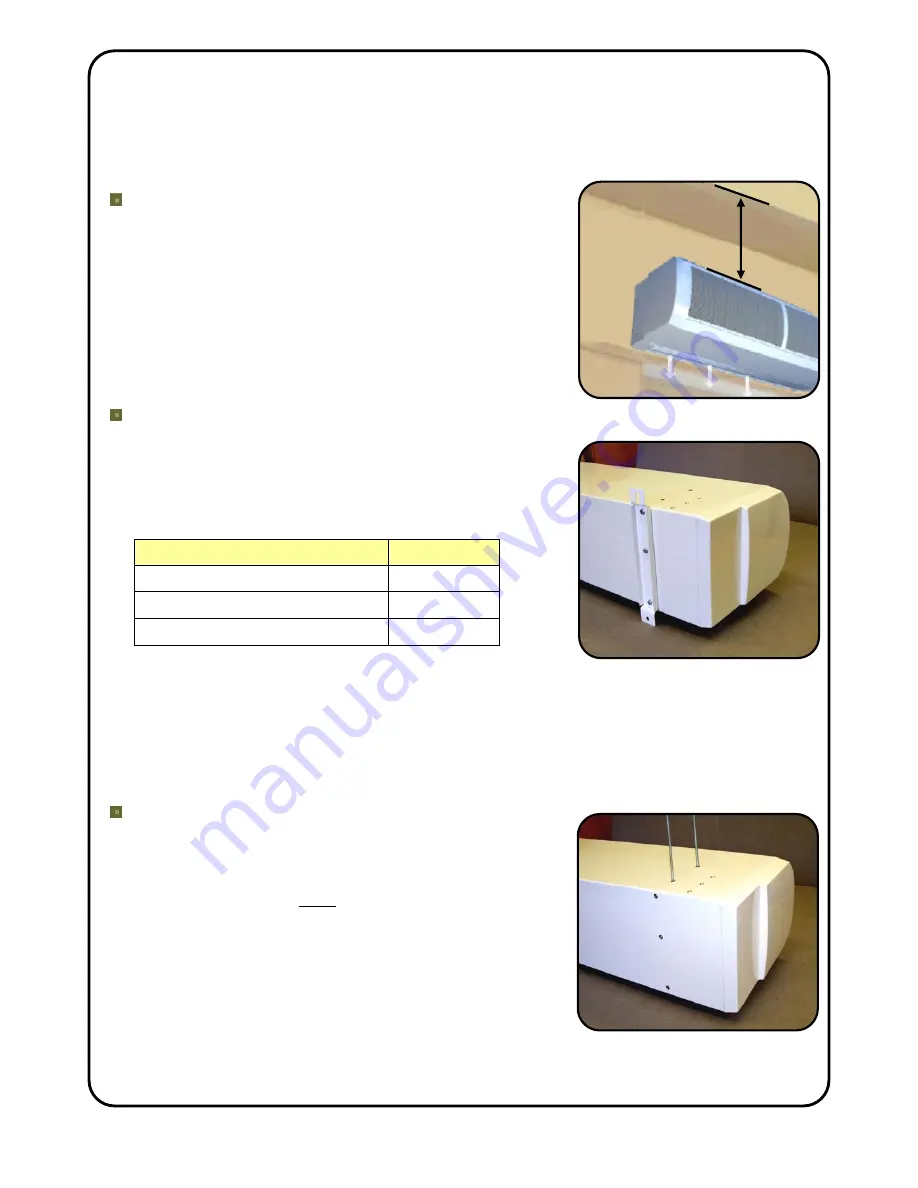

The air curtain must be mounted so the discharge grille is

located up to 3.2m maximum above floor level and as

close to the doorway as possible. It must be installed level

or condensate may leak out if used for cooling. It is

recommended to leave a gap of 250mm minimum above

the air curtain to allow for pipework brazing operations.

Beware of doorway top edges, structural beams, door

opening/closure devices, etc. which may interfere with the

air stream and affect the location of the unit.

Wall Fixing

Bolt all of the wall brackets supplied to the rear face of the

unit as shown in the adjacent picture using the M10 bolts

supplied. Suitable wall fixing bolts (not supplied) need to

be used to fix the brackets to the wall, taking into account

the type of wall and the weight of the unit*, see table:

Air Curtain

Weight (kg)

HP1000 DXE

46

HP1500 DXE

67

HP2000 DXE

84

Step 1.

Refer to Figure 2, Page 11 for mounting details

and drill the fixing points in the wall.

Step 2.

Screw in the top wall bolts leaving a small gap between the head and the wall.

Lower the unit onto the bolts via the key-hole slots in the top of the wall brackets and then

screw in the bottom wall bolts.

Step 3

. Ensure all fixing bolts are tightened and the air curtain is safely secured to the

wall.

Ceiling Suspension

M10 threaded inserts are provided in the top face of the

unit (see Figure 2, Page 11 for positions) so it can be

suspended on M10 threaded hanging rods (not provided).

All suspension points must be used. Ensure each of the

hanging rods is secured onto a suitable structure that can

support the weight of the unit (see table above)

*

. Screw

the hanging rods into the inserts by a minimum or 20mm

and fit locking nuts (not provided) to prevent the rod

rotating and coming away from the casing. Do not screw

the hanging rod too far in or it could interfere with internal

components.

*

It is the sole responsibility of the installer to ensure that the building fixing locations and suspension system

used are suitable for the air curtain being installed.