26

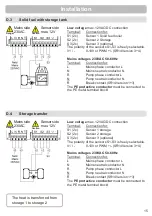

5. - Settings

The necessary basic settings required for

the control function are made in menu “5.

Settings”.

Caution

This does not under any circum-

stances replace the safety facilities

to be provided by the customer!

The menu is closed by pressing “esc” or

selecting “Exit settings”.

Settings

Various settings can be made depending on the selection of hydraulic variant.

The following pages contain generally valid descriptions for the settings.

Caution

5.1 - Tmin S1

Enable/start temperature at sensor 1

If this value is exceeded at sensor 1 and the other conditions are also met, then the

controller switches the pump and/or valve on. If the temperature at sensor 1 drops

below this value by 5K, then the pump and/or valve is switched off again.

Setting range: from 0°C to 99°C / default setting: 20°C (solid fuel boiler: 60°C)

5.4 - Tmax S2

Switch-off temperature at sensor 2

If this value is exceeded at sensor 2 and the other conditions are also met, then the

controller switches the pump and/or valve off. If sensor 2 falls below this value again

and the other conditions are also met, then the controller switches the pump and/or

valve on again.

Setting range: from Off (Solid fuel boiler), 0°C to 99°C (can be switched off in thermo-

stat systems)

Default setting: 60°C (swimming pool: Default: 30°C)

Danger

Temperature values which are set too high can lead to scalding or dam-

age to the system. Scalding protection must be provided by the cus-

tomer!

Caution

When using application 3 with solid fuel boiler, at least 60°C should

be set. Consider instructions of boiler manufacturer!