29

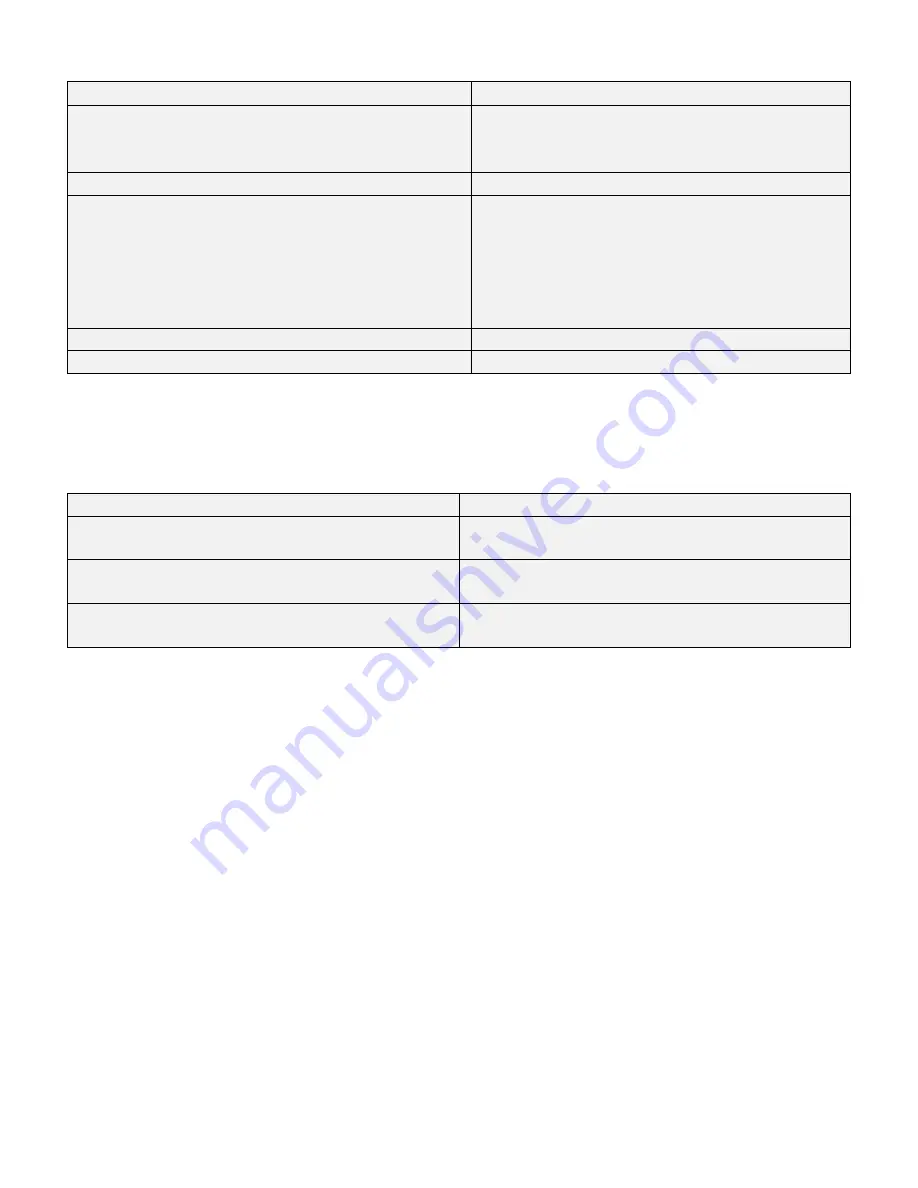

T257P System Wetted Path Materials

10.4

Heat Transfer Manifold

Aluminum with Electro less-‐Nickel plating

Tubing

1.

Pre formed metal tubing

2.

Flexible Hose Tubing

304 Stainless Steel

Synthetic rubber

Temperature Sensor

316 Stainless Steel

Colder CPC Connectors

1.

Acetal body and valves, and 316 Stainless

Steel springs and Buna O-‐ring

2.

Chrome plated brass body, Acetal Valve,

316 Stainless Steel springs and Buna O-‐

ring

Coolant Reservoir

HDPE with Silicon O-‐ring

Level Switch

PVC with Buna O-‐ring

T257P System – Conformance Information

10.5

Electrical Safety:

IEC 61010-‐1 3

rd

Ed

Electromagnetic Compatibility (EMC):

IEC 61326-‐1 2

nd

Ed

Waste Electrical & Electronic Equipment (WEEE):

Directive 2002/96/EC

Restriction of Hazardous Substance (RoHS):

Directive 2002/95/EC

T257P System – Guidance and Manufacture’s Declaration – Electromagnetic

10.6

Emissions

This device has been tested and found to comply with the limits for Electrical equipment for

measurement, control and laboratory use, per IEC 61326-‐1. These limits are designed to provide

reasonable protection against harmful interference in typical installation for the stated use.

This equipment generates and radiates radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to other devices in the vicinity.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to other devices, which can be determined by turning the equipment

off and on, the user can try to correct the interference by one or more of the following measures:

•

Reorient or relocate the receiving device.

•

Increase the physical separation between the equipment and other device(s).

Summary of Contents for T257P

Page 1: ...T257P Precision Chiller User Manual...

Page 8: ...8 Device Illustration 3 2...

Page 27: ...27 T257P System Performance 10 2 Note...

Page 33: ...33...