Owner's Manual for Thern TSSBW Series Spur Gear Hand Winches

page 13

A10191-0309

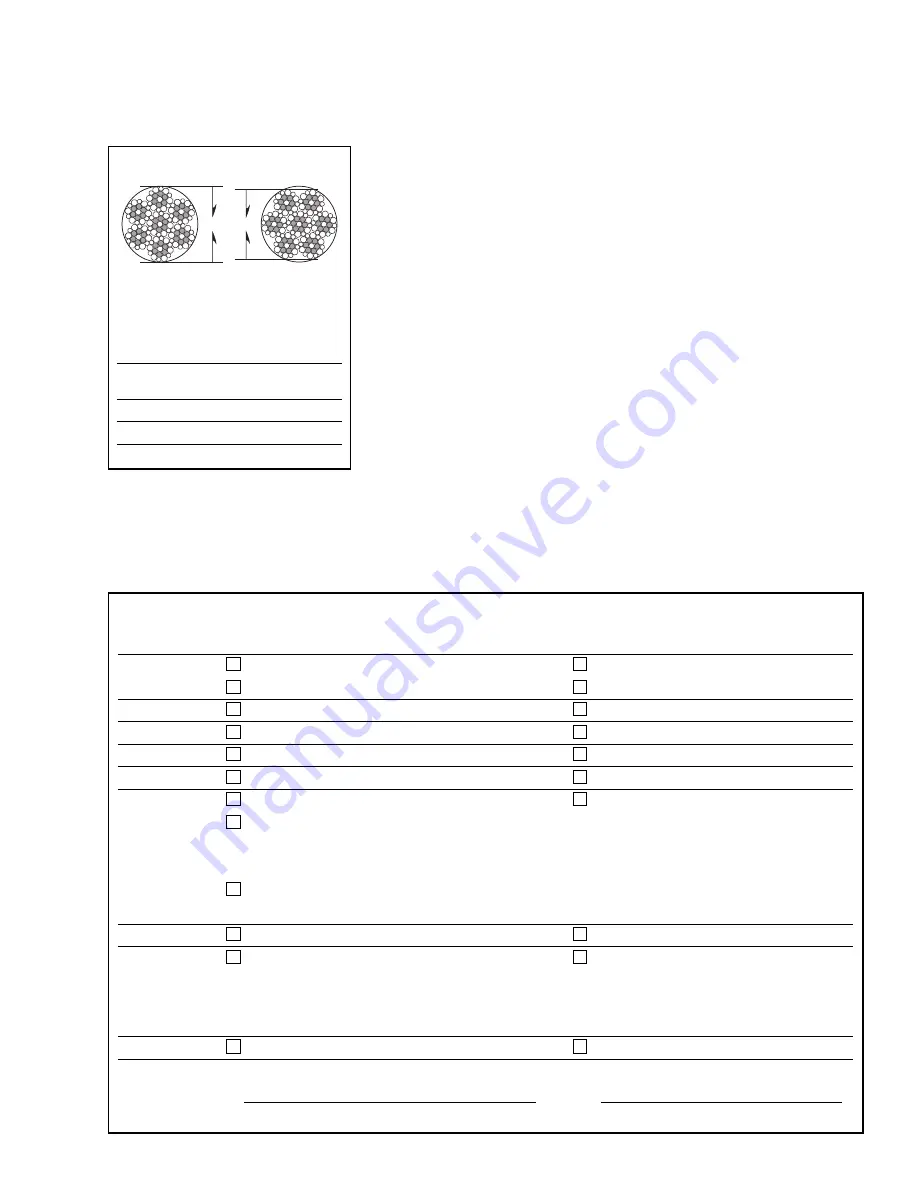

Figure 8 – Rope Diameter

di ame ter

in cor rect

correct

The wire rope assembly must be

replaced if the diameter measures

less than the minimum diameter at

any point.

wire rope

diameter

minimum diameter

1/8 in

7/64 in (.1094 in)

3/16 in

11/64 in (.1719 in)

1/4 in

15/64 in (.2344 in)

Table 1 – Inspection Checklist

damages

problems

general

fi nish weathered, fl aking, otherwise damaged

winch jerks or hesitates during operation

parts cracked, bent, rusted, worn, otherwise damaged

unusual noises, other signs of malfunction

fasteners

stripped threads, bent, worn, otherwise damaged

loose, not tightened to proper torque

gears

excessively worn, cracked, corroded, otherwise damaged

loose or improperly lubricated

brake assembly

brake corroded, cracked, worn, otherwise damaged

brake does not operate properly

drum

anchor hole worn, distorted, otherwise damaged

excessive movement or backlash

wire rope

bent, crushed, otherwise damaged

wire rope loosely or unevenly wound

broken wires, see fi gure 5

replace if more than 6 wires in one lay,

number per strand =

or 3 wires in one strand in one lay, are broken

number per lay =

diameter reduced, see fi gure 7

replace if diameter is excessively worn

diameter =

end connections

corroded, rusted, worn, otherwise damaged

not securely attached

load hook

twisted, bent, worn, otherwise damaged, see fi gure 6

hook latch fails to close when released

replace if twist is 10 degrees or more

twist =

replace if throat width is 15% larger than nominal

throat width =

replace if thickness is 10% less than nominal

thickness =

labels and plates

dirty, illegible, otherwise damaged

loosely attached or missing

comments:

authorized signature:

date

checked boxes indicate damage or problem in need of repair

g

INSTALL THE WIRE ROPE.

h

TEST WINCH PERFORMANCE by operating the winch with a load equal

to the load rating.

• Listen for unusual noises, and look for signs of damage as you op er ate the

winch.

• Make sure the wire rope winds evenly and tightly onto the drum. If it is

loose or uneven, rewind it before continuing.

• Observe the rotating drum, look for signs of loose or misaligned bear ings.

• Make sure the handle rotates freely in both directions.

Completely correct all problems before continuing. Use the trou ble shoot ing

chart to help determine the cause of certain problems. See table 2.