Owner's Manual for Thern TSSBW Spur Gear Hand Winches

page 6

A10191-0309

1.3

Installing the Wire Rope

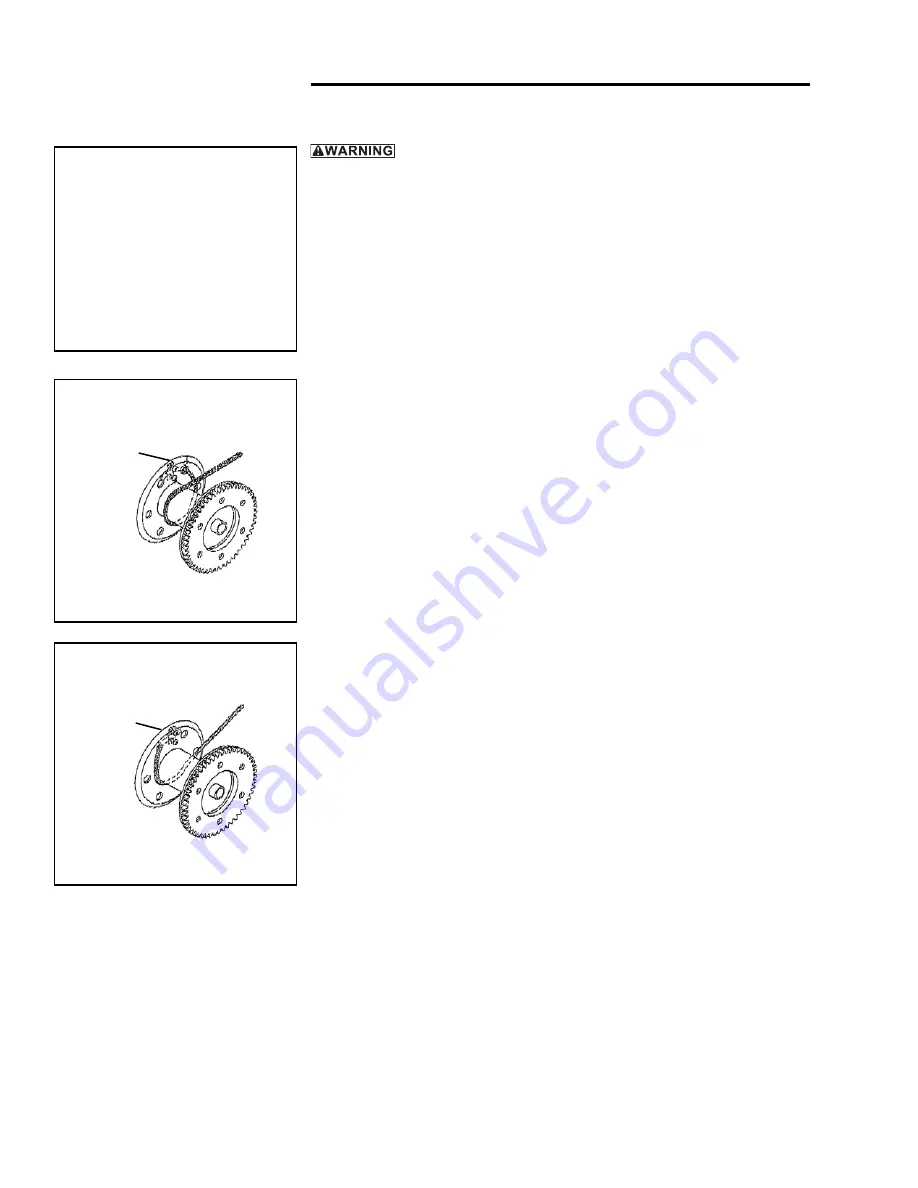

Install the wire rope so it is wound correctly as shown, or the winch will not

work properly, and could release the load.

Install the wire rope securely to the winch drum. A poorly secured wire rope

could come loose from its anchor and could release the load.

1.3.1

PURCHASE THE PROPER WIRE ROPE for your application. Keep the

following in mind when selecting a wire rope. Contact a reputable wire rope

sup pli er for help.

a

BREAKING STRENGTH of new wire rope should be at least 3 times

great er than the largest load placed on the winch. If loads are lifted or pulled

on an incline, the breaking strength must be at least 5 times greater than the

largest load. These are minimum values and will vary with the type of load

and how you are moving it.

b

WIRE ROPE LAY must agree with the winding direction of the drum to help

insure proper winding.

c

WE RECOMMEND 7 x 19 stainless steel wire rope diameter of 3/16 inch

for TSSBW600 and TSSBW900 models and 1/4 inch for TSSBW1300

models.

1.3.2

ANCHOR THE WIRE ROPE to the drum using the fl ange clip.

a

PASS THE END OF THE WIRE ROPE through the hole in the fl ange.

b

INSERT THE CARRIAGE BOLT, loop the wire rope around the bolt, and

install the clip so the wire rope is held by the curves of the clip.

c

INSTALL THE JAM NUT and tighten it until the wire rope is fl attened

against the drum fl ange.

1.3.3

TURN THE HANDLE CLOCKWISE to wind wire rope onto the drum. If

wire rope unwinds from the drum when the han dle is rotated clock wise, the

wire rope is installed incorrectly.

Install the wire rope correctly before

con tinu ing.

1.3.4

WIND FOUR FULL WRAPS of wire rope onto the drum by operating the

winch while holding the wire rope taught.

These wraps serve as anchor

wraps and must remain on the drum at all times.

Important!

• Use wire rope and other rigging

equipment rated for the size of the

largest load you will be moving.

• Do not drag the wire rope

through dirt or debris that could

cause damage, or poor operation.

• Always wear protective clothing

when handling wire rope.

Figure 3 – Wire Rope

Installation

Figure 4 – Wire Rope

Installation

overwound installation shown

for models 600 and 900

fl ange clip

anchor

fl ange clip

anchor

underwound installation shown

for model 1300