Owner's Manual for Thern TSSBW Spur Gear Hand Winches

page 8

A10191-0309

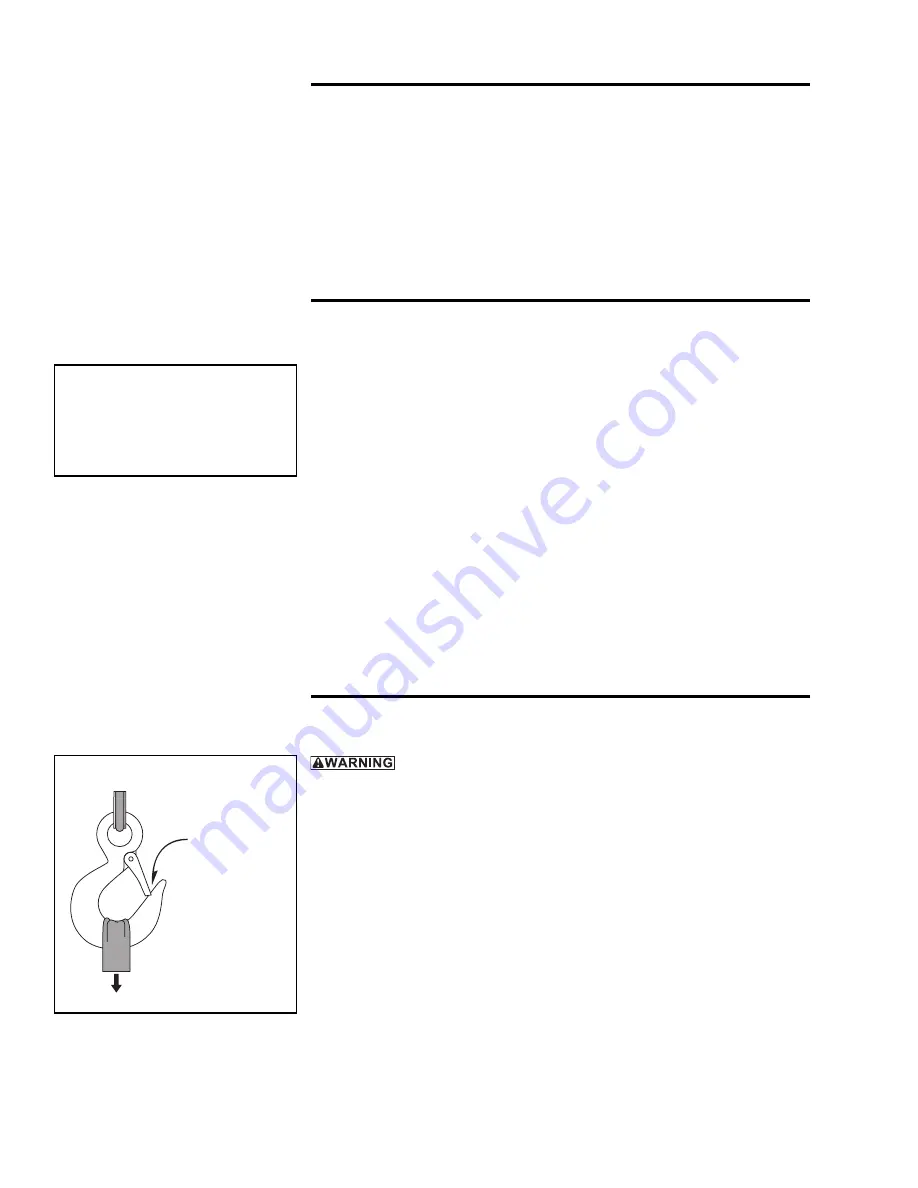

Figure 5 – Attaching Load

latch closed

tight against

hook

sling seated in

saddle of hook

Important!

• When determining whether the

load will exceed the load rating,

consider the total force required

to move the load.

2.2

Breaking-In the Winch

2.2.1

BREAK-IN OCCURS

during the fi rst 10 hours of normal operation. During

break-in, mating surfaces become polished, and clearances increase. This is

desired for effi cient operation of bearings and gears.

2.2.2

INSPECT THE WINCH following break-in according to the Instructions for

Periodic Inspection.

2.3

Preparing for Operation

2.3.1

CONSIDER THE OPERATION. Do not begin until you are sure you can

perform the entire operation without hazard.

2.3.2

INSPECT ALL COMPONENTS of the system.

a

INSPECT THE WINCH and other equipment according to the Instructions

for Frequent Inspection.

b

OPERATORS must be in good health, alert, thoroughly trained in operat-

ing the equipment, and properly clothed (hard hat, safety shoes and safety

glass es, no loose clothing).

c

THE LOAD must be clear of other objects and free to move. Make sure the

load will not tip, spin, roll away, or in any way move uncontrollably.

2.3.3

KNOW YOUR LOAD and make sure you do not exceed the load rating of

the winch or any other equipment in the system.

2.4

Attaching the Load

Do not wrap the wire rope around the load. This damages the wire rope and

could cause the load to escape. Use a sling or other approved lifting device.

2.4.1

CLEAR OBJECTS from the path of the load so you can move it freely and

observe it at all times during the operation.

2.4.2

ATTACH THE LOAD using a nylon sling, or other approved lifting de vice.

Follow the recommendations of the sling manufacturer.

a

SEAT THE SLING in the saddle of the hook with the hook latch com plete ly

closed. See fi gure 5.

b

CENTER THE LOAD on the hook so it will remain balanced and not tip or

rotate to one side.